Membrane rolling roller

A technology for winding rollers and diaphragms, applied in the field of diaphragm winding rollers, can solve problems such as diaphragm release, and achieve the effect of ensuring thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

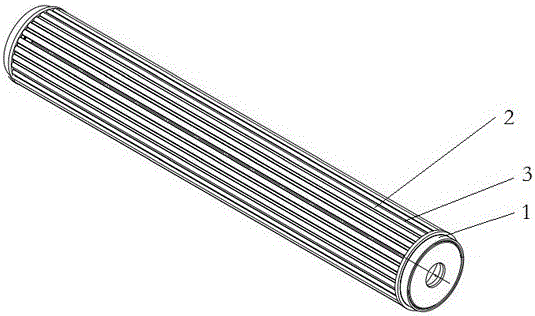

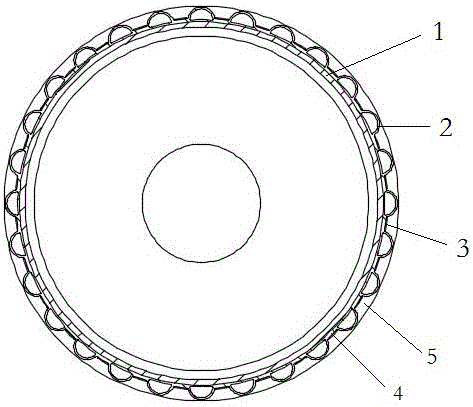

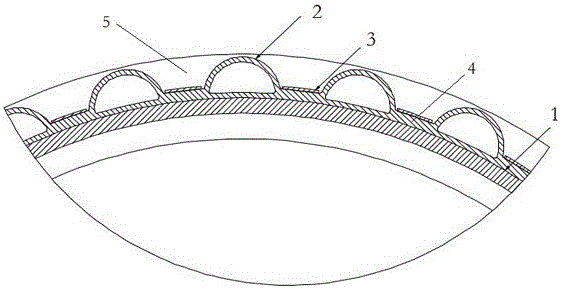

[0019] The specific embodiment of diaphragm winding roller of the present invention, as Figure 1 to Figure 3 As shown, the diaphragm winding roller includes a cylinder body 1, on which a plurality of airbags 2 distributed at intervals are arranged, the airbags 2 are made of rubber with a Shore hardness of 20-30, and have certain flexibility; the airbags 2 is parallel to the axial direction of the cylinder 1, extends to both axial ends of the cylinder 1, and is evenly spaced along the circumference of the cylinder axis.

[0020] The airbag 2 has a D-shaped cross section in the direction perpendicular to the axis of the cylinder, the D-shaped flat side fits the cylinder, the inner cavity of the airbag is filled with air, and the outer surface of the airbag constitutes the outer peripheral surface for winding the diaphragm, that is, the outer surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com