Method for improving ship handling efficiency of containers (or bulk cargo) and equipment thereof

A technology for containers and bulk cargo, which is applied in the field of loading and unloading of berths at ports and terminals, and can solve problems such as overturning safety accidents, exceeding the range of stone beds, and prolonged loading and unloading operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described below. (Bearing situation, loading and unloading situation and offshore situation)

[0022] Ship situation——

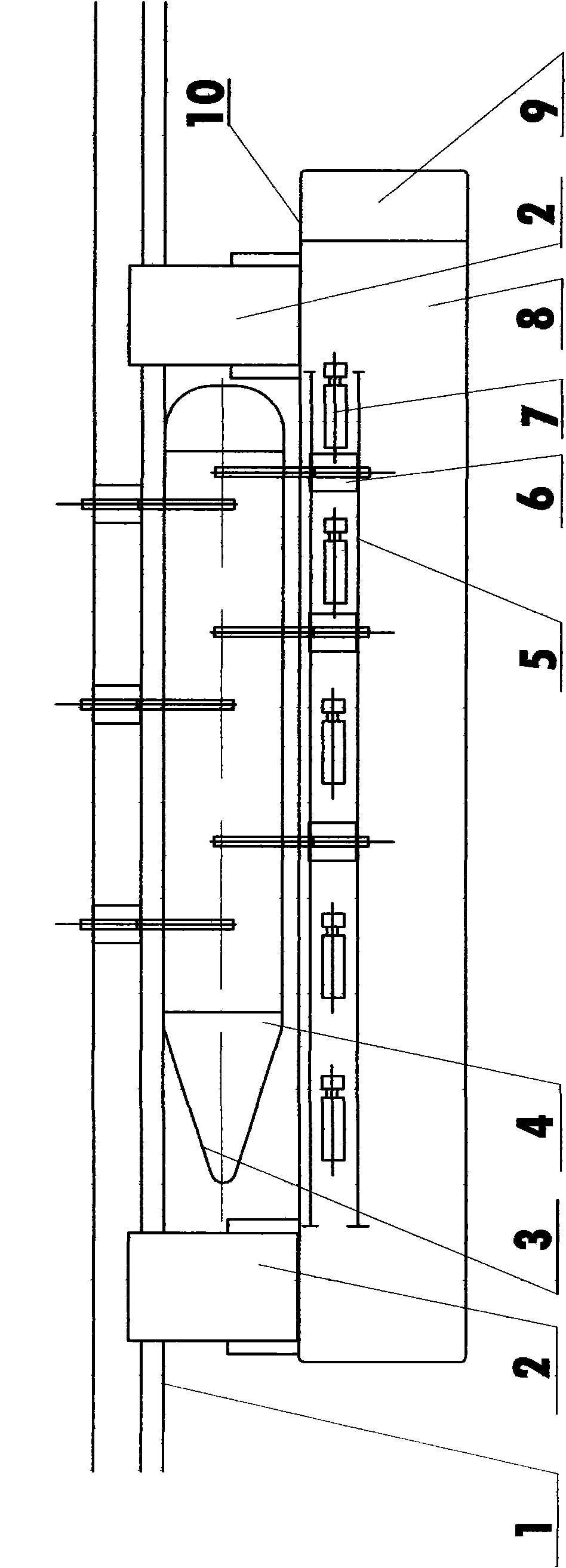

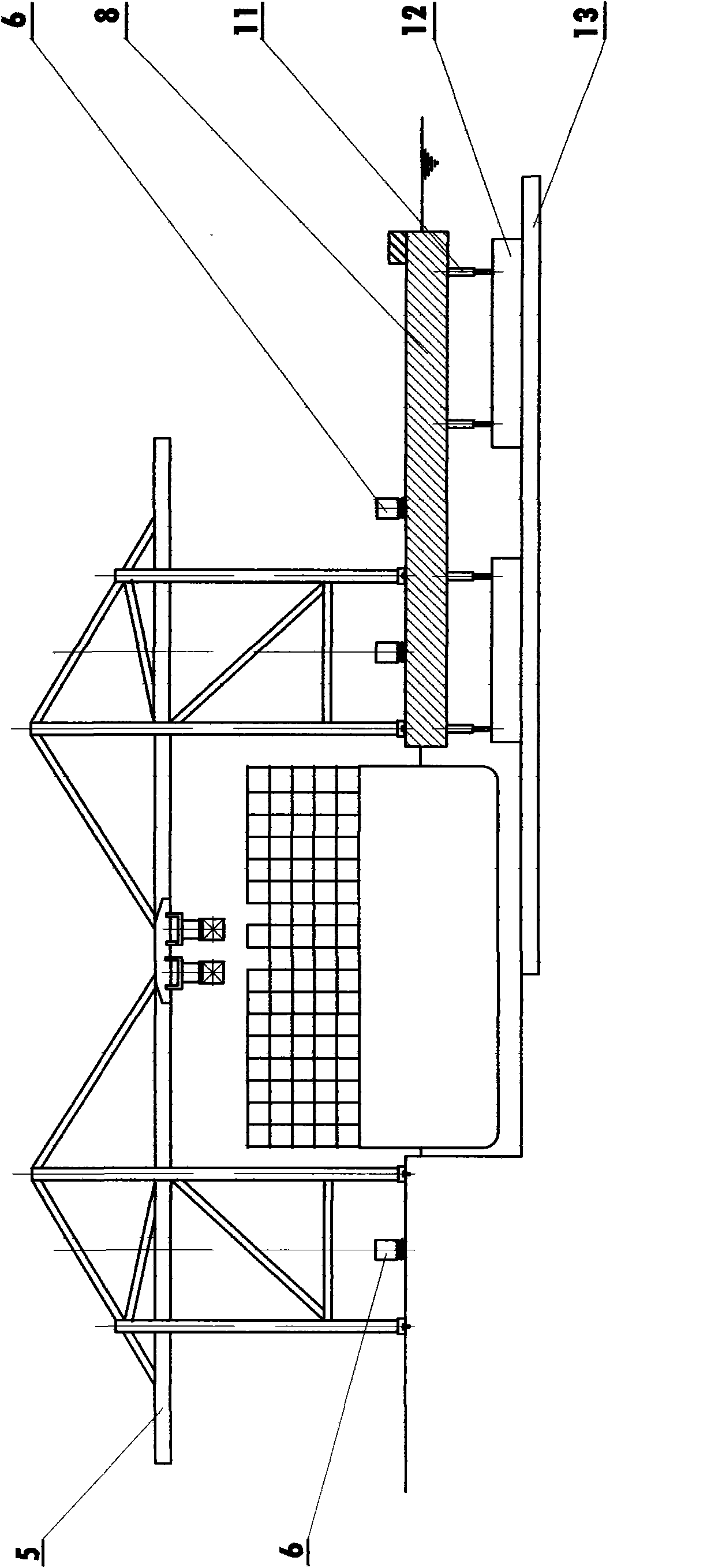

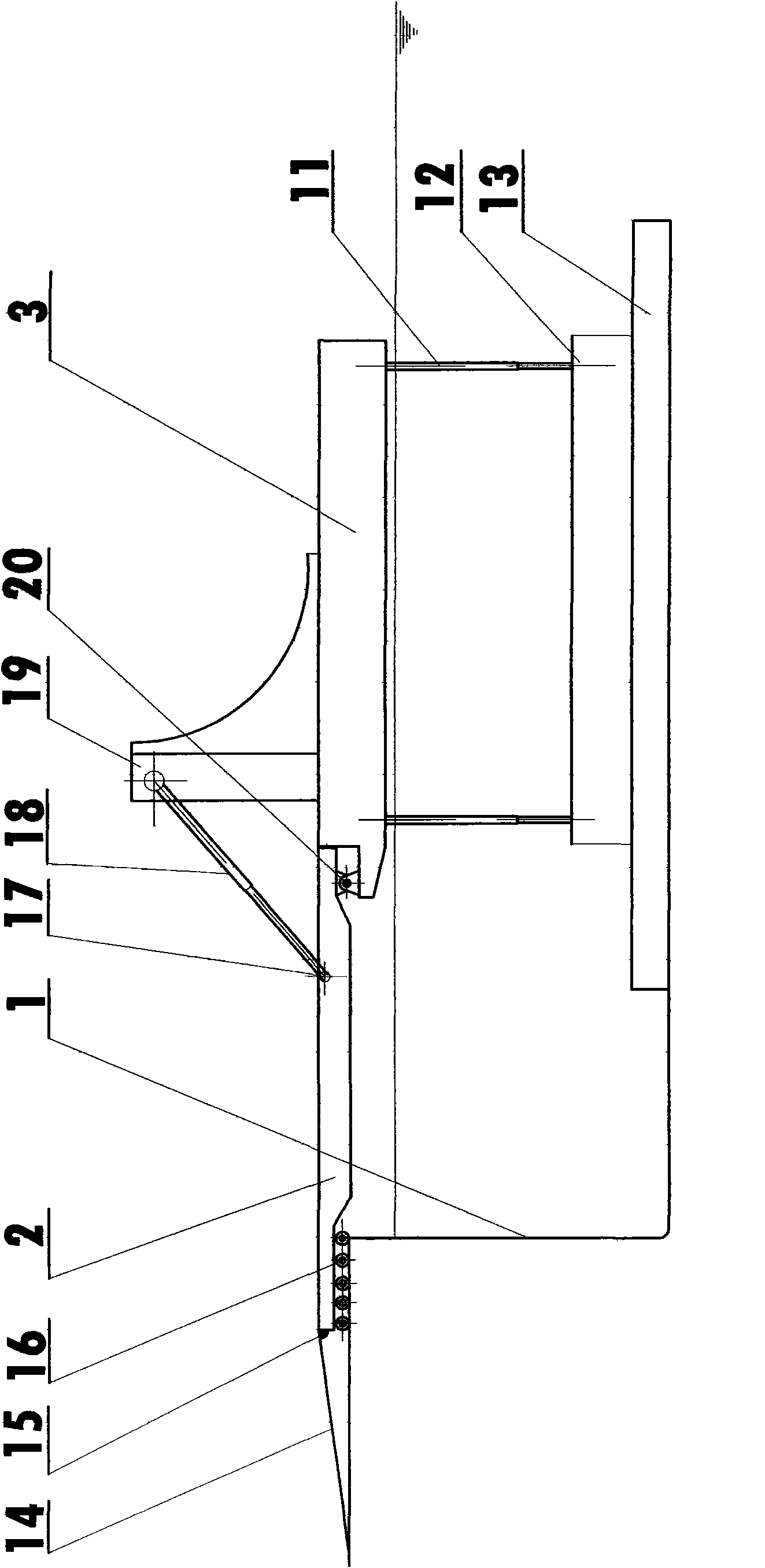

[0023] like figure 1 , figure 2 , image 3 As shown, when unloading by ship, the cargo ship (4) is close to the wharf wall (1), and the cargo ship (4) is fixed to the wharf wall (1) by fixing the mooring side (3) of the cargo ship, and then the floating wharf (8) After the cargo ship (4) stops firmly, after the cables on the mooring side (9) of the floating dock (8) are fixed to the dock wall (1), the connecting bridges (2) on both sides of the floating dock (1) are placed on the dock On the plane, prepare for loading and unloading operations.

[0024] Loading and unloading——

[0025] After the connecting bridge (2) is stabilized, the container trailer or horizontal transport machinery (7) drives the plane of the floating dock (8) from the dock, and the container bridge crane or gantry crane that has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com