Packaging structure of SAW filter and manufacturing method thereof

A packaging structure and filter technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of high cost of surface sealing cover, fluctuation of filter performance, increase of packaging volume, etc., and achieve reliable packaging Low reliability, product safety and reliability, solve the effect of large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific drawings and embodiments.

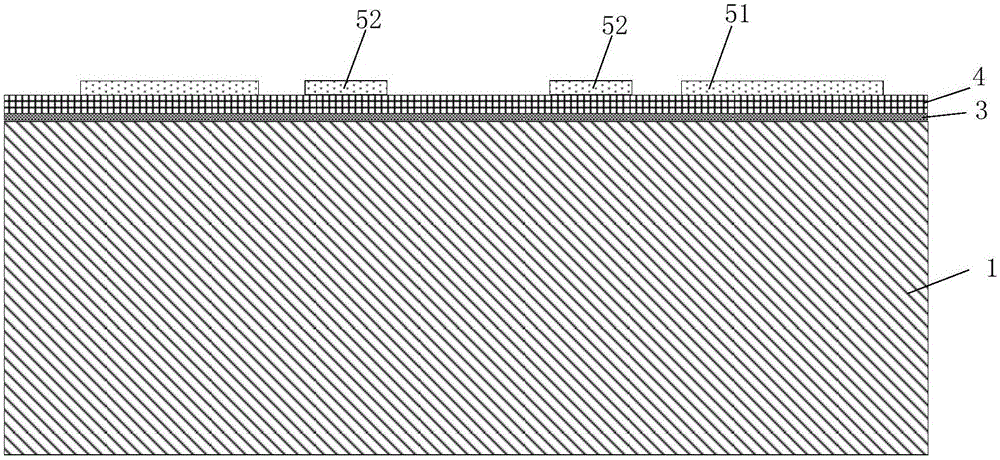

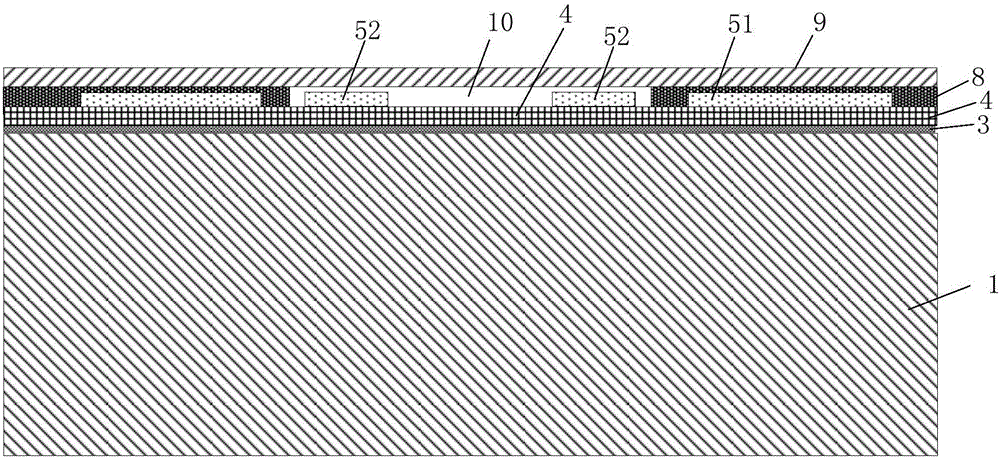

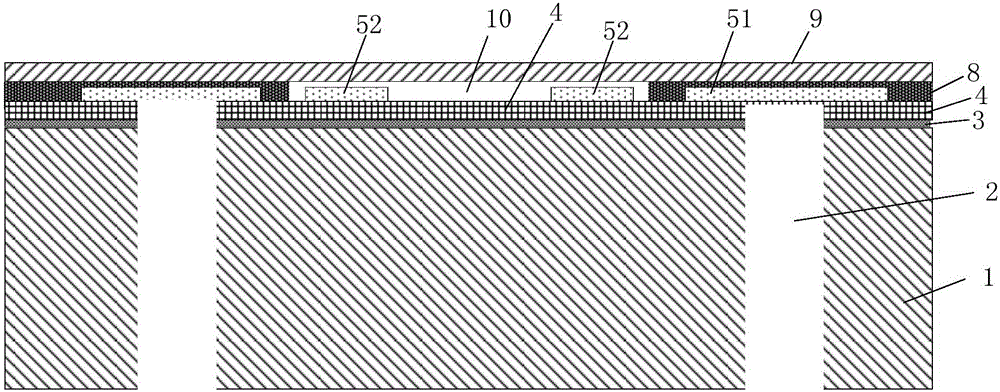

[0035] The packaging structure of the SAW filter, such as Figure 5 As shown, a substrate 1 is included, and a through hole 2 connecting the front and back of the substrate is provided in the substrate 1, and an insulating layer 3 is covered on the front surface, the back surface of the substrate 1, and the inner surface of the through hole 2;

[0036] A through hole 2 connecting the front and back of the base is provided in the base 1, and an insulating layer 3 is covered on the front surface, the back surface of the base 1, and the side walls of the through hole 2;

[0037] A layer of piezoelectric material 4 is covered on the insulating layer 3 on the front side of the base body 1; the front side lead-out electrode 51 and the back side lead-out electrode 6 are respectively provided on the front side and back side of the base body 1 corresponding to the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com