Carrying robot, container taking method, container loading method and warehouse logistics system

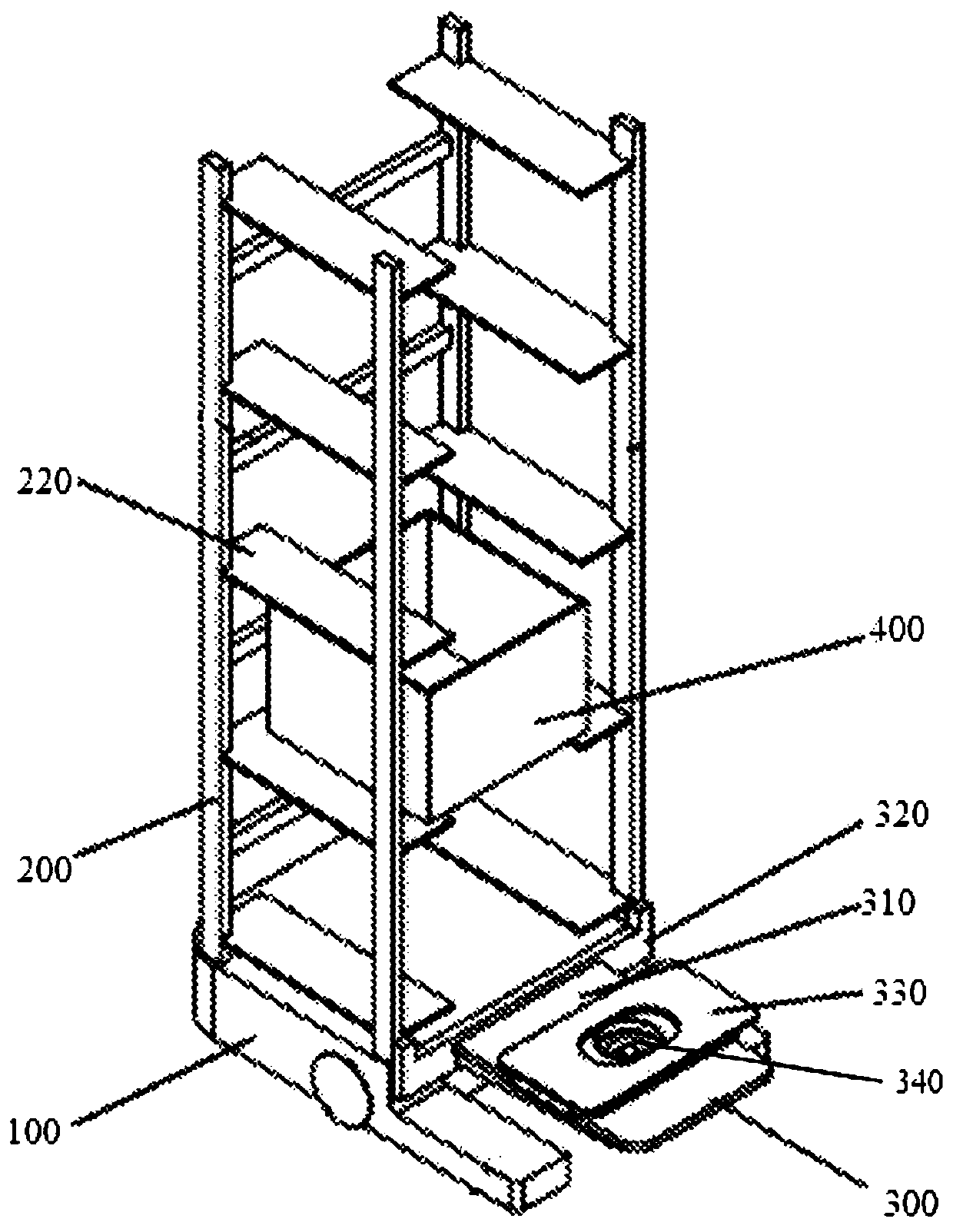

A technology for handling robots and cargo boxes, applied in the field of warehousing and logistics, can solve the problems of difficulty in effectively improving the efficiency of picking and logistics, low picking and placing efficiency of the cargo box 400, and complex structure of the cargo box transmission unit 300, and achieves loading of the cargo box. Convenient and fast operation, improve the efficiency of goods picking and logistics, and improve the efficiency of goods picking and warehousing logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

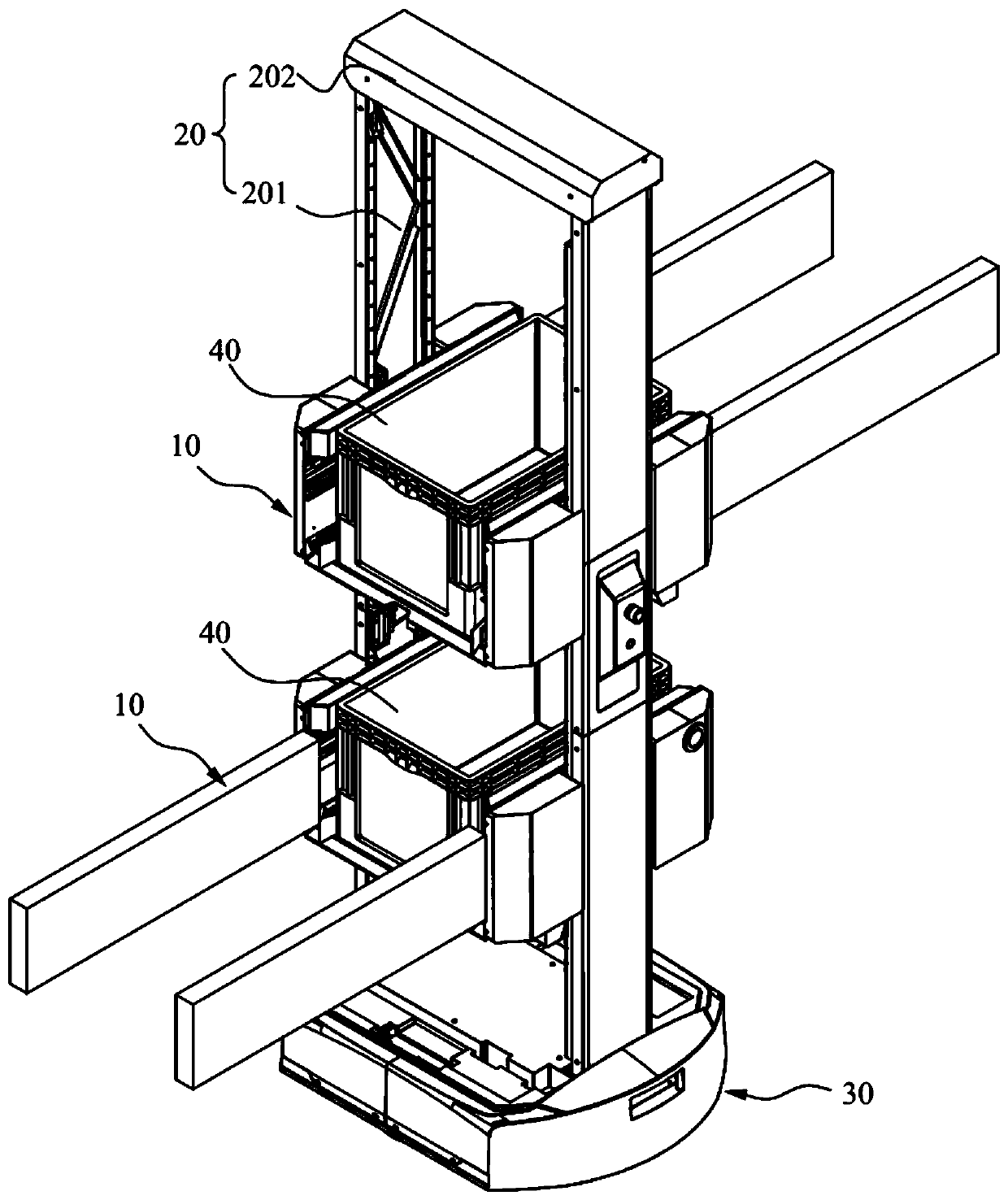

[0073] figure 2 The schematic diagram of the structure of the handling robot provided by the embodiment of the present invention, such as figure 2 As shown, this embodiment provides a handling robot, which is used to carry and pick and place the container 40, which is mainly used in the warehousing and logistics industry to pick, place and transport the container 40 with the order goods or express delivery , to implement order-based pickup or loading operations. It can also be applied to other places where cargo boxes 40 or goods need to be transported. The application of the transport robot in this embodiment is only exemplary, and this embodiment does not specifically limit it.

[0074] Such as figure 2 As shown, the handling robot provided in this embodiment includes a mobile chassis 30, a stand 20, a box picking mechanism 10, a detection component and a controller. Wherein, the mobile chassis 30 is used to realize the movement of the handling robot on the ground, so ...

Embodiment 2

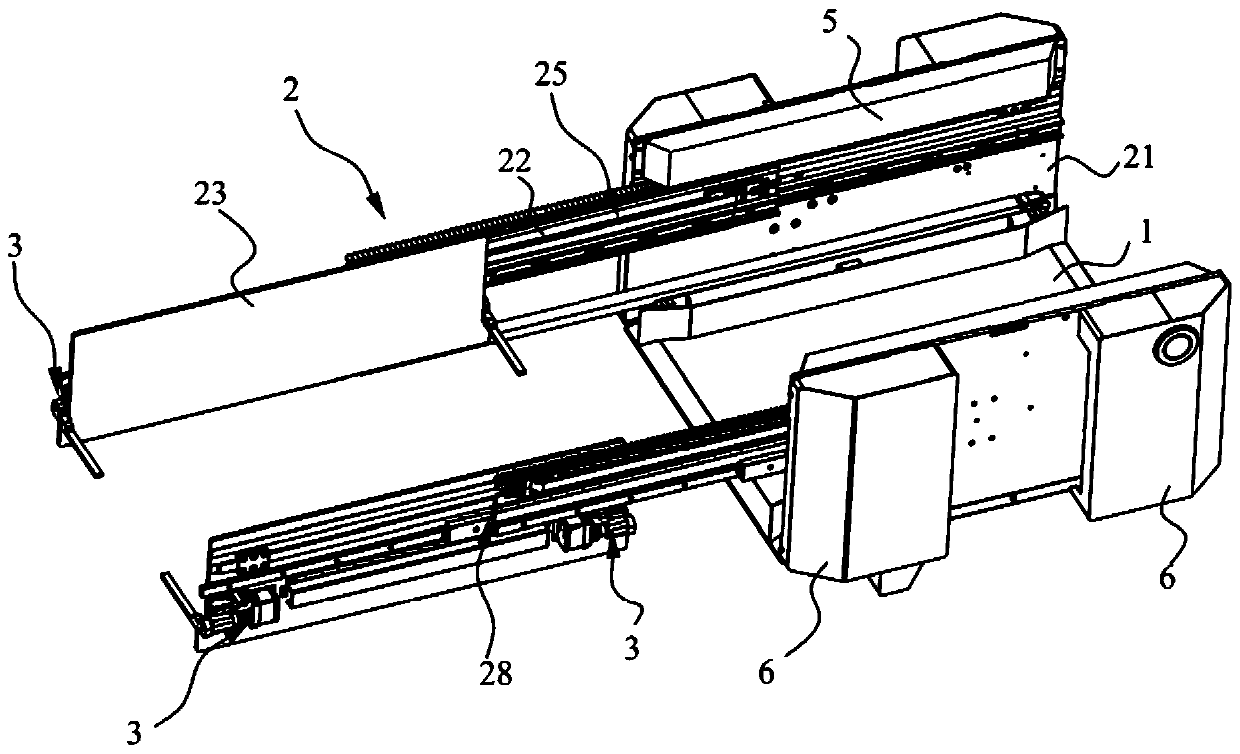

[0119] This embodiment provides a handling robot. Compared with Embodiment 1, the handling robot provided in this embodiment also includes a mobile chassis 30, a stand 20 arranged on the mobile chassis 30, and at least Two box-taking mechanisms 10 and a lifting mechanism that drives the box-taking mechanism 10 to lift vertically relative to the stand 20, each box-taking mechanism 10 includes a telescopic assembly 2, a temporary storage plate 1 and a lever assembly 3. The difference is that the structure of the telescopic assembly 2 provided in this embodiment is different from that of the first embodiment. This embodiment only describes the structure of the telescopic assembly 2 in detail, and does not repeat the same structure as that of the first embodiment.

[0120] Figure 5 It is a structural schematic diagram of the box-taking mechanism 10 provided by the embodiment of the present invention, Image 6 It is a structural schematic diagram of the box-taking mechanism 10 pr...

Embodiment 3

[0137] Figure 7 The flow chart of the box picking method provided by the embodiment of the present invention, such as Figure 7 As shown, this embodiment provides a box picking method, which uses the handling robot provided in the first embodiment to pick up the target box 40 on the inventory container, so as to realize the order picking task.

[0138] In this embodiment, the height of the inventory container is basically the same as that of the handling robot, so that the handling robot can pick up the cargo box 40 on each layer of the inventory container. And the height of each box-taking mechanism 10 is less than or equal to the height of the cargo box 40, to avoid that when two box-taking mechanisms 10 pick up the cargo boxes 40 on the adjacent two-layer cargo positions respectively, the box-taking mechanism 10 is opposite to the adjacent box-taking mechanism. 10's unboxing operation caused interference.

[0139] Specifically, the box picking method provided in this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com