Hydraulic clamp of numerical control lathe

A technology of hydraulic fixtures and CNC lathes, applied in clamping, manufacturing tools, supports, etc., can solve the problems of poor size consistency of parts, high labor intensity of loading and unloading, and large fluctuation range of precision, and achieve low manufacturing ease and uniform pressing force Good performance and reliability, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

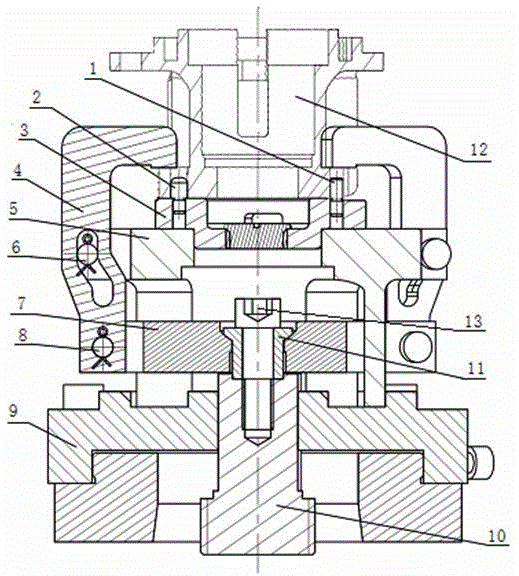

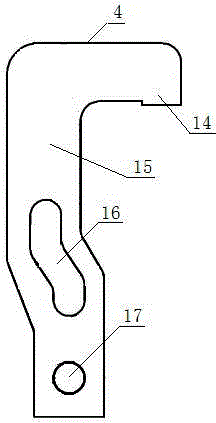

[0012] The numerical control lathe hydraulic clamp of the present invention comprises a body 5 , a positioning block 3 , a lever 7 , a connection plate 9 and a tie rod 10 . The body 5 is composed of a positioning platform and a supporting cylinder. There are three sliding bearings evenly distributed on the positioning platform. The sliding bearings are provided with sliding pins 6, and three through grooves are evenly distributed on the supporting cylinder. The positioning block 3 placed on the body 5 is provided with a diamond-shaped positioning pin 1 and a circular positioning pin 2 . The lever 7 is made of three connecting rods uniformly distributed on the disc and the circumference, the center of the disc is provided with a connecting hole, and a spherical bushing 11 is built in the connecting hole. The connecting rod is connected with a hook-shaped pressing plate 4, and the connecting rod and the hook-shaped pressing plate 4 are rotatably connected by a rotating pin 8. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com