Field rapid and accurate cutting method for aerated concrete blocks

A block and precise technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of material waste and cutting quality, and achieve the effect of light weight, simple operation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

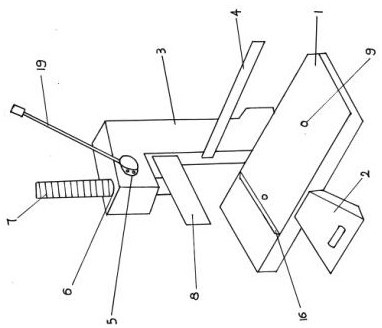

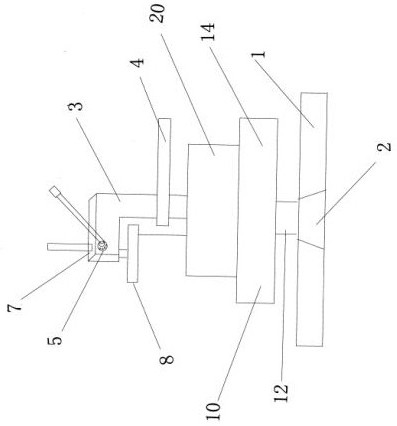

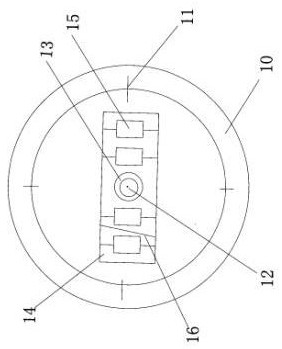

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

[0031] A portable cutting device for aerated concrete blocks, including a rectangular base plate 1 and an inverted L-shaped bracket 3, a pedal tongue plate 2 is connected to the center of the front side elevation of the rectangular base plate 1, and the rectangular base plate 1 is connected with an inverted L-shaped support 3 at the center of the rear elevation of 1, and on the horizontal cantilever at the top of the inverted L-shaped support 3, a pair of support bearings 5 for the central axis of the gear are arranged, and a pair of support bearings 5 for the central axis of the gear In the bearing 5, a gear is provided. On the top horizontal cantilever of the inverted L-shaped bracket 3 on the left side of the gear, along the vertical direction up and down, a rack is also provided to pass through the through hole 6, and the rack passes through the through hole 6. , the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com