Manufacturing method of connecting wire with high-definition multimedia interface

A multimedia interface, high-definition technology, applied in connection, contact assembly/disassembly, circuit/collector parts, etc., can solve problems such as poor appearance, increased manufacturing cost, shrinkage, etc., to eliminate the problem of poor electrical performance and appearance problems, saving manpower and financial resources, reducing the effect of rework rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The manufacturing method of the connection line with high-definition multimedia interface of the present invention will be further described in detail below in conjunction with the accompanying drawings.

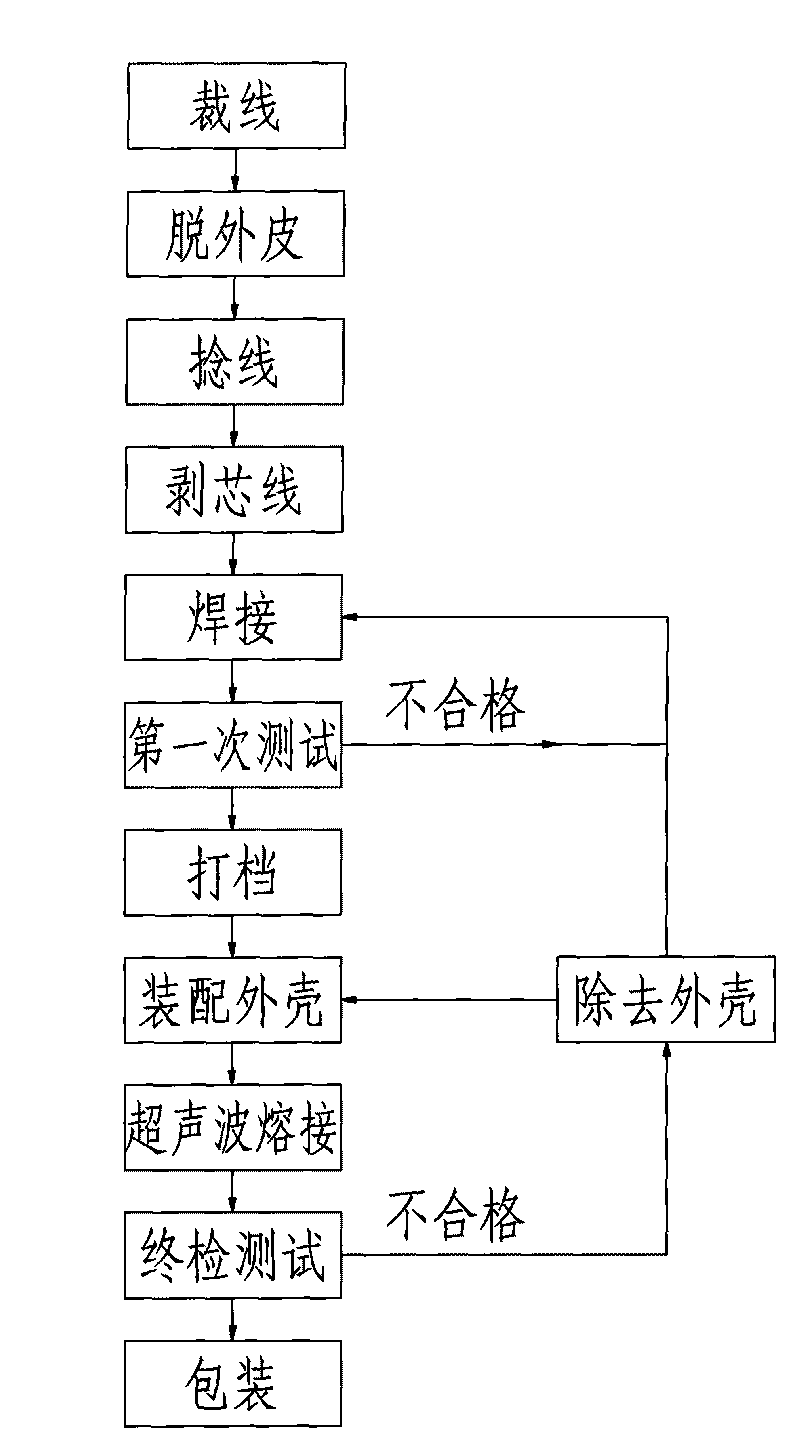

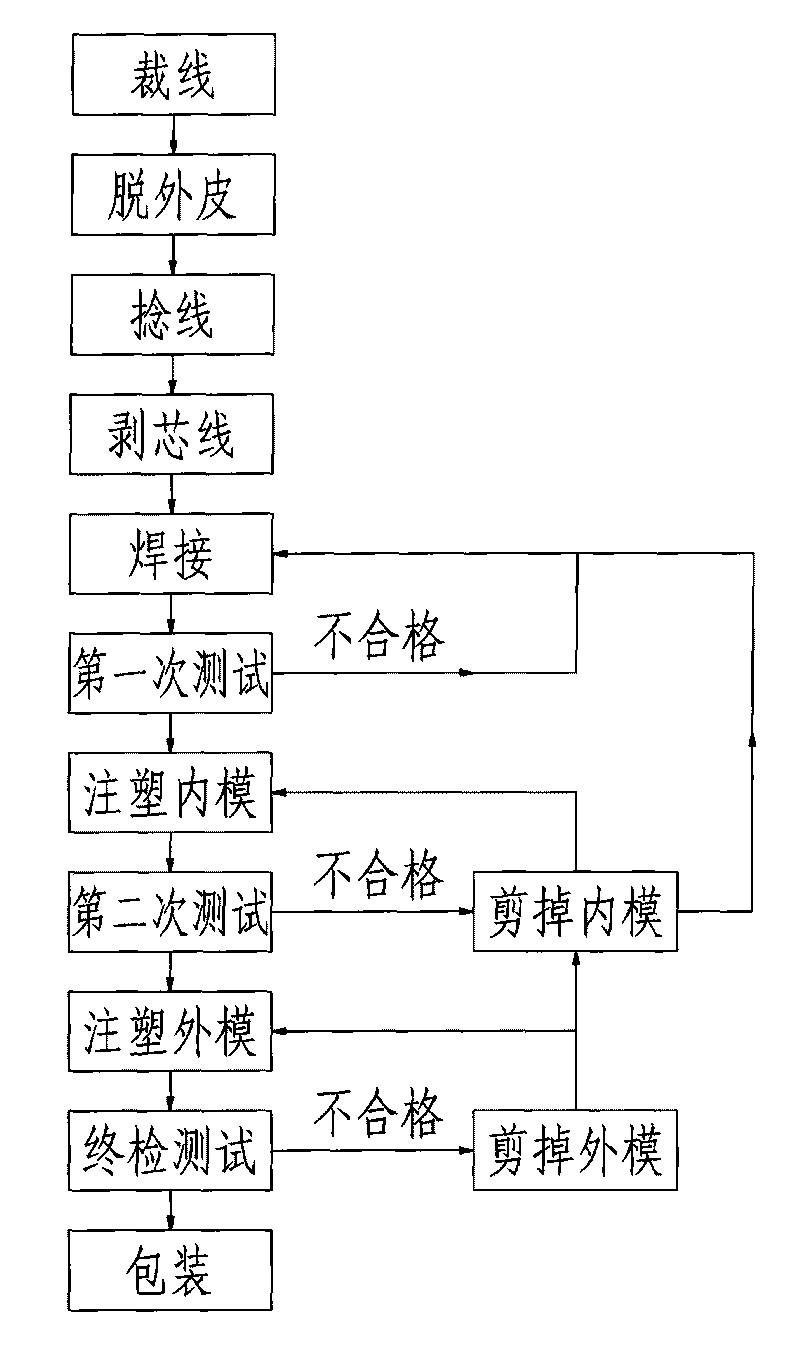

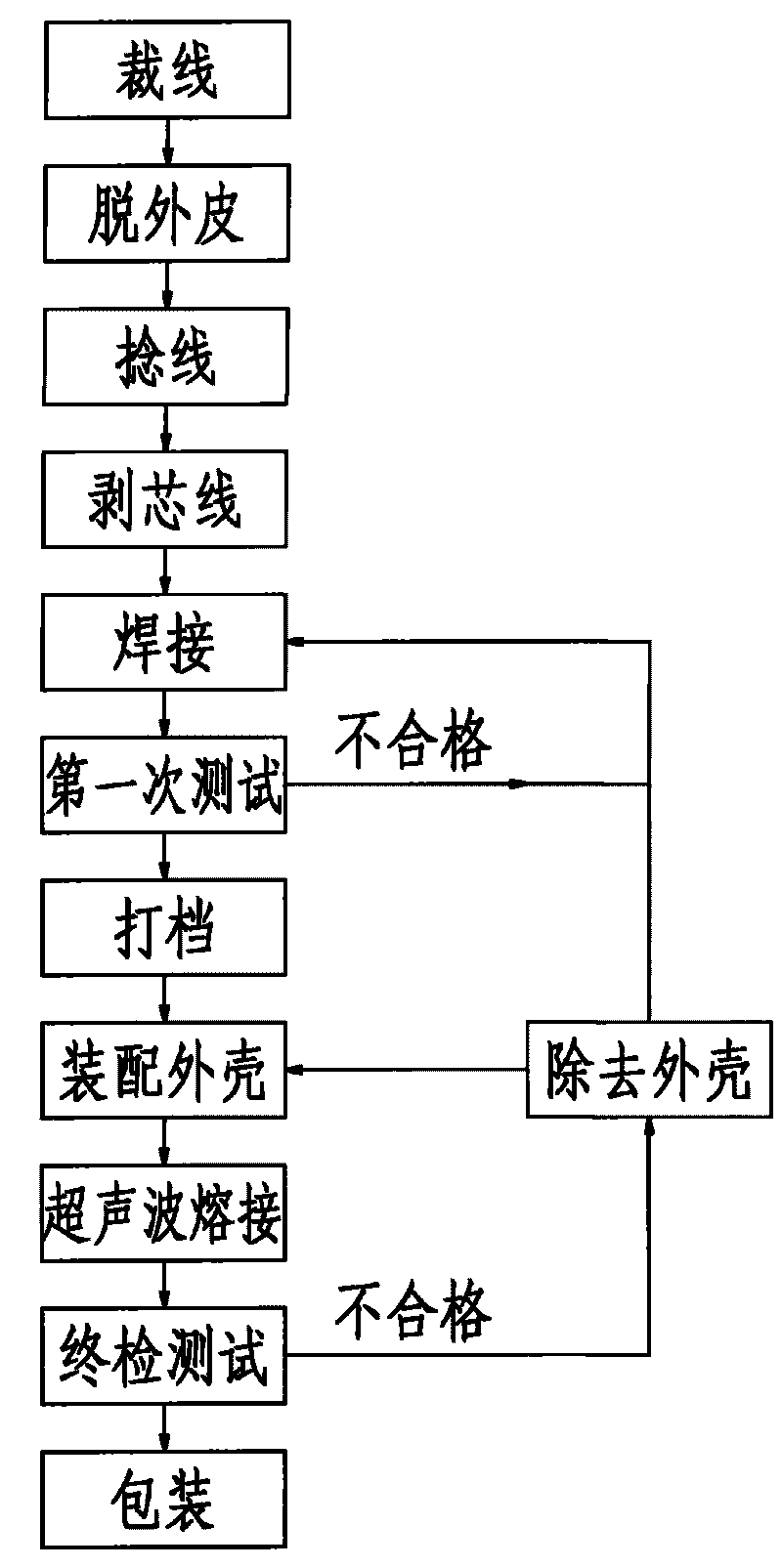

[0012] Such as figure 1 As shown, the manufacturing method of a connecting wire with a high-definition multimedia interface includes the following process: 1. Cutting: according to customer needs, the cable is cut to a specified length; 2. Sheathing: the outer sheath at the end of the cable Strip to the specified length to expose the shielded wire layer; 3. Twisted wire: pick out 6-10 strands of braided shielded wire from the shielded wire layer and use a twister to twist them into a spare strand, cut off other redundant shielded wires, and expose the middle Core wire; 4. Core wire stripping: strip the insulation of the middle core wire to a specified length of 3.0±0.4mm; 5. Welding: weld the middle core wire and shielding wire to the corresponding terminal in the HD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com