Graphite film calendaring machine

A graphite film and equipment technology, which is applied in the field of graphite film rolling equipment, can solve problems such as damage and achieve the effect of improving the stability of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

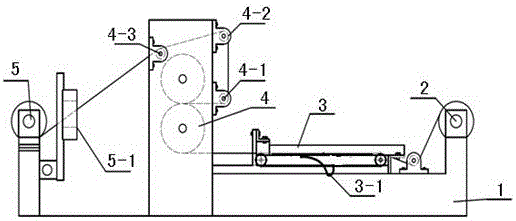

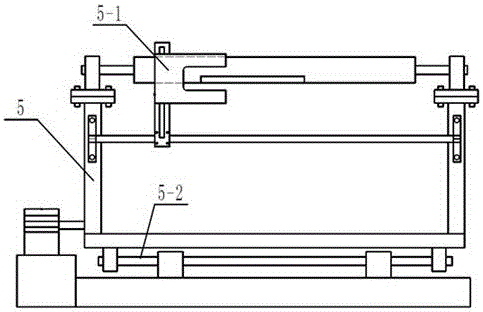

[0012] Depend on figure 1 , figure 2 Known, a kind of graphite film calendering equipment of the present invention is made up of main support 1, conveying film roller assembly 2, conveyer belt assembly 3, power roller assembly 4, recovery roller assembly 5, and conveying film roller assembly 2 is installed on the top of main support 1 At the rightmost position, the conveyor belt assembly 3 is installed above the main support 1 and on the left side of the conveying film roller assembly 2, the upper surface of the conveyor belt assembly 3 is lower than the lower surface of the conveying film roller assembly 2, and the power roller assembly 4 is installed on the main support 1 above and on the left side of the conveyor belt assembly 3, the recovery roller assembly 5 is installed and fixed on the leftmost side above the main support 1, and the air suction assembly 3-1 is arranged below the conveyor belt assembly 3, through which the air suction assembly 3 -1 The graphite film ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com