Controlling method for adjusting paper running of paper filter

A control method and filter technology, applied in electrical program control, program control in sequence/logic controllers, manufacturing tools, etc., can solve the problem of high frequency of floating and falling, increased consumption of filter paper, long time, etc. problems, to achieve the effect of reducing the soaking time and area, reducing the probability of corrosion and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

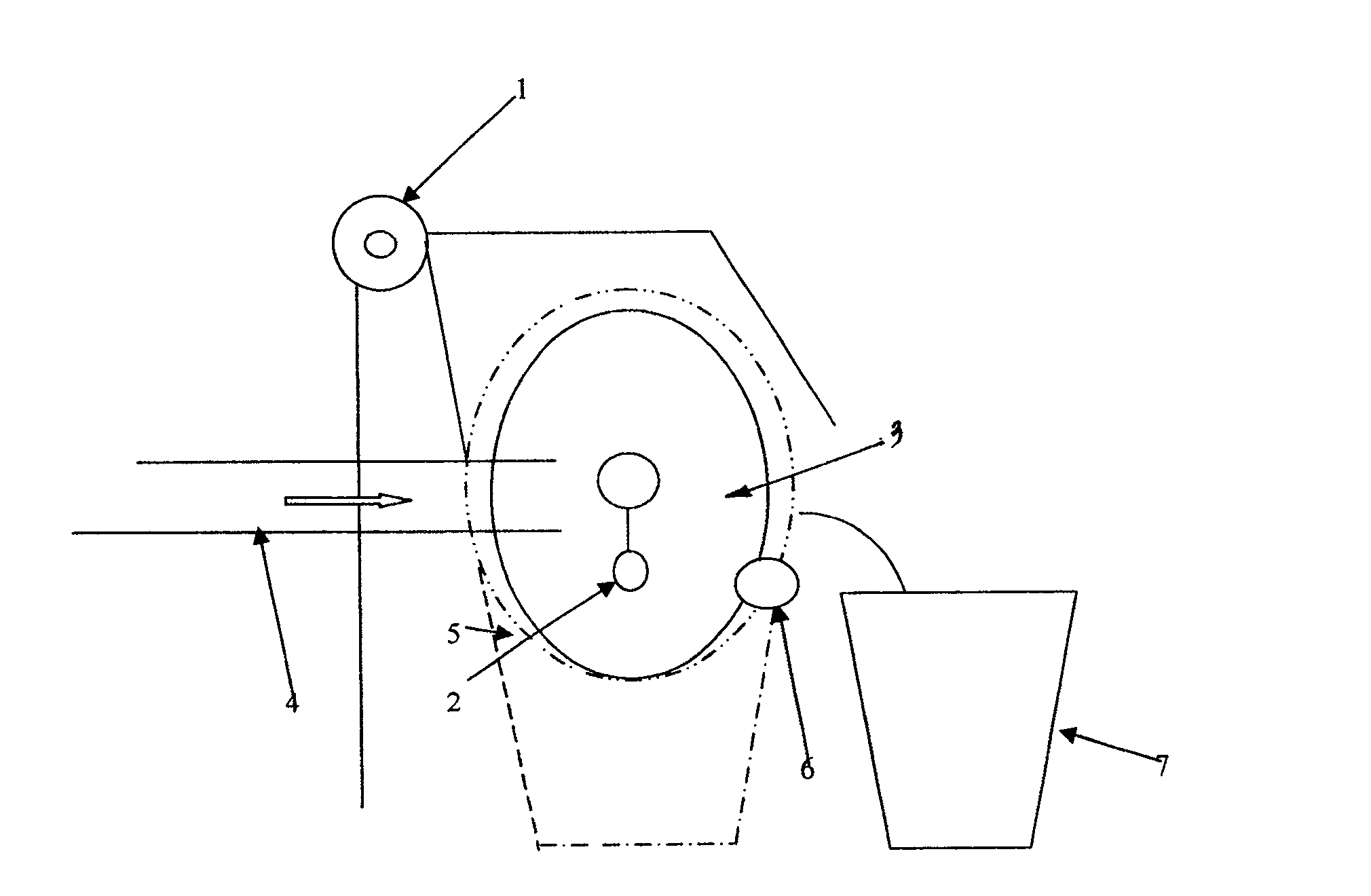

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

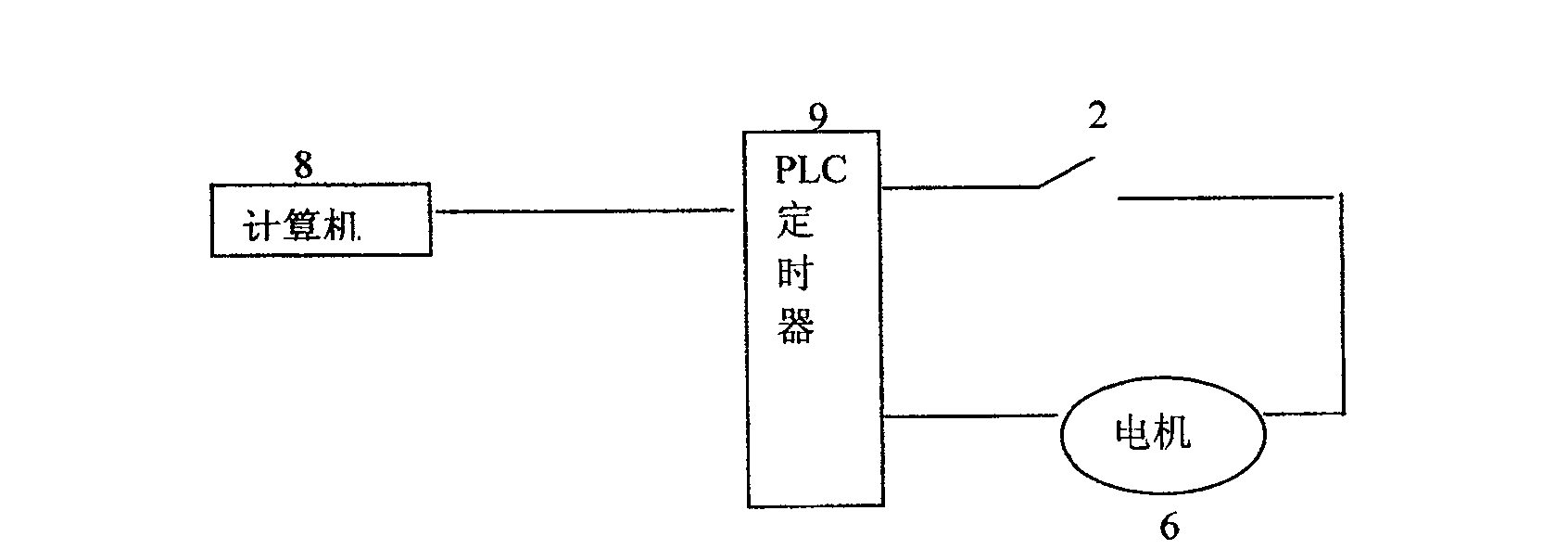

[0016] First, adjust the height of the float 2 located on the upper part of the filter paper 1 of the paper tape filter, and according to the height and volume of the liquid accumulation tank 3 and the flow rate of the grinding fluid 4, determine that the position of the float 2 is 300mm away from the bottom surface of the filter paper 1 , so that it is in the best position.

[0017] Secondly, adjust the length of the external cable that float 2 is connected with computer 8, according to the result of actual measurement, it is determined at 150mm, the sensitivity of float 2 is adjusted to the best state.

[0018] At the same time, determine a reasonable paper-feeding time, that is, the setting time, according to field tests and measured data. Its basis is that the time that the filter paper 2 that the solid particles are deposited in the actual measurement is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com