Translational device for crane slings

A technology of translation device and crane, which is applied in the direction of transportation and packaging, load hanging components, etc., which can solve the problems of high fuel consumption, poor operator comfort, and heavy lifting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

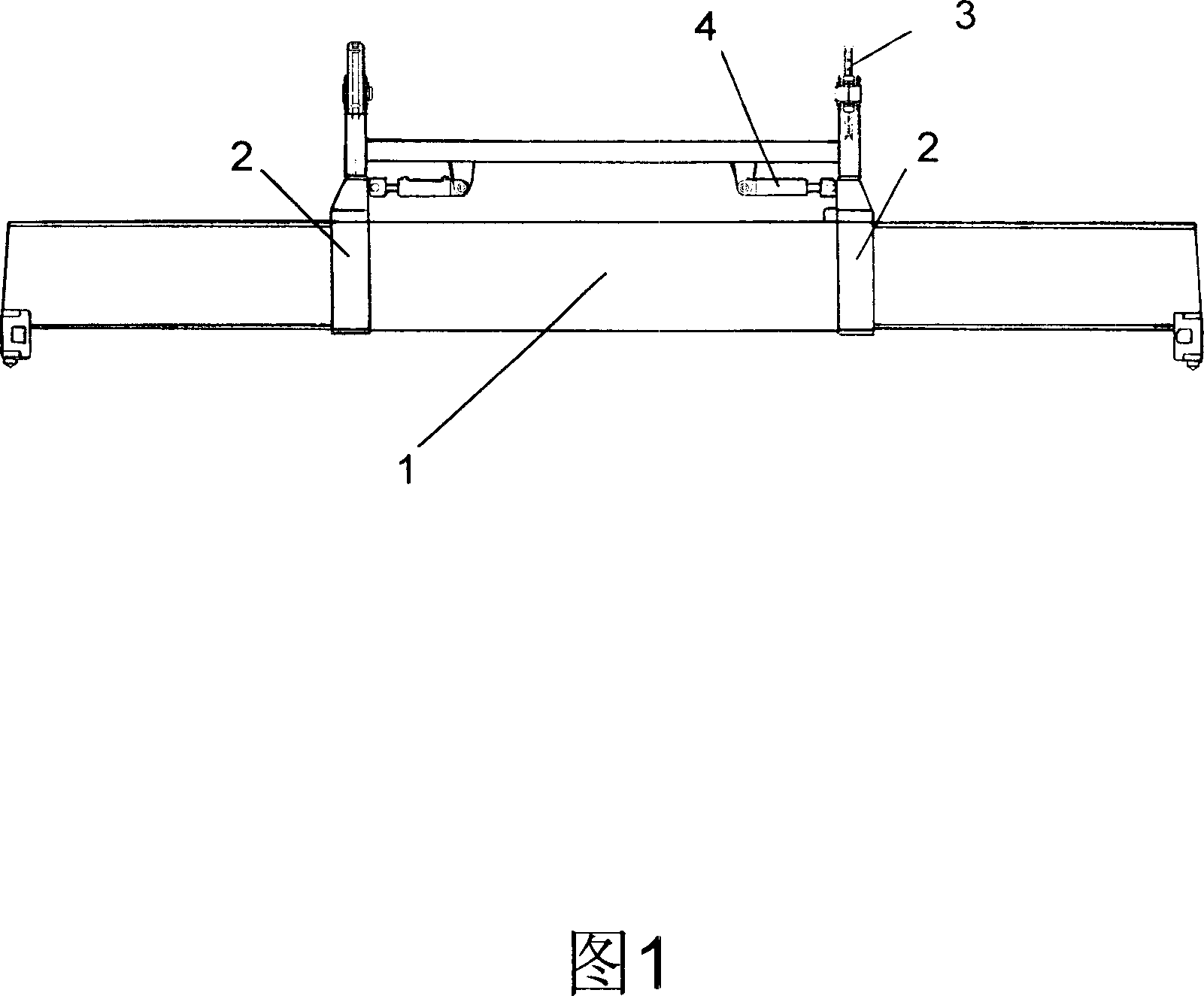

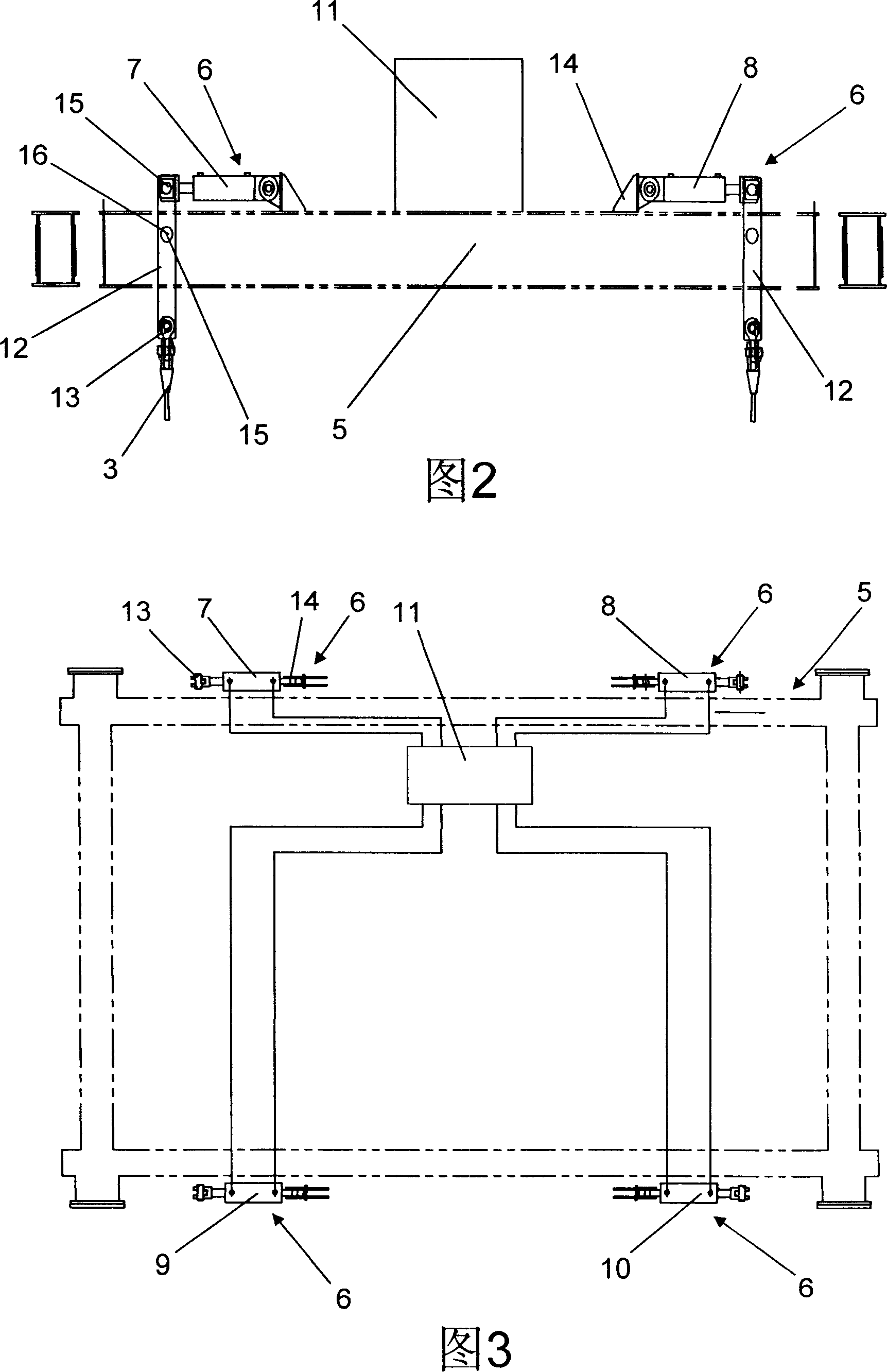

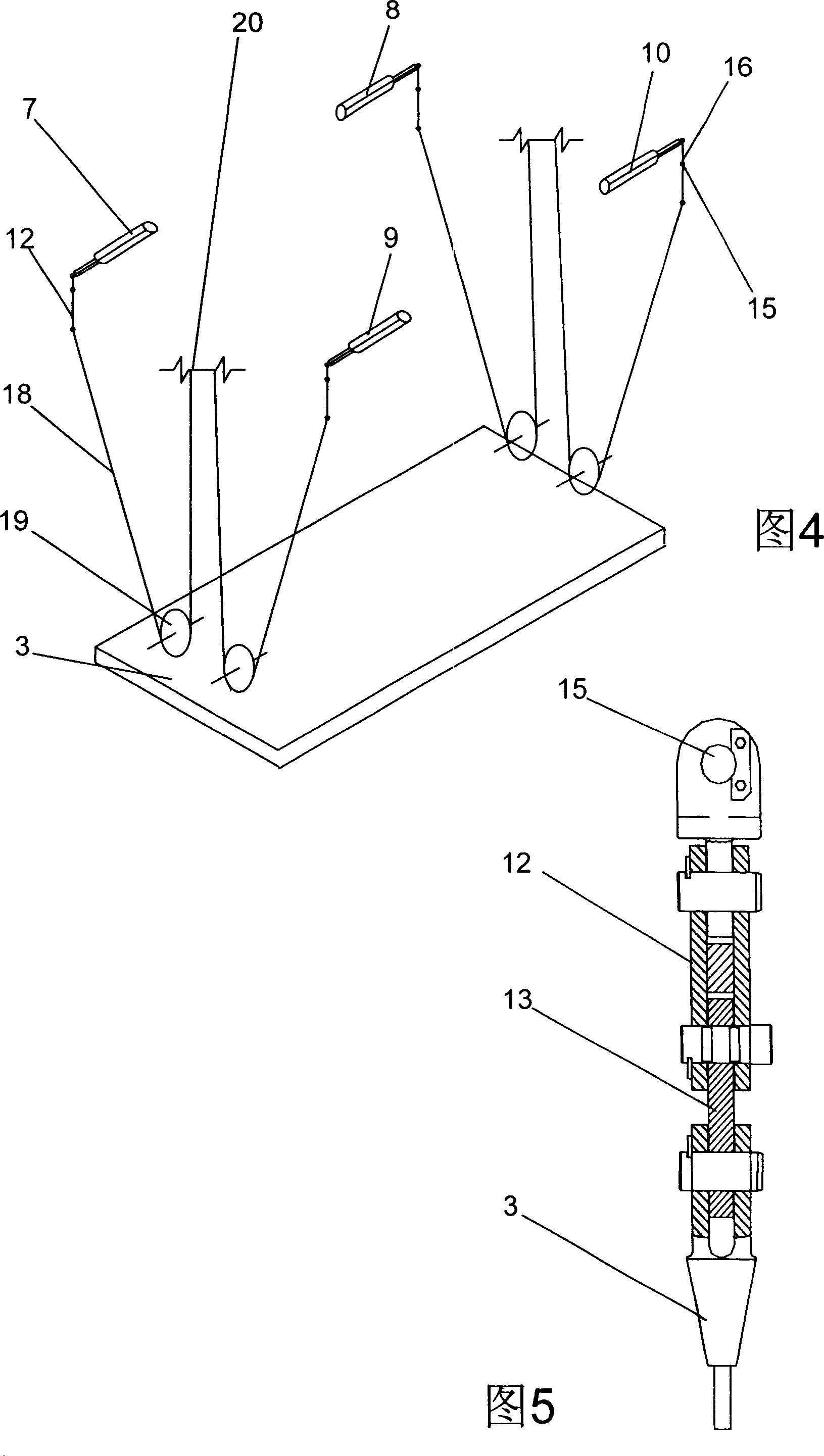

[0024] As shown in Figure 2 and Figure 3, the translation device includes a trolley 5 and a driving device 6, the driving device is arranged on the trolley 5, and the driving device 6 further includes: hydraulic cylinders 7, 8, 9, 10, hydraulic pump station 11. Lever 12 and wire rope winding system 13; there are four sets of hydraulic cylinders 7, 8, 9, and 10, which are located on both sides of the trolley 5 in pairs, and the two hydraulic cylinders 7, 8 or 9, 10 on the same side are spaced apart For a certain distance, one end support 14 of each hydraulic cylinder is fixed on the trolley 5 by welding, and the other end is provided with a lever 12 and connected to the upper end of the lever through a pin 15; the fulcrum 16 of the lever is fixed on the trolley 5 through the pin 15 The lower end of the lever 12 has a wire rope winding system 13 and is connected with the upper frame 3 of the spreader; the hydraulic pump station 11 is in the middle of four groups of hydraulic cyli...

Embodiment 2

[0027] On the original basis of Embodiment 2, a push rod device is used to replace the hydraulic cylinder and the pump station.

[0028] Please refer to Fig. 2, shown in Fig. 3, this translation device comprises trolley 5 and driving device 6, and driving device is arranged on trolley 5, and driving device 6 further comprises: push rod, lever 12 and wire rope winding system 13; Push rod (the push rod is similar to a common long rod, not shown in the figure) there are four groups, which are respectively located on both sides of the trolley 5 in twos, with a distance between the push rods on the same side, and one end of each push rod supports The seat 14 is fixed on the trolley 5 by welding, the other end is provided with a lever 12 and connected to the upper end of the lever through the pin 15; the fulcrum 16 of the lever is fixed on the side of the trolley 5 through the pin 15, and the lower end of the lever 12 is wound with a wire rope System 13 is also connected with hanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com