Sorter pick-and-place device

A pick-and-place device and sorting machine technology, applied in sorting, manipulators, manufacturing tools, etc., can solve the problems of increasing sorting time, unable to increase the speed of pick-and-place arm 13, and unable to improve sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

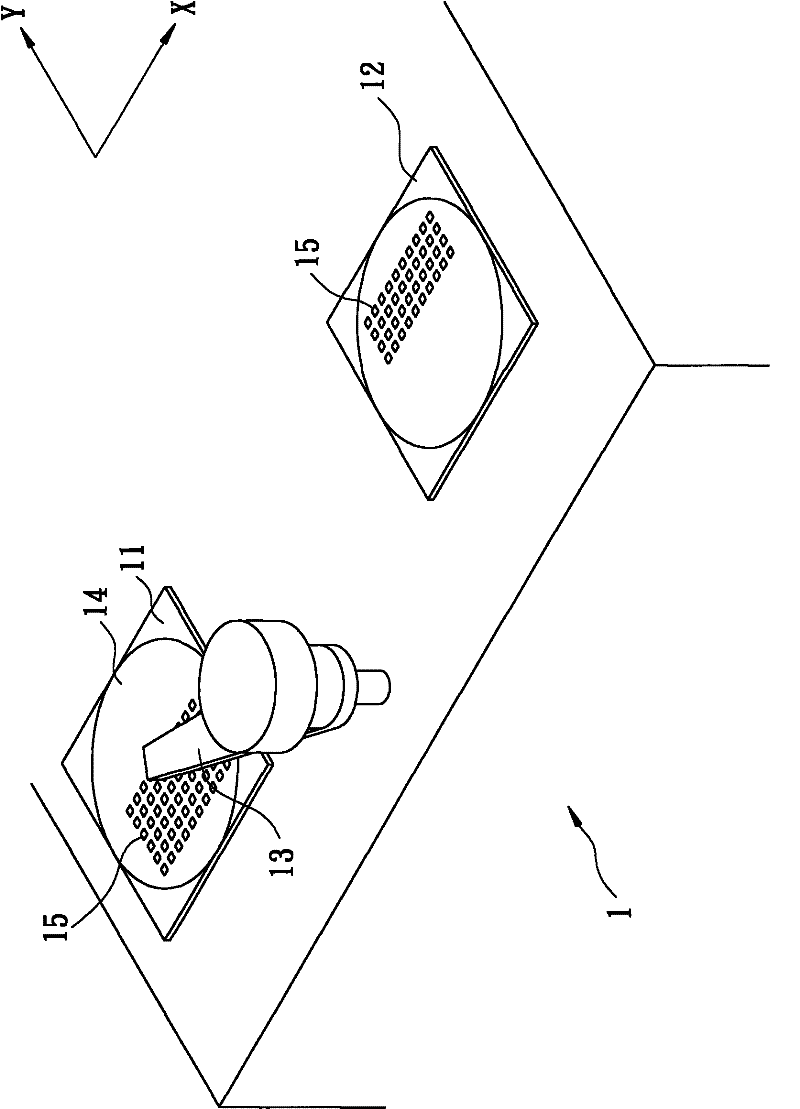

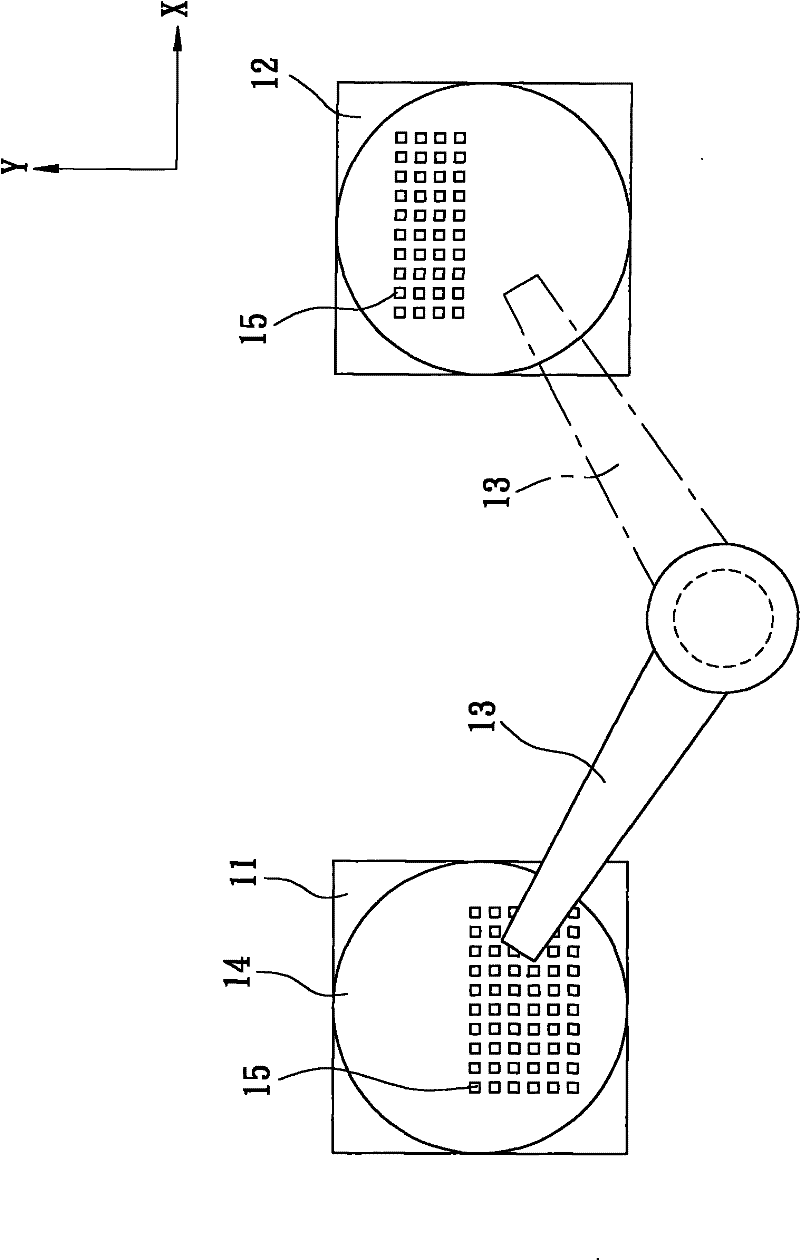

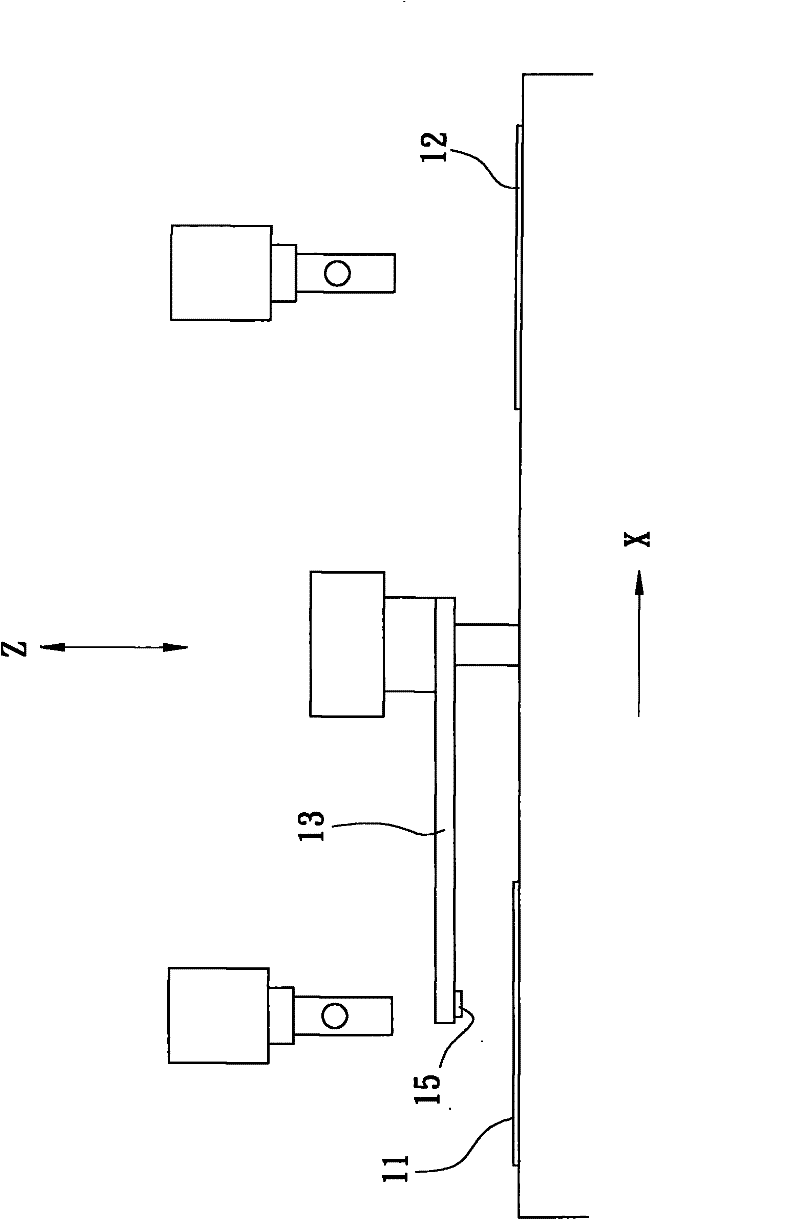

[0024] refer to Figure 4 , Figure 5 and Figure 6 , The first preferred embodiment of the pick-and-place device for the sorter of the present invention includes a tray 2 to be sorted, a tray 3 that has been sorted, and a pick-and-place arm set 4 .

[0025] The tray 2 to be sorted moves on a horizontal plane along a first direction x' and a second direction y', the sorted tray 3 is spaced apart from the tray 2 to be sorted along the first direction x', and the sorted tray 3 Move along the first direction x' and the second direction y'. In this preferred embodiment, the first direction x' and the second direction y' are perpendicular to each other, but it is not limited to this in ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com