Microwave type intelligent grain moisture detector

A technology for grain moisture and detectors, which is applied in the direction of using microwaves to test moisture content, instruments, and sample preparation for testing. It can solve problems such as low precision, interference, and reduced moisture detection accuracy, so as to ensure consistency of thickness and improve detection. Accuracy, effects of avoiding absorption and reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

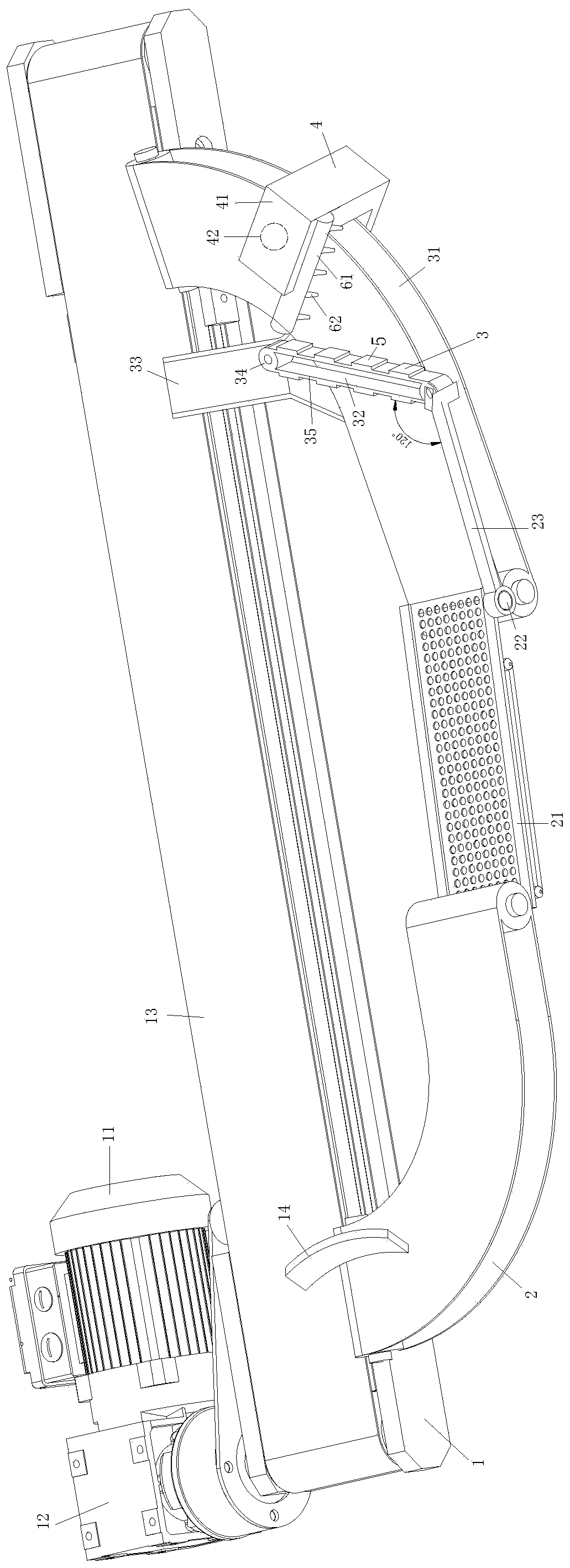

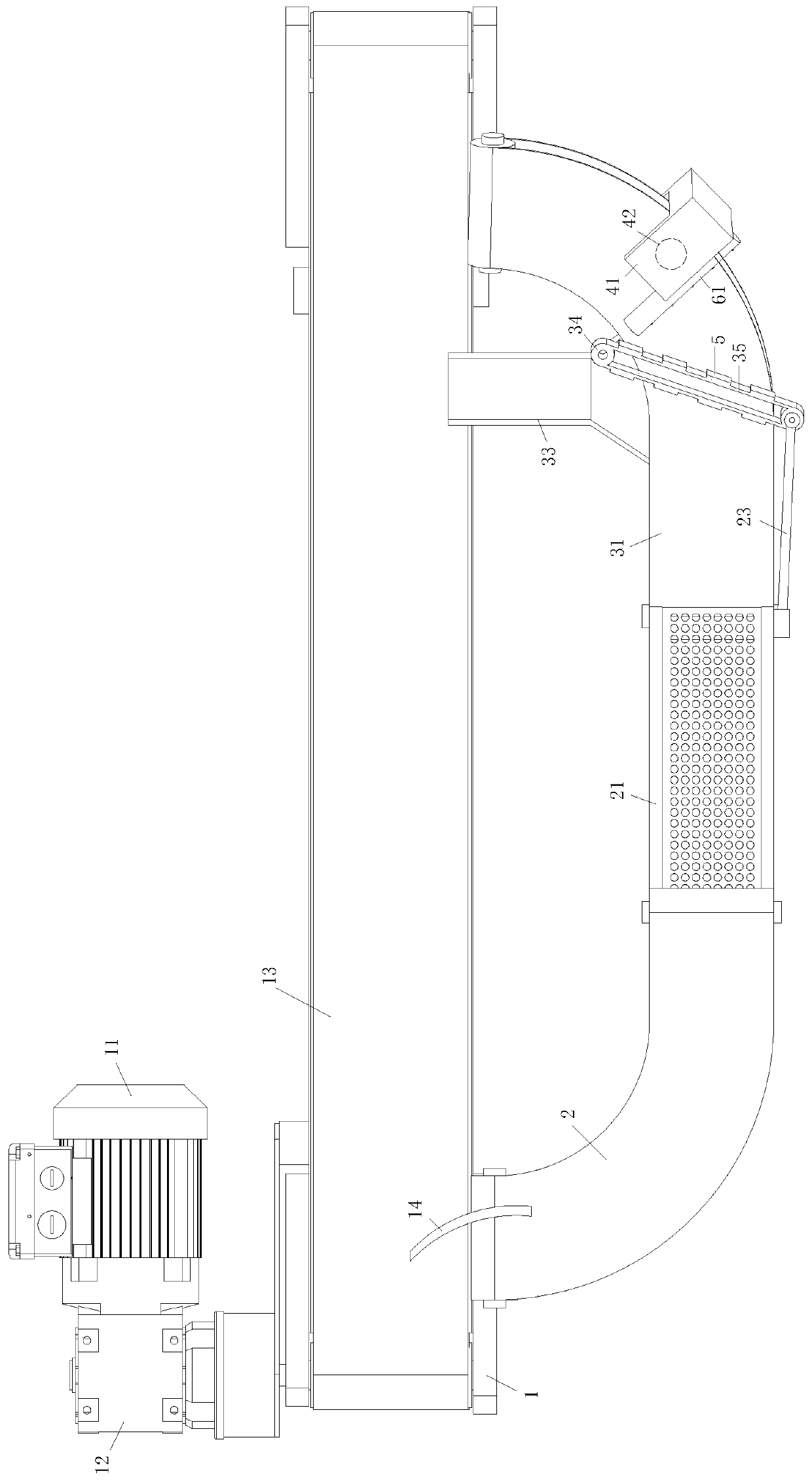

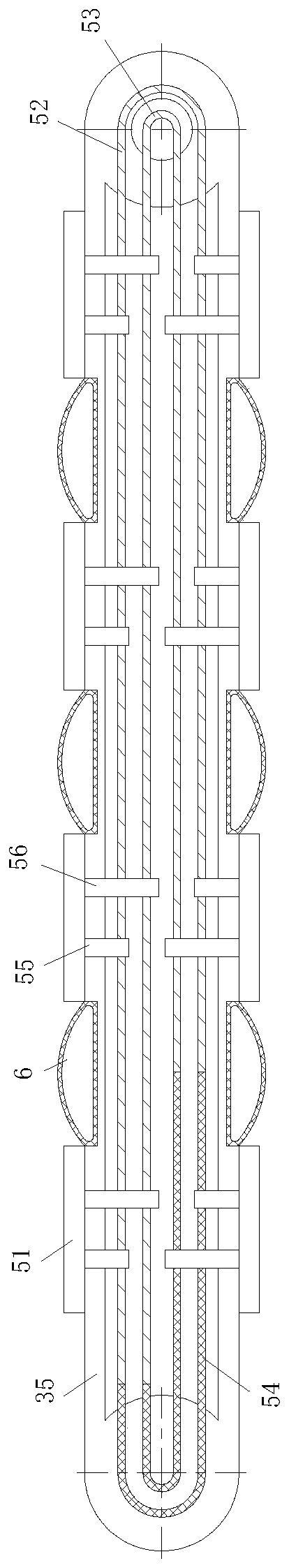

[0022] As an embodiment of the present invention, one end of the scraper 32 close to the No. 1 conveyor belt 13 is hinged to a bracket fixed on the frame 1, and a torsion spring is provided at the hinge between the scraper 32 and the bracket; A screen 21 is provided between the conveyor belt 2 and the No. 3 conveyor belt 31; the side of the screen 21 away from the No. 1 conveyor belt 13 is provided with a revolving pin 22, and a connecting rod 23 is rotatably connected to the revolving pin 22; The other end of the connecting rod 23 is hinged to the end of the scraper 32 away from the backflow tank 33; the rotation of the scraper 32 drives the screen 21 to vibrate, sieves out impurities in the grain, and further improves the detection accuracy of the microwave-type intelligent grain moisture detector; The plate 32 swings continuously under the action of the grain and the torsion spring when scraping off the excess grain. The swinging scraper 32 drives the screen 21 to shake cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com