Measuring mechanism for assembling and press-loading vehicle main reducing gear

A technology of main reducer and measuring mechanism, which is applied in the testing of machine gear/transmission mechanism and measuring torque/torsional force during tightening. It can solve the problems of low efficiency, cumbersome process, high rework rate, etc., and achieve low rework rate and easy handling Fast, the effect that meets the process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

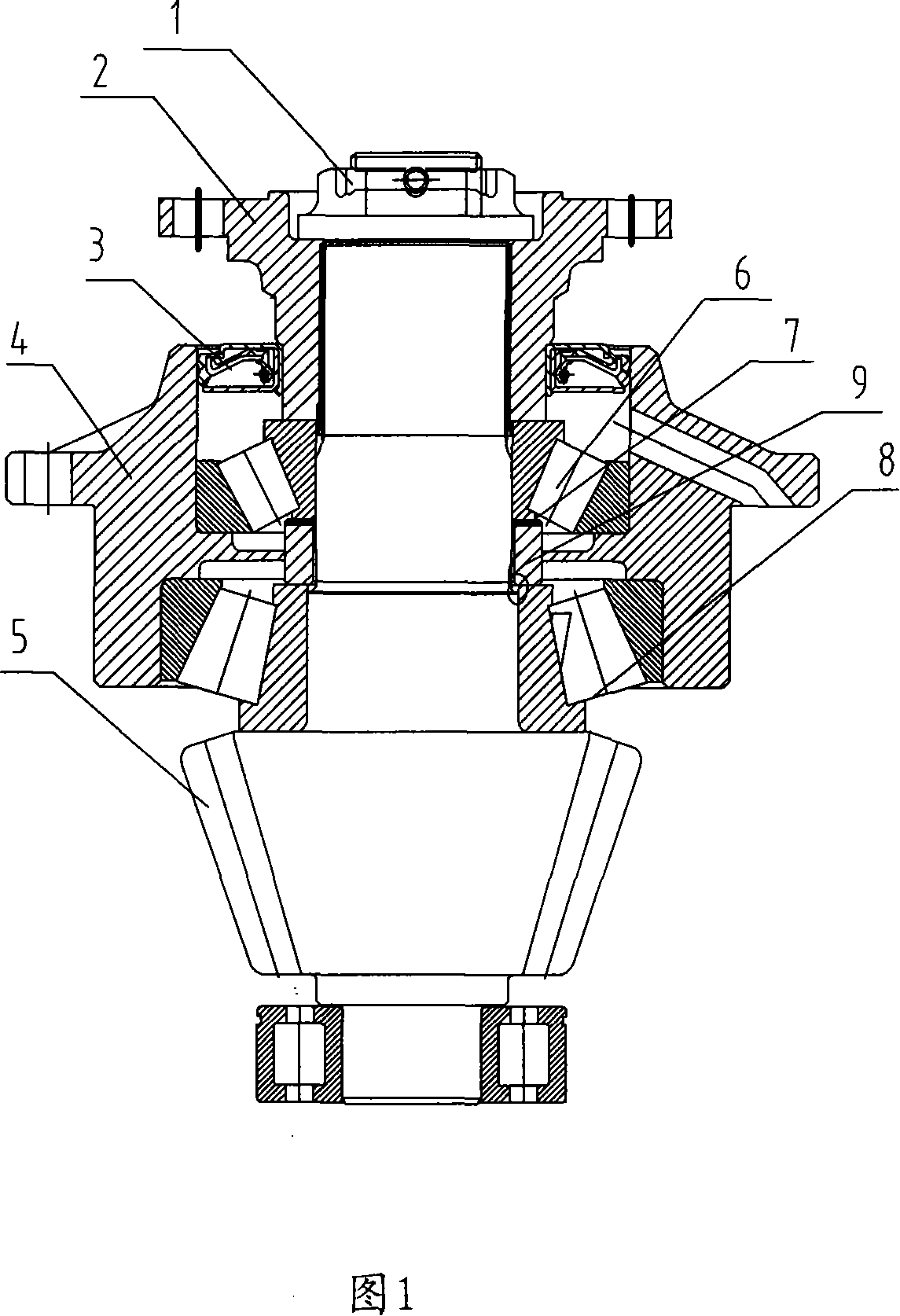

[0027] Referring to Fig. 1, the main tooth assembly involved in this embodiment includes a lock nut 1, a main tooth flange 2, an oil seal 3, a bearing seat 4, a driving gear 5, an upper bearing 6, an adjusting gasket 7, and a lower bearing 8 and spacer 9.

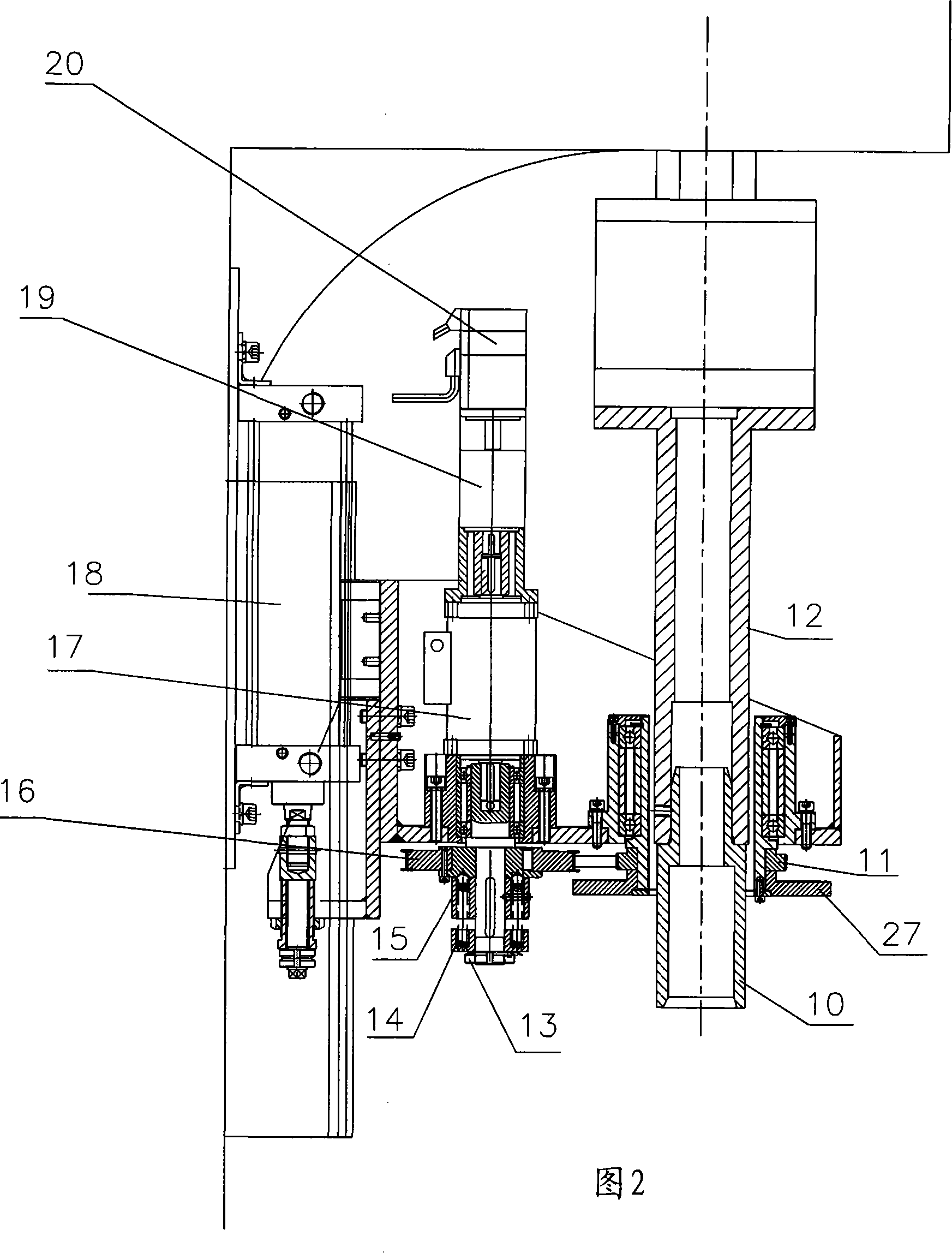

[0028] Referring to Fig. 2, the friction torque detection mechanism of the bearing seat is driven by a servo motor 20, and a speed reducer 19 and a dynamic torque sensor 17 are arranged between the drive source and the output mechanism. The shaft is connected with the output end of the speed reducer 19 and the shaft connecting the synchronous pulley I 16 respectively through the flat key, and the synchronous belt realizing speed and torque transmission is set between the synchronous pulley I 16 and the synchronous pulley II 11. A dial 27 is arranged below the pulley II 11, and a flexible shift fork 21 extending into the bolt hole of the bearing seat 4 is connected to the bottom of the dial 27 by screws, and the rotating fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com