Technology for forming oxidation films with consistent thickness

An oxide film, consistent technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of inconsistent thickness of tantalum pentoxide dielectric film, affecting product qualification rate, etc., to ensure thickness consistency, electric field The effect of uniform strength and reduced pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

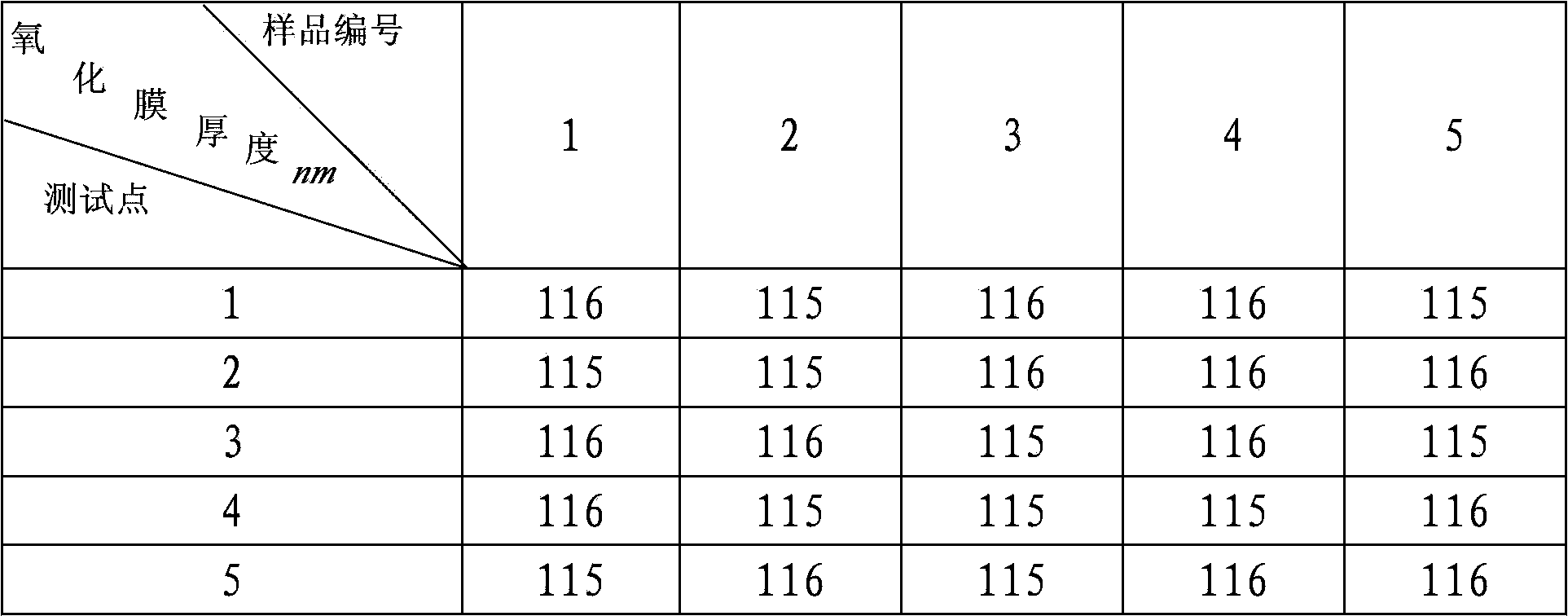

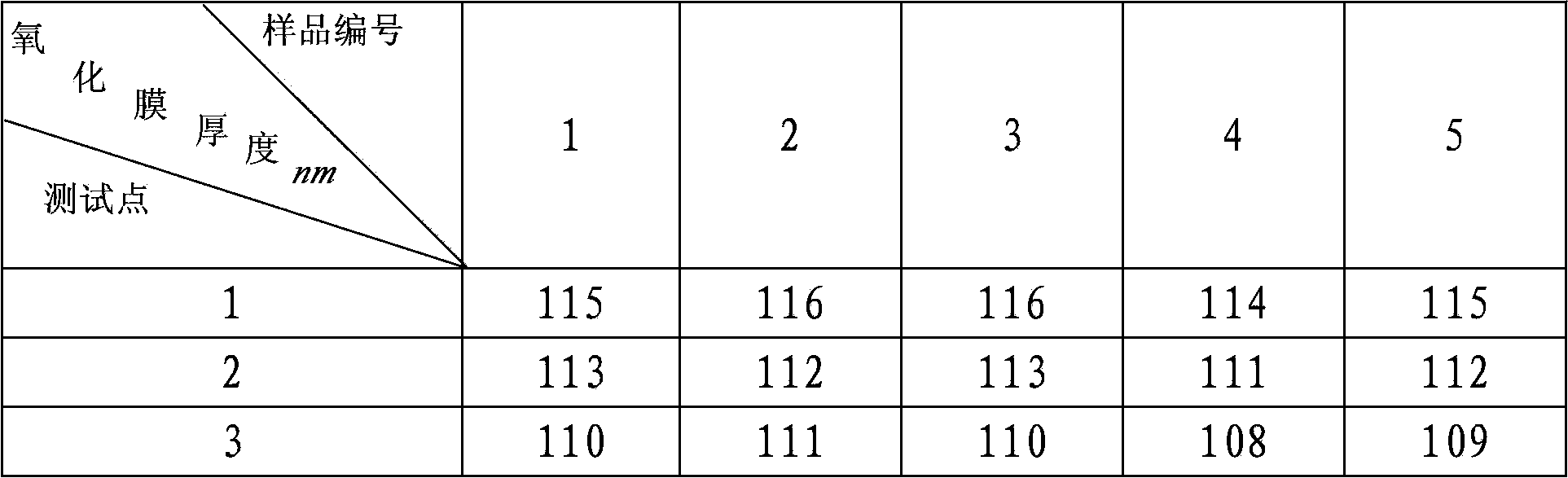

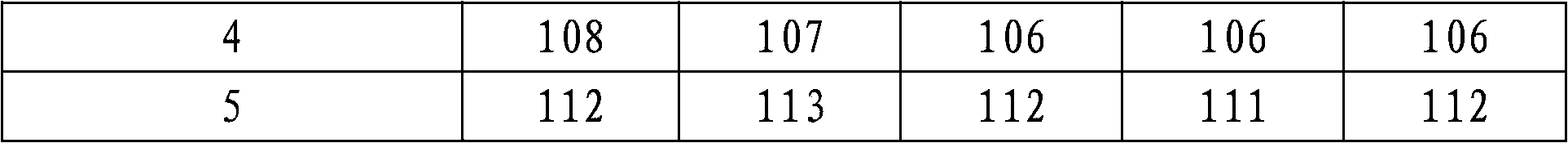

Examples

Embodiment Construction

[0013] The technical solution of the present invention is further described below in conjunction with the examples, but the scope of protection is not limited to the description.

[0014] A technique for forming an oxide film with a consistent thickness, comprising the following steps:

[0015] (1) Weld the sintered tantalum anode block evenly on the conductive metal strip, and then place the conductive metal strip on the bracket in turn;

[0016] (2) Put the bracket with the conductive metal strips into the electrolytic tank, which is filled with the electrolyte in advance;

[0017] (3) Make a "King"-shaped wire frame with wires, the size of the wire frame is equivalent to the size of the bracket, and the center of the "King"-shaped wire frame is the power connection point;

[0018] (4) Place the "Wang" character wire frame overlappingly on the bracket and make close contact with the metal strip spot-welded with the tantalum anode block;

[0019] (5) Connect the positive po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com