Backlight module and flat-panel display

A flat-panel display and backlight module technology, applied in the direction of instruments, optics, electric light sources, etc., can solve the problems of increased manufacturing cost, fragmentation, and difficulty in rework, and achieve the effect of reducing the size of the appearance and reducing the offset rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The invention provides a backlight module with an engaging structure. When the backlight module is combined with the plastic frame and the lampshade, the relative movement of the two in the horizontal direction and the vertical direction can be positioned to reduce the assembly error of the backlight module.

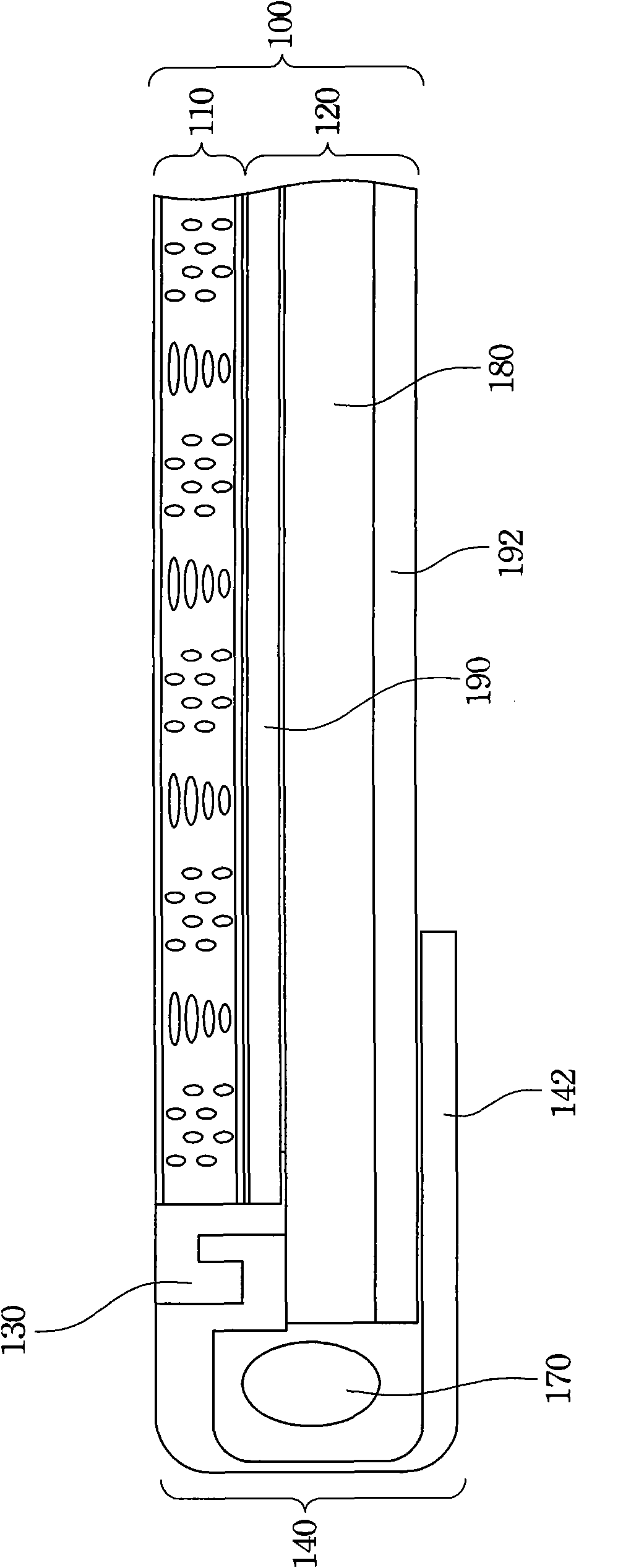

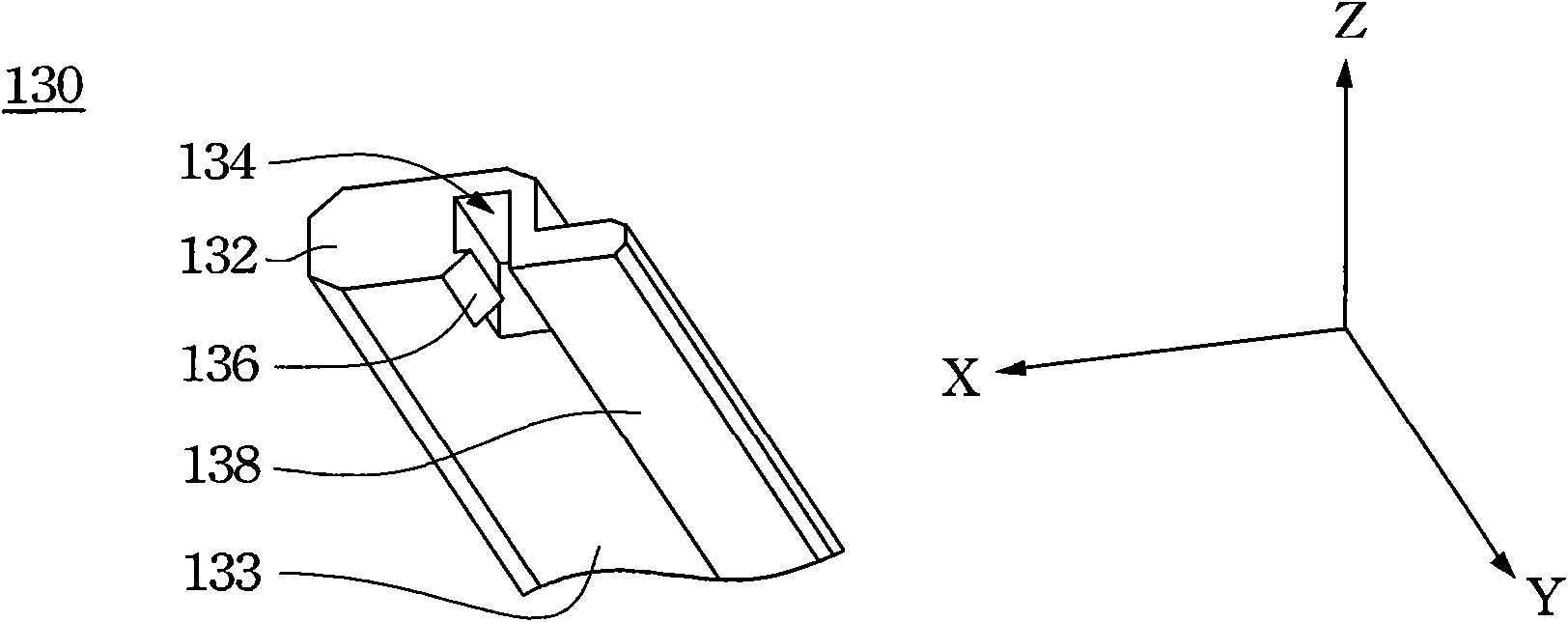

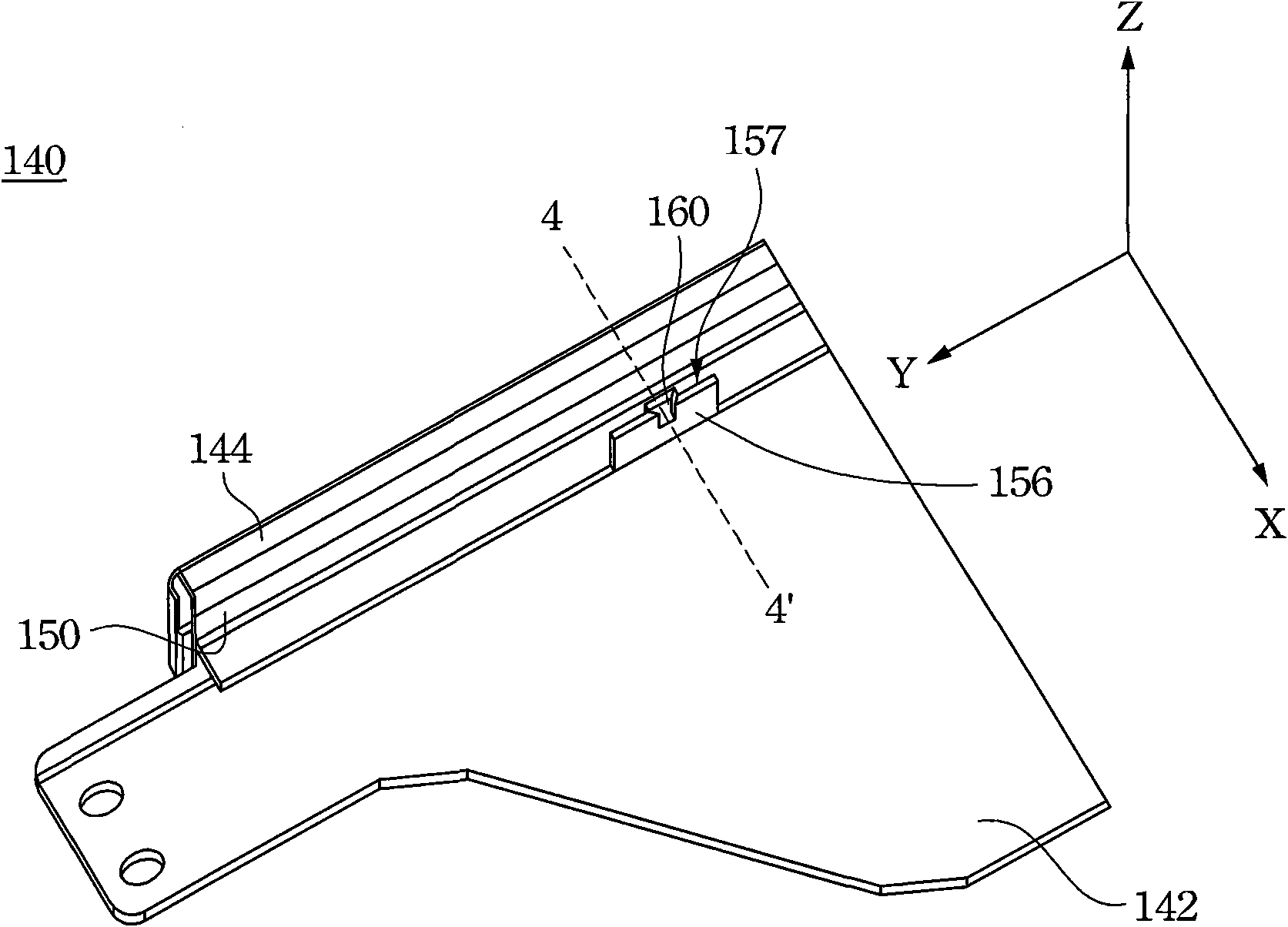

[0062] figure 1 A partial cross-sectional view of a flat panel display according to a preferred embodiment of the present invention is shown. In this embodiment, the flat panel display 100 includes a display panel 110 and a backlight module 120 , wherein the components of the backlight module 120 include a plastic frame 130 , a lampshade 140 , a light source 170 , a light guide plate 180 , an optical film 190 and a reflector 192 . The display panel 110 is located on the backlight module 120 , and the lampshade 140 is disposed on one side of the backlight module 120 . The plastic frame 130 and the lampshade 140 are engaged with each other, and the inner edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com