Improved smectic phase light dimming glass

A technology of dimming glass and smectic phase, applied in optics, nonlinear optics, instruments, etc., can solve the problems of large size, high energy loss, corrosion, etc., and achieve the effect of ensuring driving performance, reducing costs, and avoiding local heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

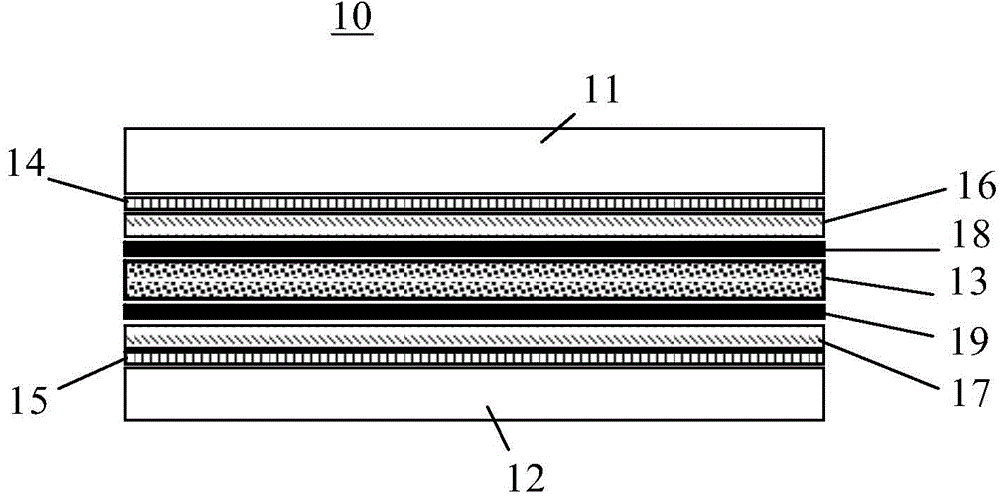

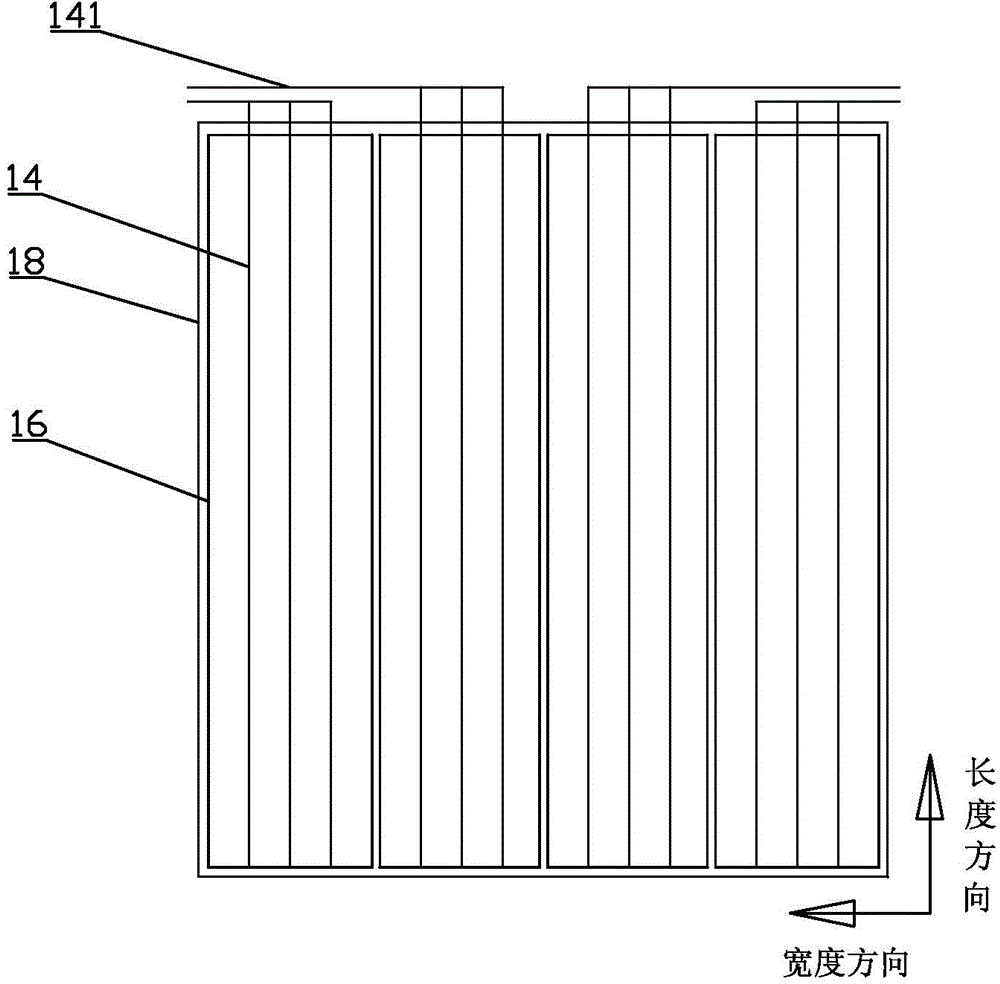

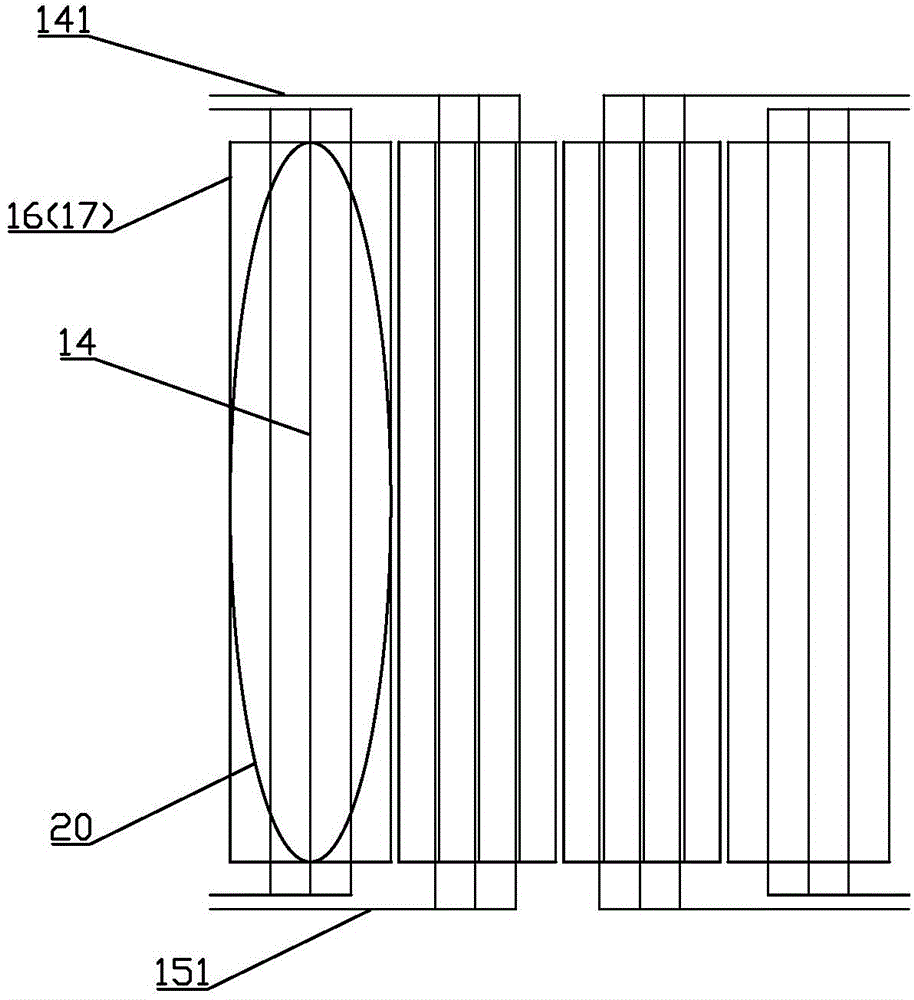

[0018] Such as Figure 1 to Figure 2 As shown, the improved smectic phase switchable glass 10 of the present invention includes a stacked first base layer 11, a liquid crystal mixed layer 13, and a second base layer 12, and the surface of the first base layer 11 facing the liquid crystal mixed layer 13 is plated with Sheet-shaped, strip-shaped transparent electrodes 16, the surface of the second base layer 12 facing the liquid crystal mixed layer 13 is plated with sheet-shaped, strip-shaped transparent electrodes 17, and the transparent electrodes 16 are evenly distributed with resistance values smaller than the transparent electrodes. The resistance value of 16, the current flowing through itself (referring to the electrode line 14) quickly can spread all over the multiple linear electrode lines 14 of the transparent electrode 16. The current flowing through itself (referring to the electrode wire 15) can quickly spread over the multiple linear electrode wires 15 of the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com