Self-walking gantry lifting device

A lifting device and self-propelled technology, which is applied in the direction of hoisting equipment braking device, hoisting device, transportation and packaging, etc., can solve problems such as lifting work that is not suitable for cylindrical equipment, and achieve saving loading and unloading time, low site requirements, The effect of multiple application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

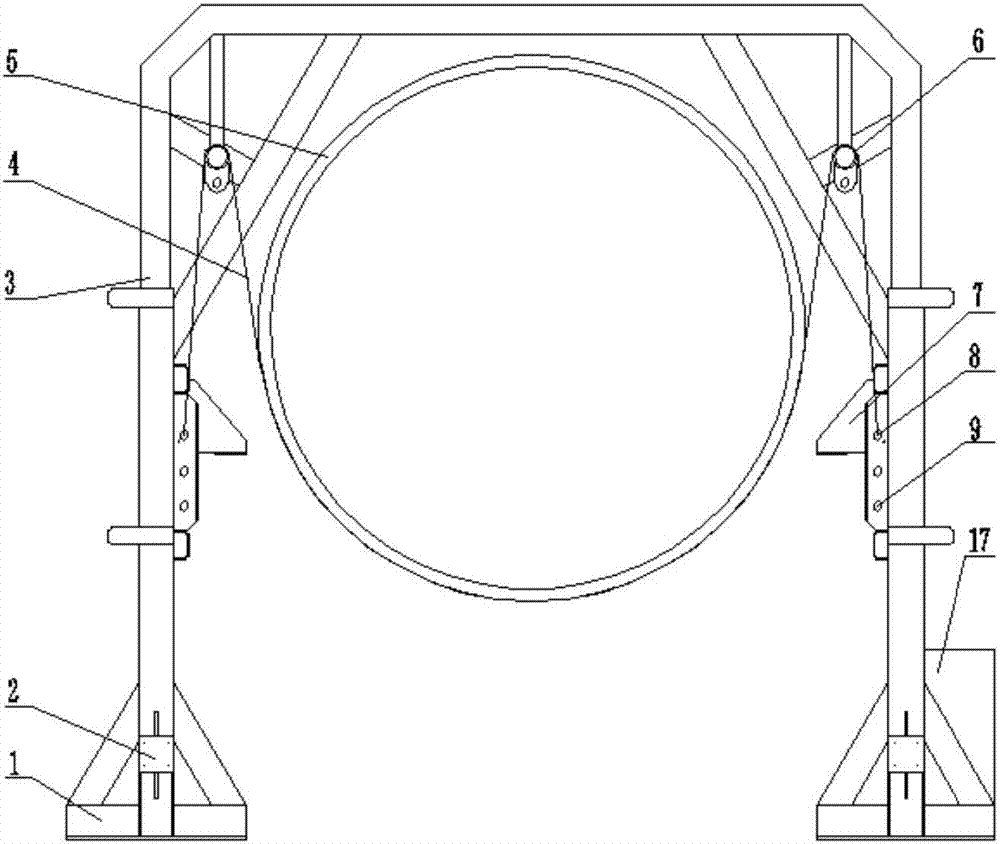

[0026] figure 1 The structure of the present invention is shown. A self-propelled gantry lifting device comprises a main girder, supporting feet, a lifting mechanism, a self-propelling mechanism and an adjustable hoisting mechanism. A support 7 is arranged on the inner side of the foot along the direction of the main beam.

[0027] 1. Lifting mechanism

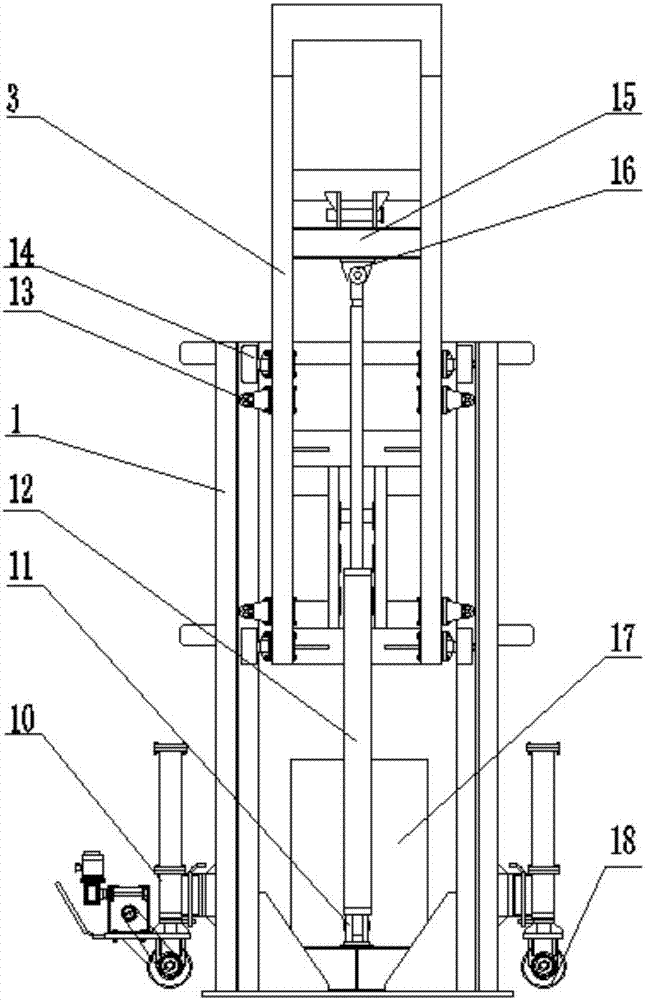

[0028] figure 2 The structure of the crane 3 is shown. The support foot includes a frame base 1 and a column, and a lifting mechanism is arranged on the column. The lifting mechanism includes a lifting frame 3 and a jacking hydraulic telescopic cylinder 12. The lifting frame 3 is nested into the column of the supporting foot in a "U" shape. And form a gantry structure with it, the beam of lifting frame 3 is the main beam. The upper ends of both sides of the lifting frame 3 are sequentially provided with a fixed seat 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com