PVC (Polyvinyl Chloride) sheet coated with ASA (Acrylonitile Styrene Acrylate) film and film coating method

A sheet and film-coating technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of uneven distribution of film covering, low energy consumption, and low service life, so as to achieve environmental protection and improve service life , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

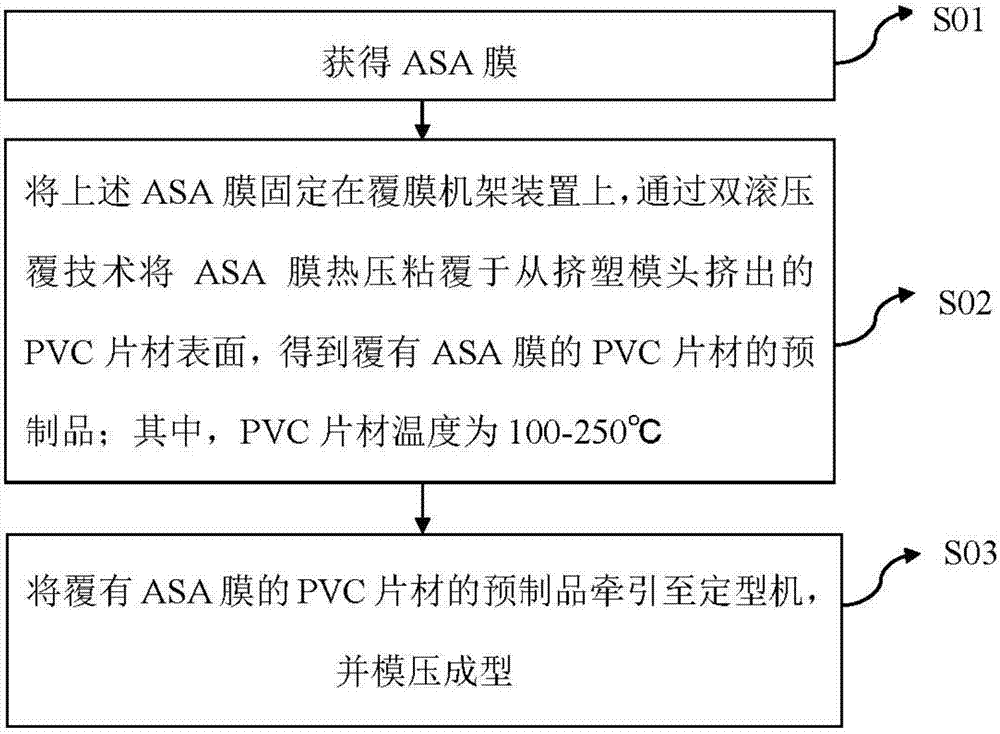

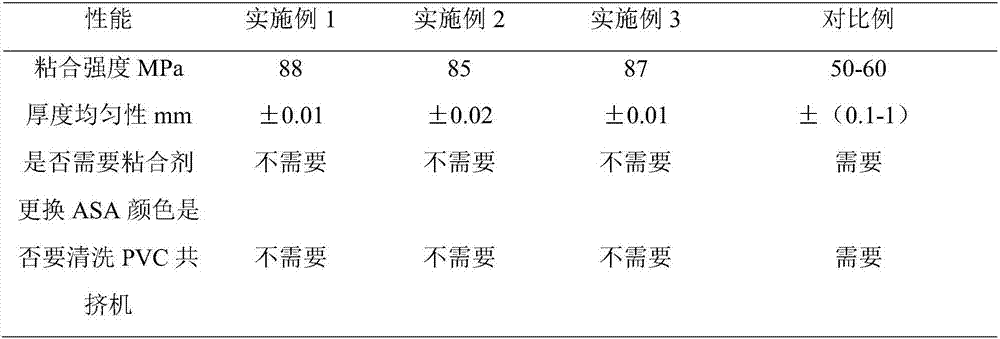

[0034] A weather-resistant ASA coating method for PVC plastic tiles, comprising the steps of:

[0035] S11: Obtain a weather-resistant ASA film.

[0036] The process is: the ASA raw material is extruded through an extruder, cast, and double-rolled to shape it, with a thickness of 3mm.

[0037] S12: Fix the weather-resistant ASA film on the film-coating frame device, and hot-press and bond the weather-resistant ASA film to the surface of the PVC plastic tile extruded from the extrusion die through the double-rolling technology to obtain a covered Preform of PVC sheet of weather resistant ASA film.

[0038] The PVC plastic tile sheet has just been extruded from the extruder 80-type conical twin-screw machine, and the sheet temperature is 250°C.

[0039] S13: Pull the above-mentioned preform of the PVC plastic tile material covered with the weather-resistant ASA film to a setting machine, and mold it into shape. The process utilizes double rollers to pull PVC plastic tiles coate...

Embodiment 2

[0041] A weather-resistant ASA coating method for PVC plastic tiles, comprising the steps of:

[0042] S21: Obtain a weather-resistant ASA film.

[0043] The process is: the ASA raw material is extruded through an extruder, cast, and double-rolled to shape it, with a thickness of 1mm.

[0044] S22: The weather-resistant ASA film is fixed on the film-coated frame device, and the weather-resistant ASA film is hot-pressed and bonded to the surface of the PVC plastic tile extruded from the extrusion die through the double-rolling coating technology, and the coated plastic tile is obtained. Preform of PVC sheet of weather resistant ASA film.

[0045] The PVC plastic tile sheet has just been extruded from a 65-type flat twin-screw extruder, and the sheet temperature is 200°C.

[0046] S23: pulling the preform of the above-mentioned PVC plastic tile material covered with the weather-resistant ASA film to a setting machine, and molding it. The process utilizes double rollers to pul...

Embodiment 3

[0048] A weather-resistant ASA coating method for PVC plastic tiles, comprising the steps of:

[0049] S31: Obtain a weather-resistant ASA film.

[0050] The process is: the ASA raw material is extruded through an extruder, cast, and double-rolled to shape it, with a thickness of 0.05mm.

[0051] S32: The weather-resistant ASA film is fixed on the film-coating frame device, and the weather-resistant ASA film is hot-pressed and bonded to the surface of the PVC plastic tile extruded from the extrusion die through the double-rolling coating technology, and the coated plastic tile is obtained. Preform of PVC sheet of weather resistant ASA film.

[0052] The PVC plastic tile sheet has just been extruded from a 65-type flat twin-screw extruder, and the sheet temperature is 100°C.

[0053] S33: pulling the preform of the above-mentioned PVC plastic tile material covered with the weather-resistant ASA film to a setting machine, and molding it. The process utilizes double rollers to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com