Ultrahigh molecular weight polyethylene plate production method

An ultra-high molecular weight polyethylene board technology, used in applications, household appliances, flat products, etc., can solve the problems of cloud spots, entangled molecular chains of ultra-high molecular weight polyethylene, poor fluidity, uneven thickness of the board, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The production method of ultra-high molecular weight polyethylene board in this embodiment, the specific pressing steps are: add ultra-high molecular weight polyethylene particles, carbon fiber, and silicone resin The mixture of vinyl powder is fed into the molding machine. In the mixture, ultra-high molecular weight polyethylene powder is ultra-high molecular weight polyethylene powder with a molecular weight greater than 3 million; the content of ultra-high molecular weight polyethylene powder is 85-94%; the content of carbon fibers of 0.1 to 5 mm is 5-10%; The content of silicone resin is 1-5%.

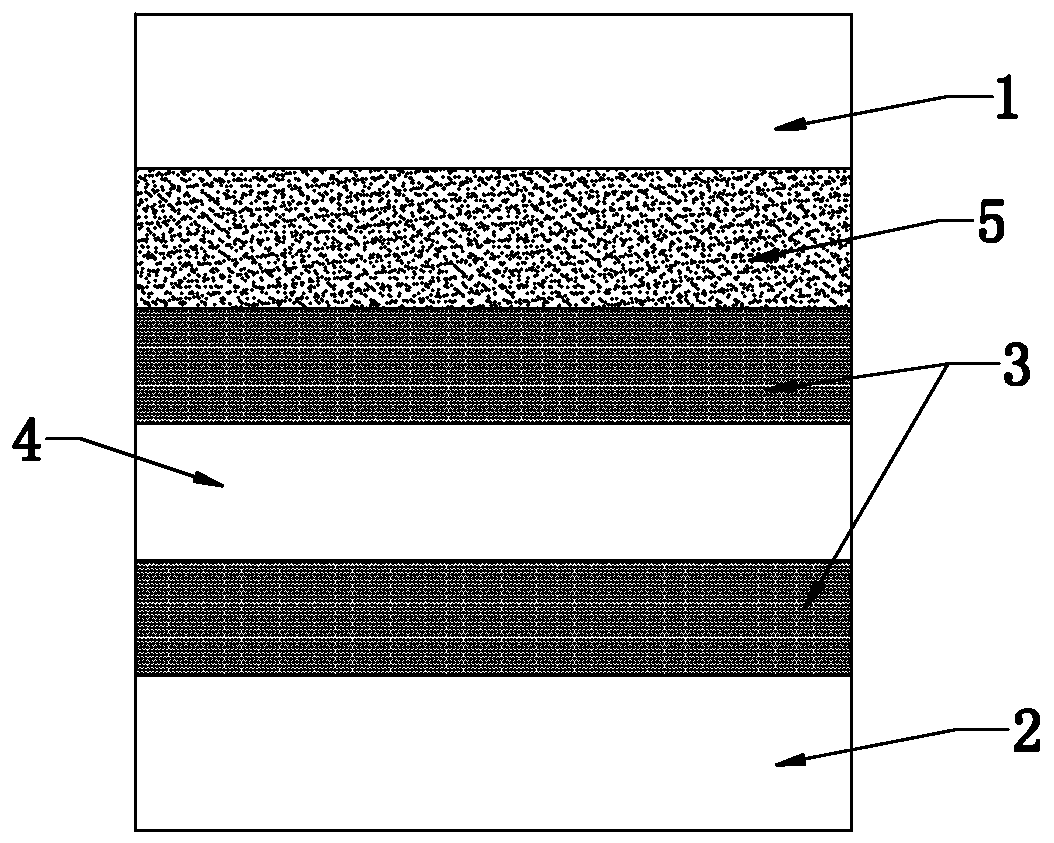

[0016] In this embodiment, 94 kg of ultra-high molecular weight polyethylene particles with a molecular weight greater than 3 million, 5 kg of carbon fiber, and 1 kg of silicone resin are mixed in the mixer. Two metal plates 3 are placed between the upper mold gland 1 and the lower mold gland 2 of the molding machine, the material is P20 material, and polished and chrome-pl...

Embodiment 2

[0019] The production method of ultra-high molecular weight polyethylene board in this embodiment, the specific pressing steps are: add ultra-high molecular weight polyethylene particles, carbon fiber, and silicone resin The mixture of vinyl powder is fed into the molding machine. In the mixture, ultra-high molecular weight polyethylene powder is ultra-high molecular weight polyethylene powder with a molecular weight greater than 4.5 million; the content of ultra-high molecular weight polyethylene powder is 85-94%; the content of carbon fibers of 0.1 to 5 mm is 5-10%; The content of silicone resin is 1-5%.

[0020] In this embodiment, 90 kg of ultra-high molecular weight polyethylene particles with a molecular weight greater than 4.5 million, 8 kg of carbon fiber, and 2 kg of silicone resin are mixed in the mixer. Two metal plates 3 are arranged between the upper die gland and the lower die gland of the molding machine, said metal plates are preferably iron plates, the two ir...

Embodiment 3

[0023] The production method of ultra-high molecular weight polyethylene board in this embodiment, the specific pressing steps are: add ultra-high molecular weight polyethylene particles, carbon fiber, and silicone resin The mixture of vinyl powder is fed into the molding machine. In the mixture, the ultra-high molecular weight polyethylene powder is ultra-high molecular weight polyethylene powder with a molecular weight greater than 6 million; the content of ultra-high molecular weight polyethylene powder is 85-94%; the content of 0.1-5mm carbon fiber is 5-10%; The content of silicone resin is 1-5%.

[0024] In this embodiment, 85 kg of ultra-high molecular weight polyethylene particles with a molecular weight greater than 6 million, 10 kg of carbon fiber, and 5 kg of silicone resin for mixing in the mixer are placed between the upper mold gland and the lower mold gland of the molding machine. Two metal plates 3, said metal plates are preferably iron plates, the two iron pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com