Formation method of soft package lithium ion battery

A lithium ion battery and a technology of a chemical formation method, which are applied in the field of lithium ion battery manufacturing to achieve the effects of low chemical energy consumption, improved performance, tight and consistent spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

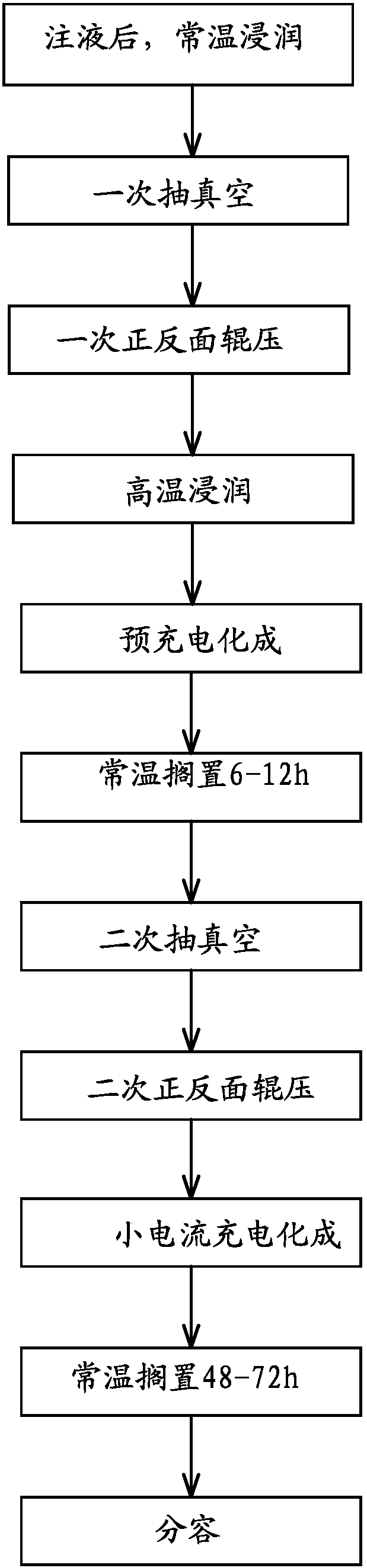

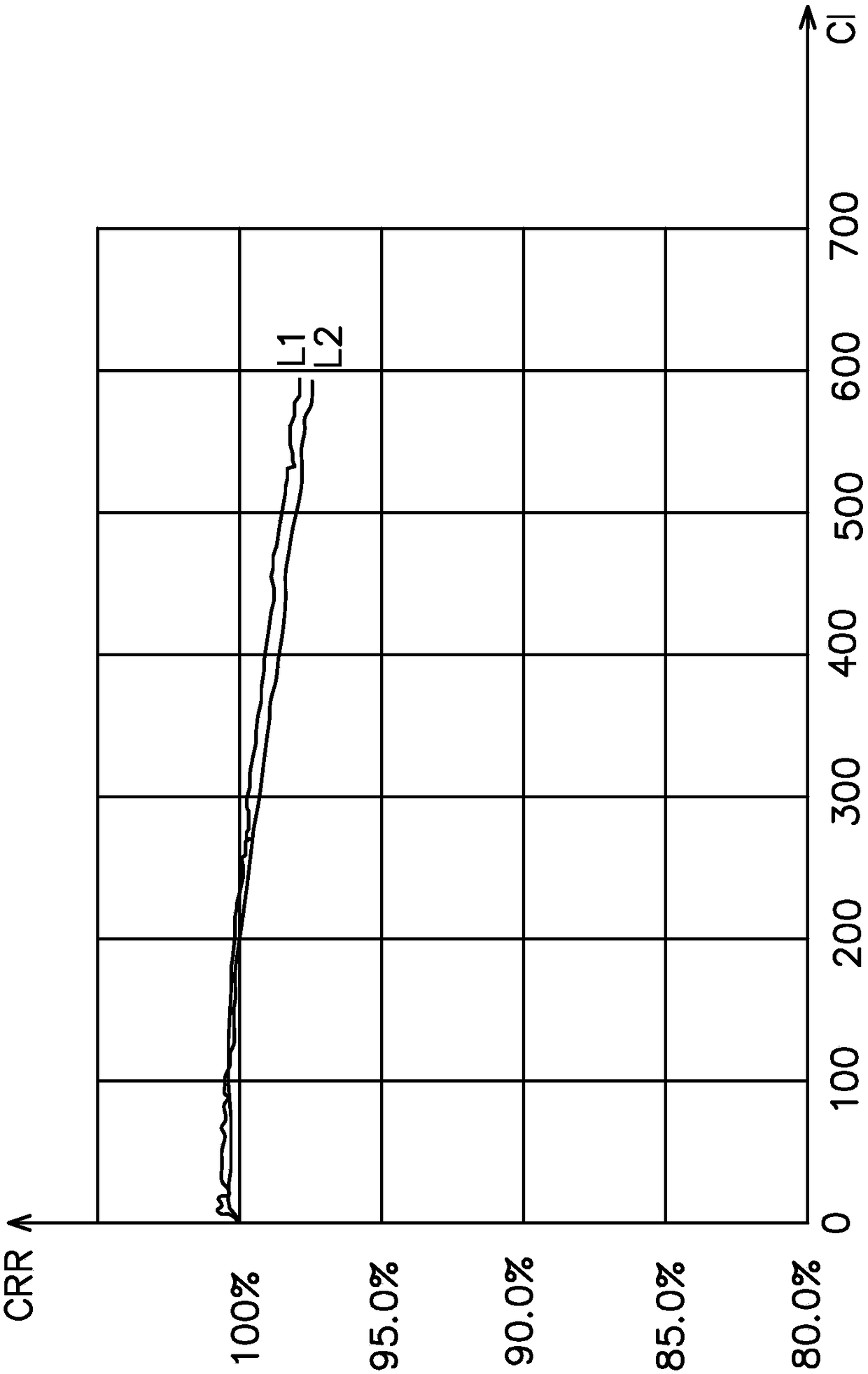

[0024] Such as figure 1 , 2As shown, the lithium ion battery cathode material of the present application is lithium cobaltate, lithium manganese oxide, lithium iron phosphate, lithium nickelate, lithium manganese phosphate, lithium nickel cobalt manganate and / or lithium nickel cobalt aluminate, lithium ion battery negative electrode The material is artificial graphite, natural graphite, composite graphite, silicon-based negative electrode and / or lithium titanate. The formation method of the soft-pack lithium-ion battery includes step 1, one-time vacuuming: after the lithium-ion battery is injected, the airbag is inclined upward at 45°, and soaked at room temperature for 6-12 hours, and more preferably, the soaking time at room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com