Stacking equipment capable of simultaneously taking and placing logistics boxes on multiple stations

A technology of logistics boxes and equipment, which is applied in the stacking of objects, de-stacking, transportation and packaging of objects, etc., can solve the problems of low efficiency and incompatibility with the management requirements of large-scale three-dimensional warehouses, and achieve the effect of improving the efficiency of picking and placing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below, the present invention will be described in detail with reference to the accompanying drawings.

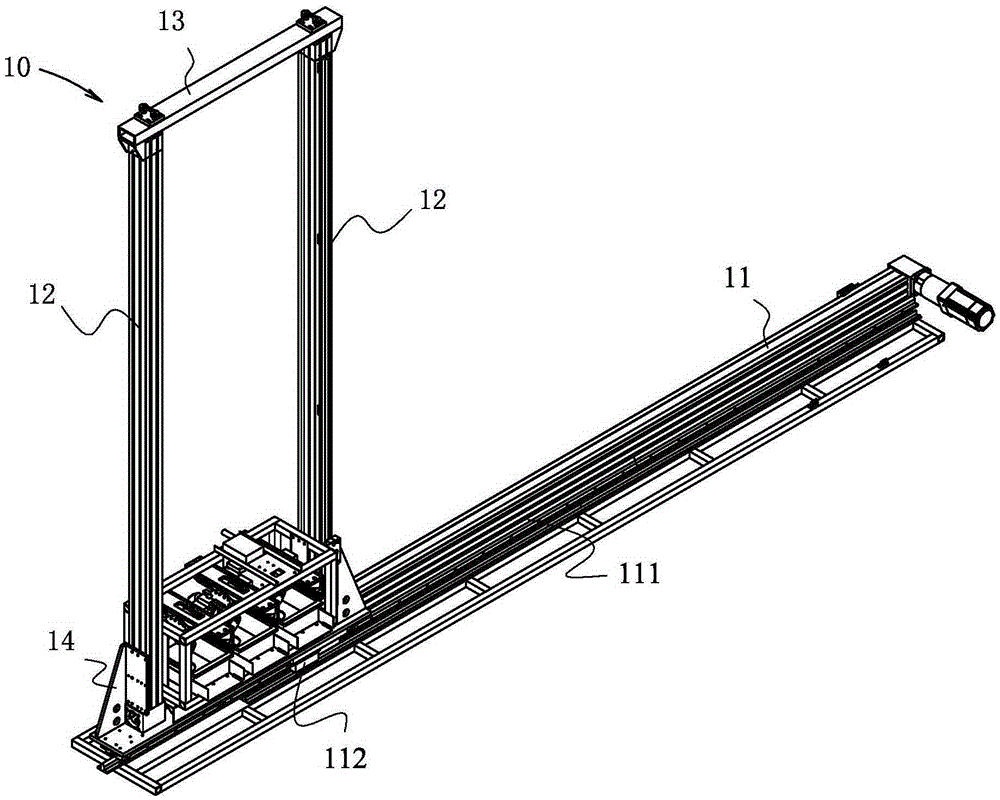

[0016] like figure 1 , figure 2 As shown, this embodiment provides a palletizing device capable of taking and placing logistics boxes at multiple stations at the same time. , and the palletizer 10 can slide vertically and horizontally on the support frame 10 .

[0017] The support frame 10 includes: a horizontal moving track 11 and a vertical moving track 12 , and there are two vertical moving tracks 12 , which are arranged on the horizontal moving track 10 and can slide along the horizontal moving track 10 . The tops of the two vertical motion rails 12 are connected by a crossbeam 13, and the crossbeam 13 and the two vertical motion rails 12 form a stable gantry shape, which can ensure that the equipment runs smoothly without shaking.

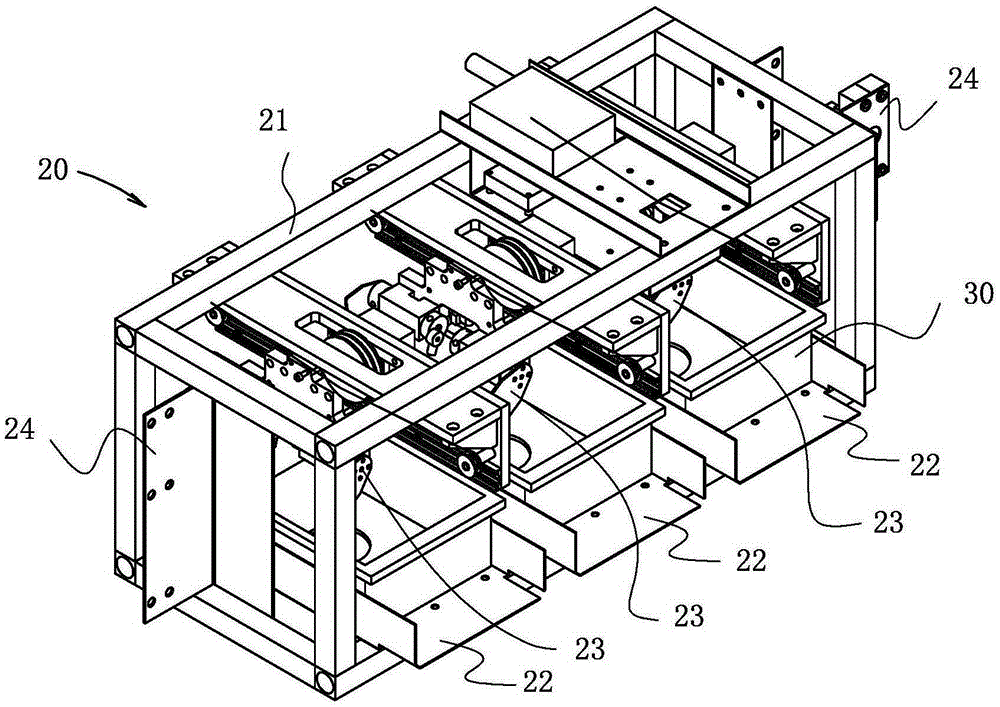

[0018] The palletizer 20 is arranged at the bottom of the vertical movement track 12 and can slide along the horizontal movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com