Method for manufacturing local-thick-copper circuit board and local-thick-copper circuit board

A technology of local thick copper and production method, applied in the production of local thick copper circuit boards and the field of local thick copper circuit boards, can solve the problems of prone to film lamination, high cost, over-corrosion, etc., so as to avoid film lamination and maintain thickness. Consistency, avoid over-corrosion or under-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

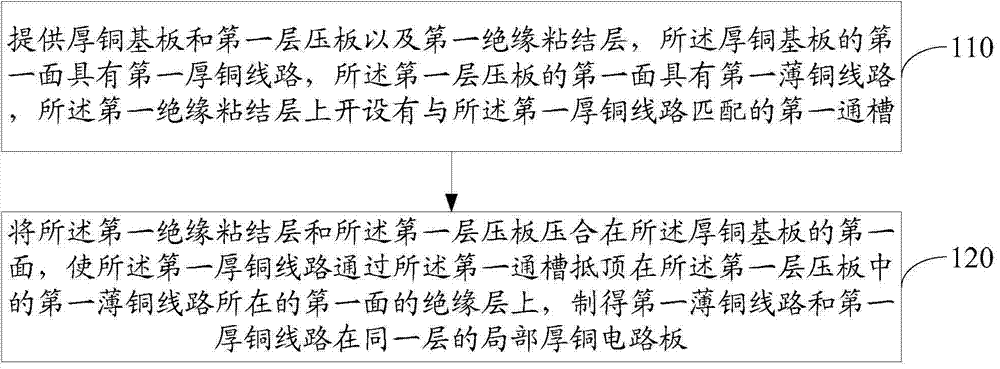

[0031] Please refer to figure 1 , an embodiment of the present invention provides a method for manufacturing a local thick copper circuit board, which may include:

[0032] 110. Provide a thick copper substrate, a first laminate and a first insulating bonding layer, the first surface of the thick copper substrate has a first thick copper circuit, and the first surface of the first laminate has a first thin copper For wiring, a first through-groove matching the first thick copper wiring is opened on the first insulating adhesive layer.

[0033] For thick copper lines and thin copper lines belonging to the same layer but with different thicknesses in the design scheme, the existing technology is to use the process of partial electroplating thickening or local etching thinning on the same metal layer of the copper clad laminate, but it is inevitable There will be problems such as film trapping, over-corrosion or under-corrosion.

[0034] In the embodiment of the present inventi...

Embodiment 2

[0066] Please refer to Figure 7 , an embodiment of the present invention provides a method for manufacturing a local thick copper circuit board, which may include:

[0067] 710. Provide a thick copper substrate, an insulating adhesive layer and a metal layer, one side of the thick copper substrate has a thick copper circuit, and the insulating adhesive layer and the metal layer have slots matching the thick copper circuit.

[0068] In this embodiment, a thick copper substrate with corresponding copper thickness is provided according to the thickness of the thick copper circuit to be formed; a metal layer with a corresponding thickness is provided according to the thickness of the thin copper circuit to be formed; according to the thickness of the thick copper circuit and the thin copper circuit, The difference in thickness provides an insulating bonding layer of corresponding thickness. Generally, the thickness of thick copper lines can be above 5OZ or 8OZ; the thickness of ...

Embodiment 3

[0109] Please refer to Figure 10 , an embodiment of the present invention provides a method for manufacturing a local thick copper circuit board, which may include:

[0110] 1010. Etch the first surface of the metal layer, wherein the non-circuit pattern part of the thick copper circuit area and the thin copper circuit area are etched to reduce the thickness.

[0111] In the embodiment of the present invention, thick copper lines and thin copper lines are fabricated on the metal layer by performing double-sided etching on the metal layer. Said metal layer can specifically be thicker copper foil layer or copper plate, etc., and its thickness can be more than 0.35 mm, or more than 10 OZ (ounce, 1 ounce is about 35 microns). In this embodiment, assuming that the thicknesses of the thick copper circuit and the thin copper circuit are required to be 10OZ and 5OZ respectively, then a metal layer of the same thickness can be blanked according to the size of the required thick coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com