Disk-feeding braider and classified gripping method thereof

A braiding machine and material feeding technology, which is applied in the direction of packaging material feeding device, external support, transportation packaging, etc., can solve the problem of poor packaging quality, single integrated circuit block gripper, no obvious improvement in braiding quality and production efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

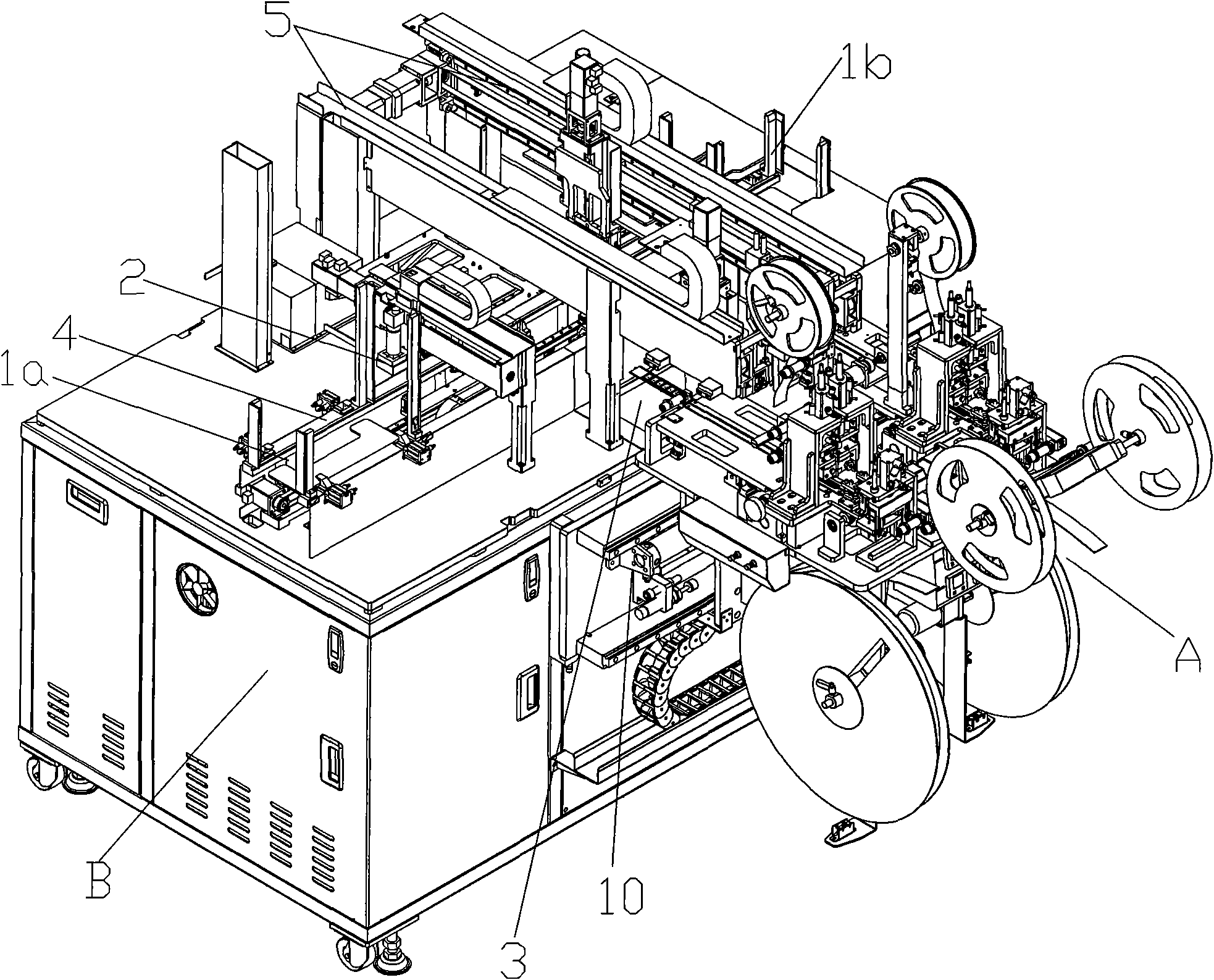

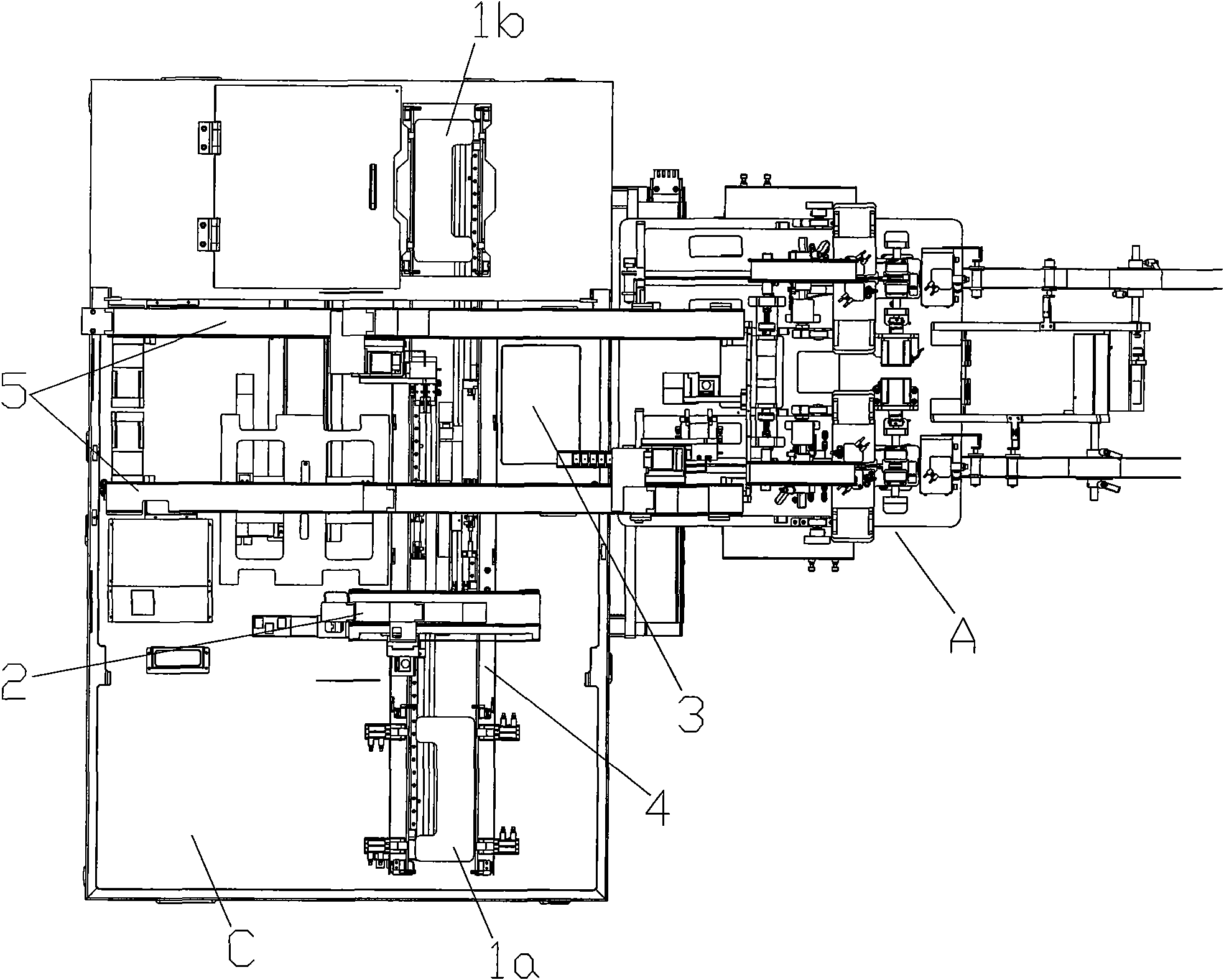

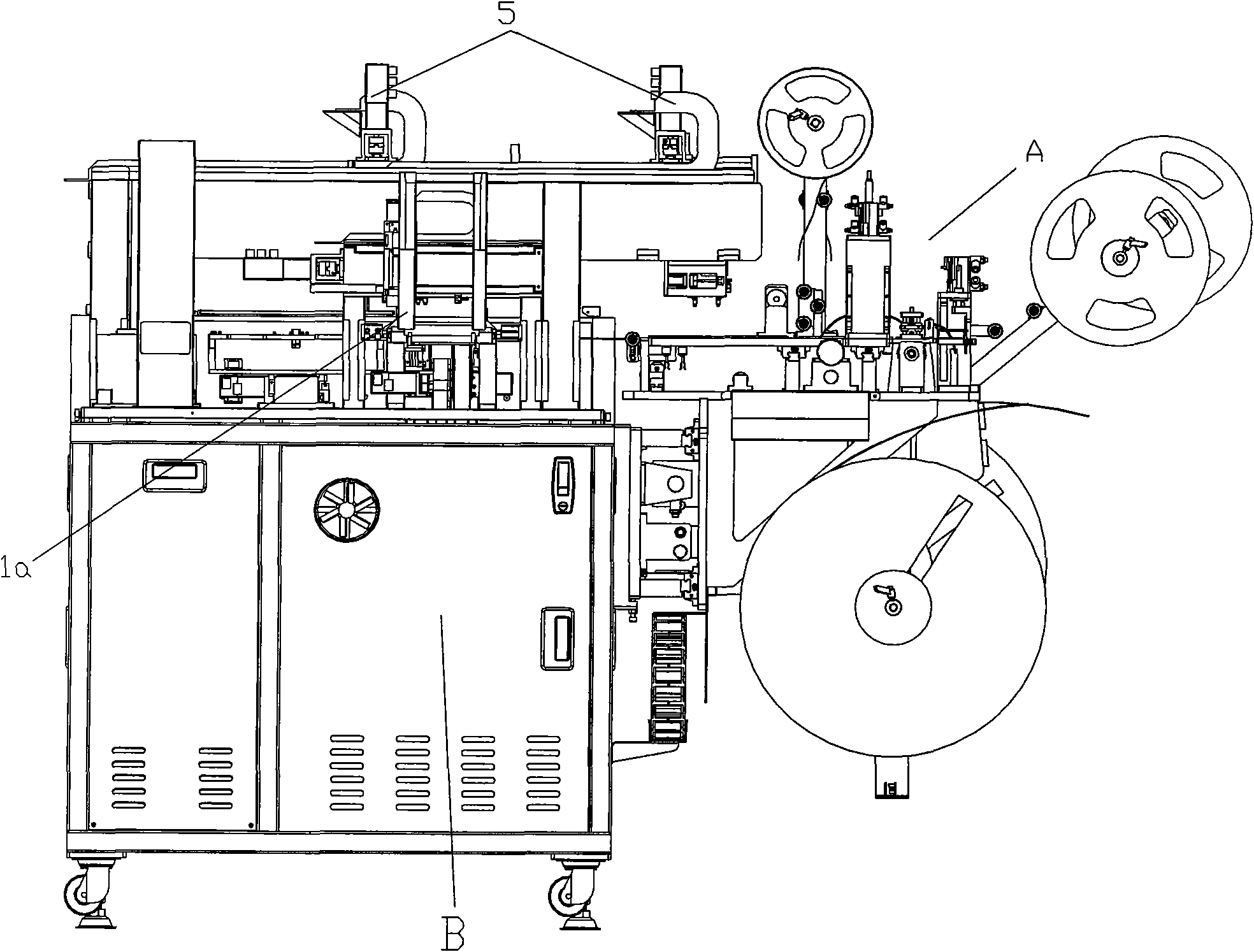

[0081] Below in conjunction with accompanying drawing, the disc feeding braiding machine of the present invention will be further described.

[0082] Such as Figure 1a , 1b , 1c and 1d, the disc feeding braiding machine of the present invention includes a pallet conveying device 4, a pallet separating device 1a, a top surface scanning device 2, a double gripper sorting pick-and-place device 5, a three-dimensional scanning device 3, unqualified Product collecting device 6, empty tray stacking device 1b, and braiding and packaging device A. The electrical control system B is used to control the coordinated action among the above-mentioned devices.

[0083] Such as Figure 2a As shown, the pallet conveying device 4 includes a front support rail 41 a and a rear support rail 41 b installed on the workbench C, and a pallet pushing device 42 . The inner sides of the front and rear support guide rails are provided with tray slideways 411 opposite to each other for supporting trays...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com