Automatic glue spraying device for shaped charge liner of perforating charge

A kind of ammunition and automatic technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems of non-coincidence of the symmetrical axis of the drug cover, affecting the penetration performance of the perforating bullet, and increasing the production cost, so as to ensure the glue Consistent thickness, simple and controllable process, and consistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In view of this, the core of the present invention is to provide an automatic glue spraying device for the perforating ammunition cover to achieve the purpose of reducing the scrap rate of perforating charges.

[0024] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

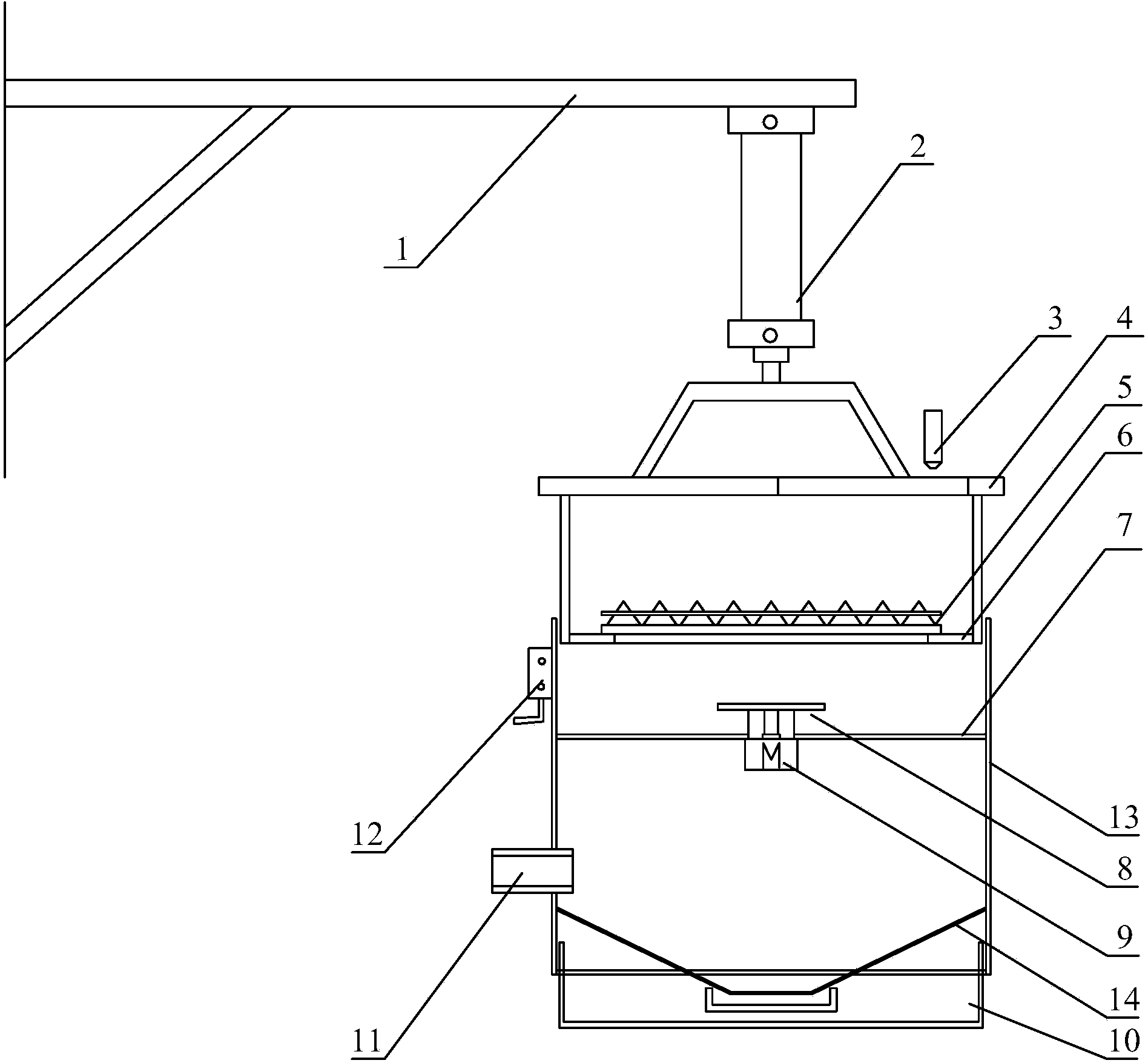

[0025] Such as figure 1 As shown, the perforating ammunition type cover automatic glue spraying device includes:

[0026] Housing 13, housing 13 inside is provided with support 7, and support 7 is provided with rotating platform 8, and rotating platform 8 is driven and rotated by the motor 9 that its fixed end is fixed on the support 7;

[0027] The cover plate 4 that is arranged at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com