Flat battery transferring cart

A technology for transferring vehicles and batteries, which is applied in motor vehicles, trolleys, multi-axle trolleys, etc., can solve the problems of high time consumption, low safety performance, and reduce the power exchange efficiency of flat batteries, so as to achieve convenient operation, improve practical performance, Conducive to the effect of power exchange efficiency and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

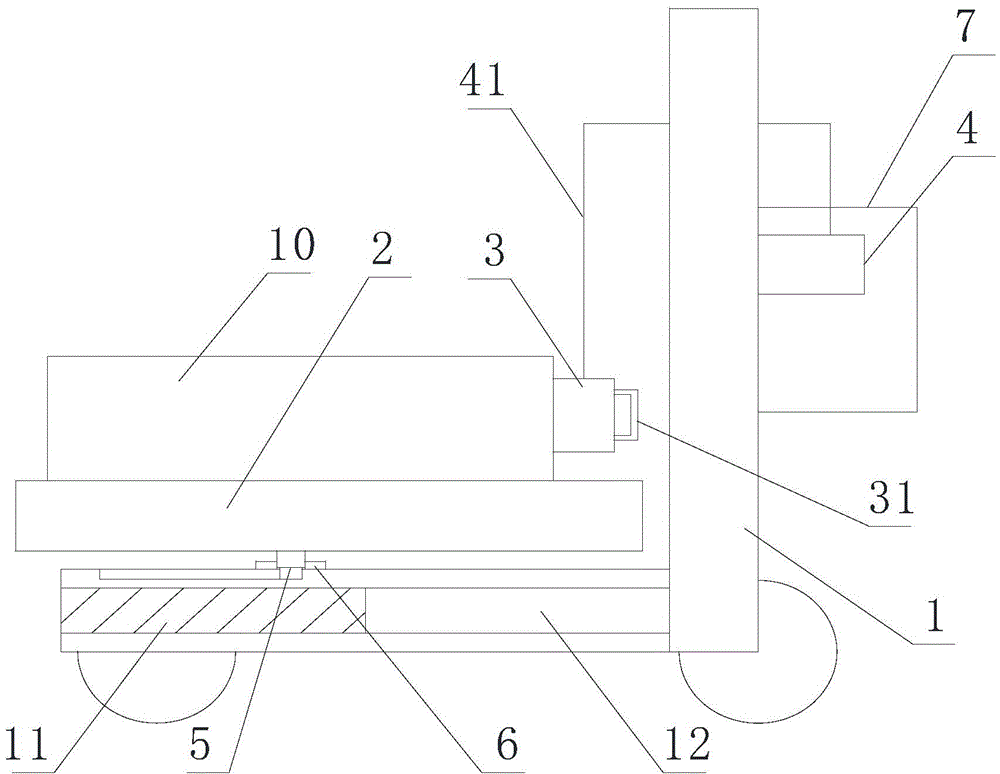

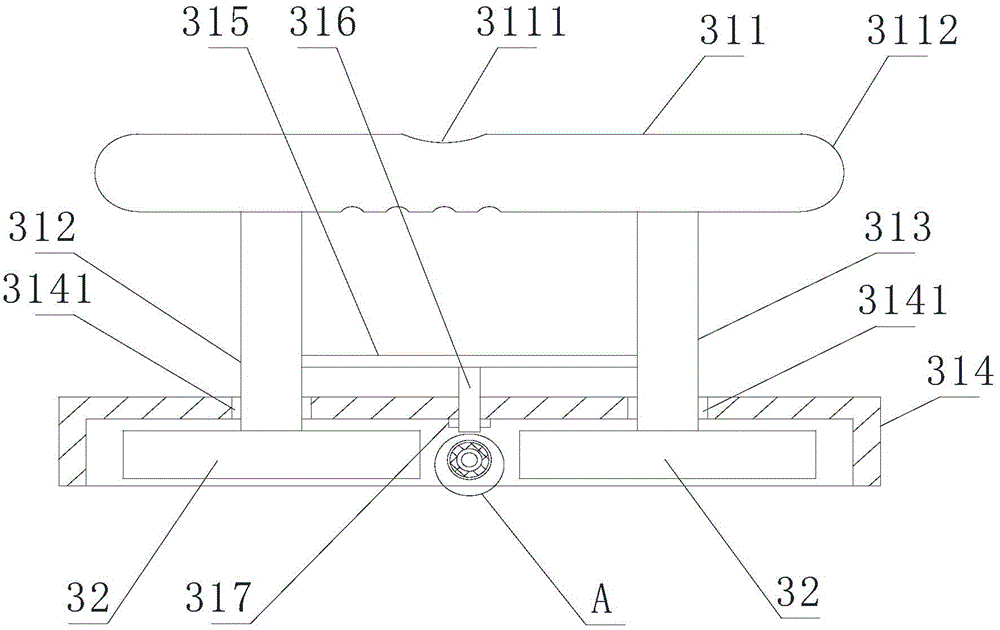

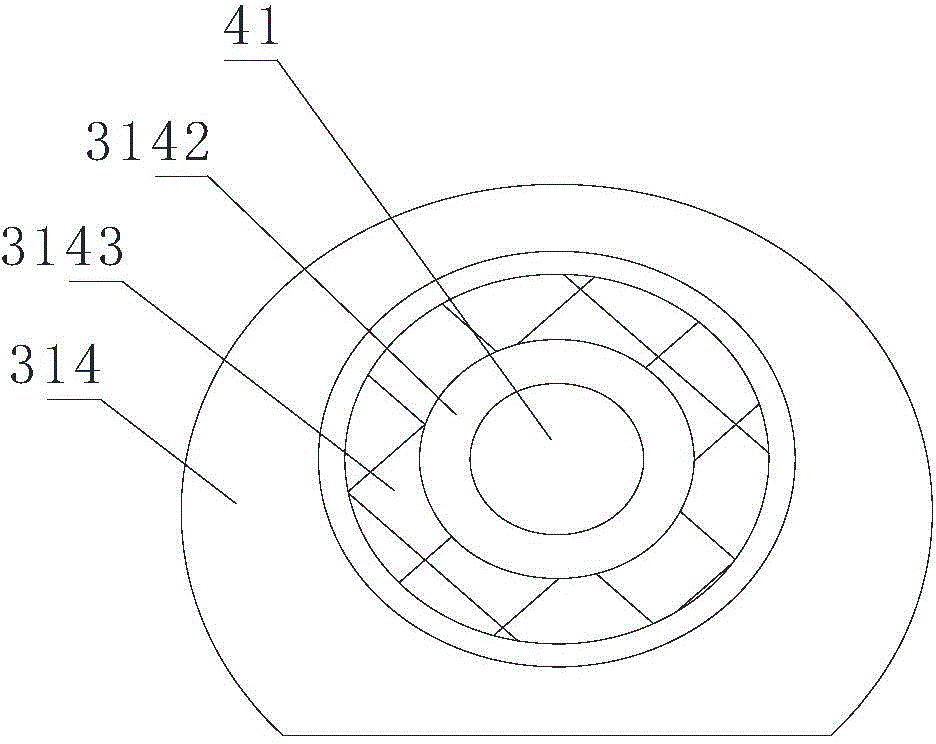

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a flat battery transfer vehicle includes a car body 1, a tray 2, at least one suction cup assembly 3 connected to a flat battery 10, and the suction cup assembly 3 includes a handle 31 that facilitates the operator to extract the flat battery. At least one electromagnetic chuck 32 fixedly connected to the handle 31. The electromagnetic chuck 32 uses a direct current of 12V, a diameter of 8 cm, and generates a suction force of 100 kg. The vehicle body 1 is provided with a control electromagnetic chuck 32 to disconnect or energize The control assembly 4, the tray 2 is provided with a steering assembly 5 that drives the tray 2 to rotate 90° to the right or 90° to the left on the car body 1, and the car body 1 is provided with a steering assembly 5 that restricts The rotating restricting assembly 6, the handle 31 includes a cross bar 311, a first column 312 and a second column 313 fixedly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com