Ball head milling cutter, ball head double-edged milling cutter and processing method

A ball-end milling cutter and ball-end technology, which is applied in the direction of milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the service life of the tool and the poor quality of the processed surface, so as to prolong the life of the milling cutter, improve the quality, and improve the The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

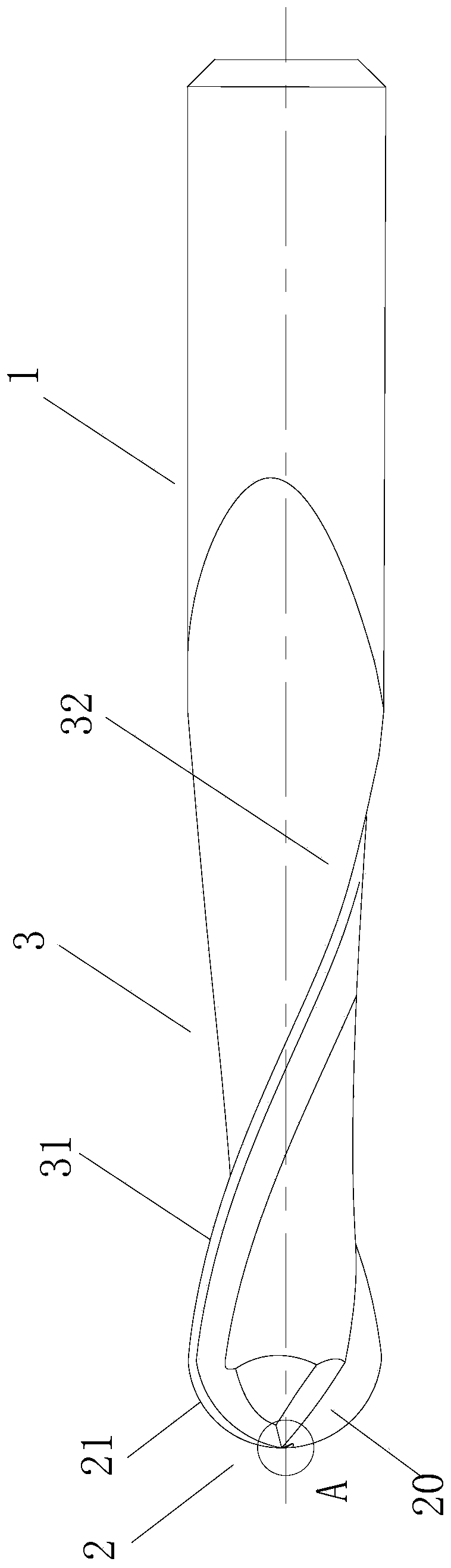

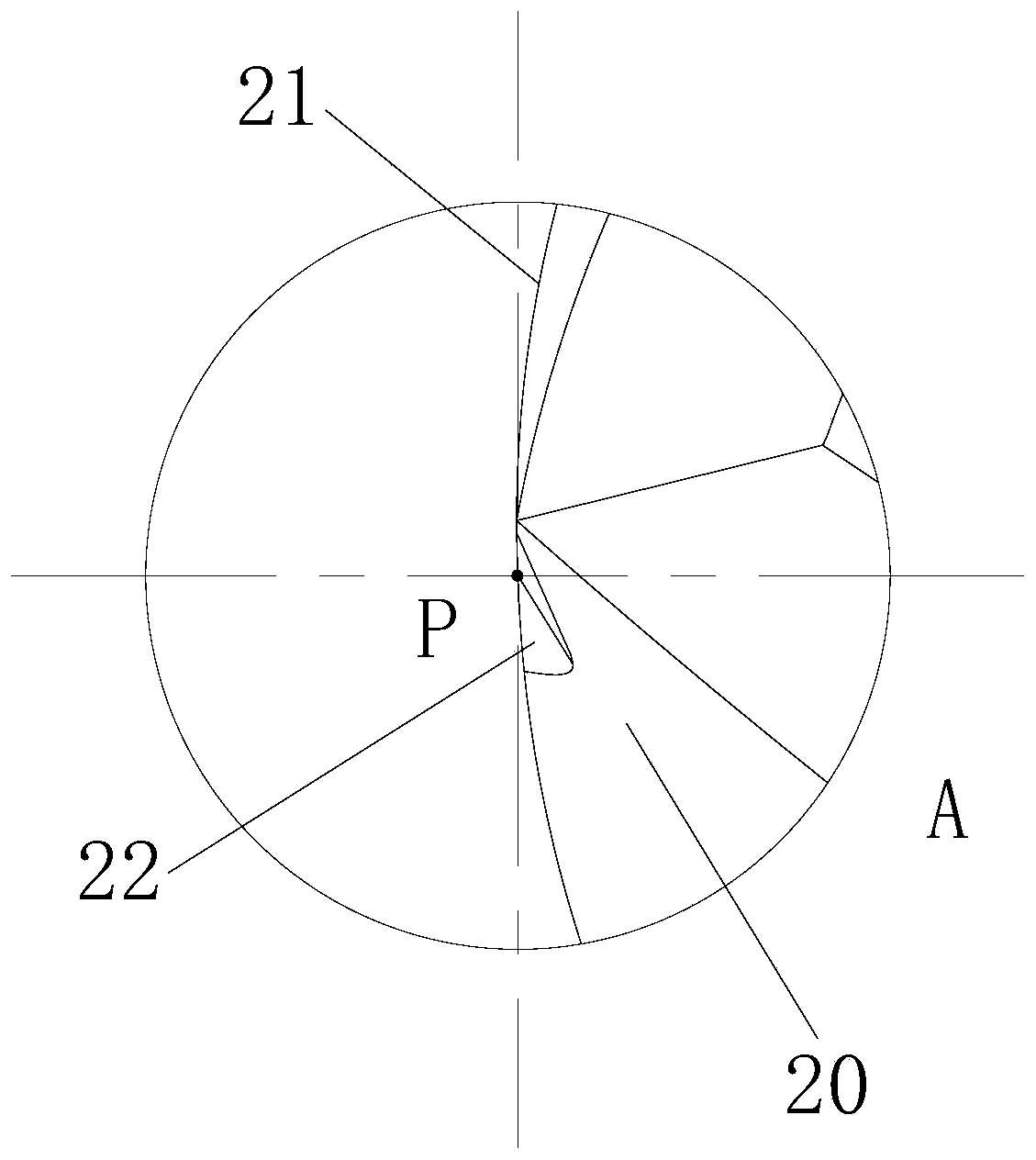

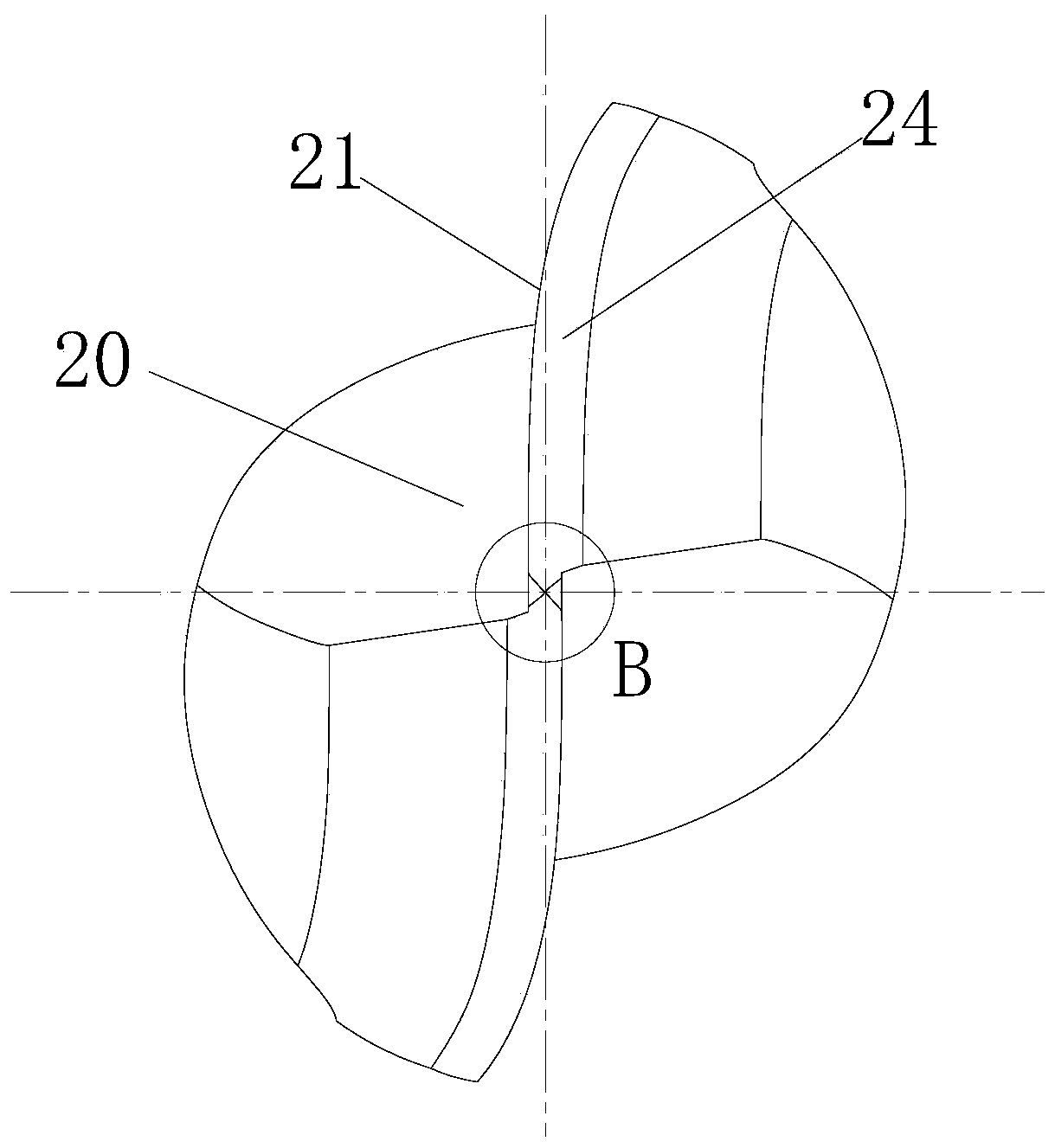

[0077] Such as Figure 1 to Figure 4 , Figure 7 with Figure 8 As shown, this embodiment corresponds to the above-mentioned arrangement mode (4) of the core cutting edge 23. There are two ball-end cutting edges 21, and a boundary line 26 is formed after the flank faces 24 of the two ball-end cutting edges 21 intersect. 26 passes through the ball vertex P of the ball cutting part 2, and the center of the boundary line 26 coincides with the ball vertex P, and there are two core grooves 22, wherein the ball cutting edge 21 and the core groove 22 are about the axis of the tool body 1 Symmetrically distributed along the circumferential direction, two ball-end cutting edges 21 are arranged at intervals of 180° along the circumference, and the first groove wall 221 of each core groove 22 intersects with the flank surface 24 of the corresponding ball-end cutting edge 21 to obtain two The core blade 23, wherein, the ball point apex P divides the boundary line 26 into two line segmen...

Embodiment 2

[0079] Such as Figure 1 to Figure 3 , Figure 5 , Figure 7 with Figure 8 As shown, this embodiment corresponds to the arrangement method (8) of the above-mentioned core cutting edge 23, and there are two ball-end cutting edges 21. Coincidentally, the other end point of each core edge 23 is located on the corresponding ball-end cutting edge 21 , and there is an included angle between the core edge 23 and the boundary line 26 .

Embodiment 3

[0081] This embodiment corresponds to the arrangement method (4) of the above-mentioned core blade 23. There are two ball-end cutting edges 21. The difference from Embodiment 1 is that there is only one core groove 22, and the ball-end cutting edge 21 is about the axis of the tool body 1. The center is distributed symmetrically along the circumferential direction, and the two ball-end cutting edges 21 are arranged at intervals of 180° along the circumferential direction. The first groove wall 221 of the core groove 22 intersects with the flank surface 24 of any one of the ball-end cutting edges 21 to obtain a core edge 23 . Wherein, in an ideal state, the end point of the core edge 23 near the vertex P of the ball will coincide with the vertex P of the ball. However, in practical applications, due to the influence of processing conditions (such as the thickness of the grinding wheel), the end points of the core cutting edge 23 may not coincide with the apex P of the ball head,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com