High-efficiency soldering process of circuit board connector

A welding process and connector technology, which is applied in the field of welding process of circuit board connectors, can solve the problems of wasteful production and processing costs, large amount of solder bars, low work efficiency, etc., so as to improve production efficiency, improve welding quality, and reduce rework. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

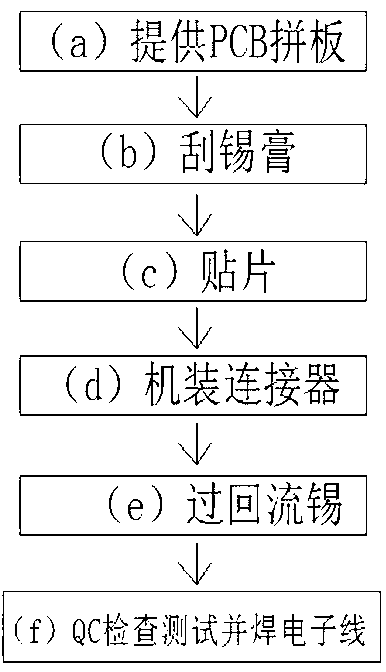

[0026] In this embodiment, refer to figure 1 with figure 2 , a welding process of an efficient circuit board connector, characterized in that the welding process includes the following steps;

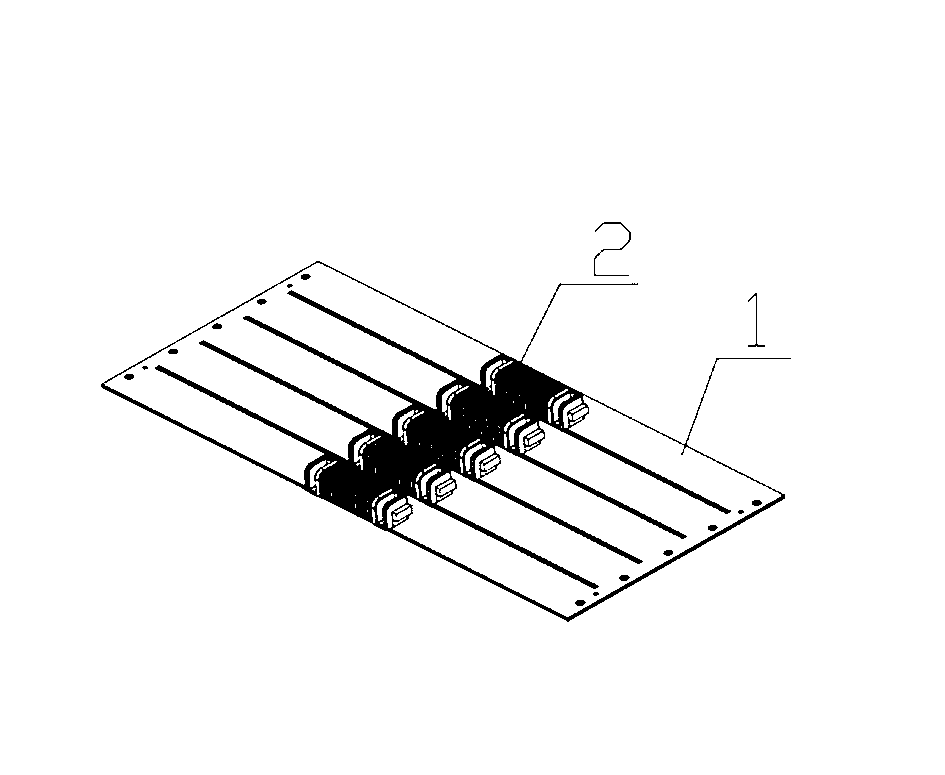

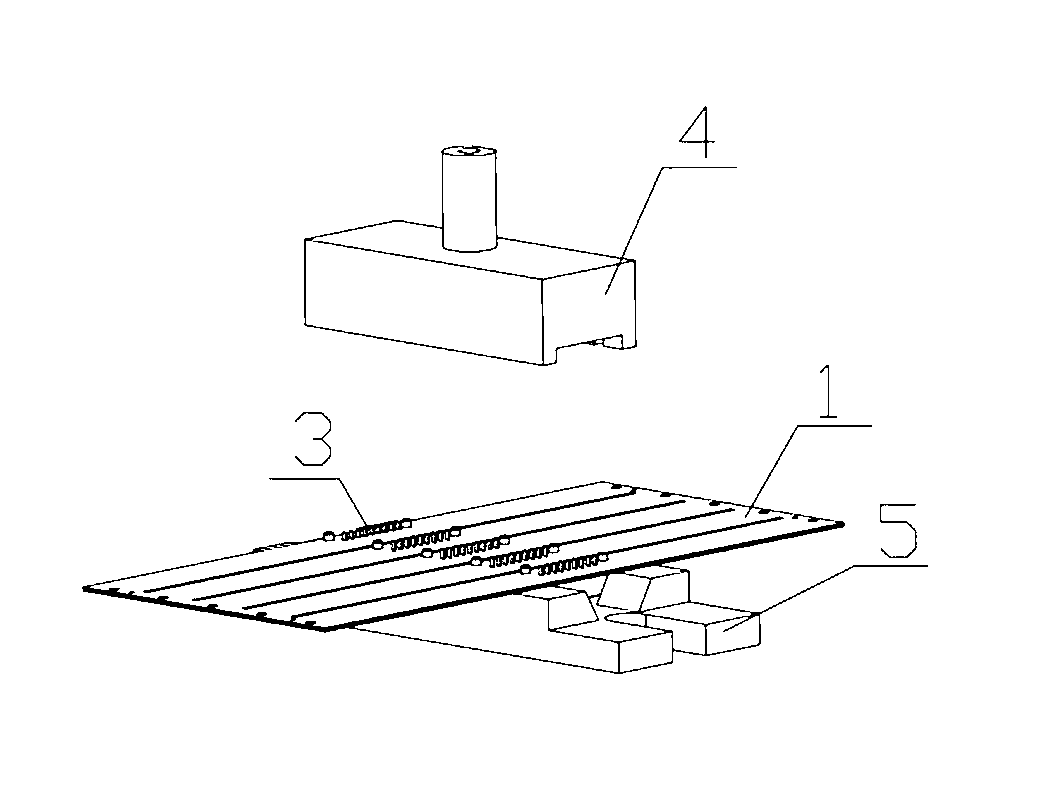

[0027] (a) Provide PCB panel 1. The PCB panel 1 refers to the splicing of multiple small PCB boards of the same type on a larger board. The small PCB boards of the same type are square boards with the same size. Combined and spliced as one, and has multiple circuit layers, and the PCB panel 1 is provided with at least one welding hole, which is used to mount components, including horizontal rows of connector welding holes, the connector welding holes are used To insert the connector pin 3, the welding hole is electrically connected to the circuit layer;

[0028] (b) Scraping solder paste. The function of solder paste is to ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com