Patents

Literature

68results about How to "Reduce the probability of drift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

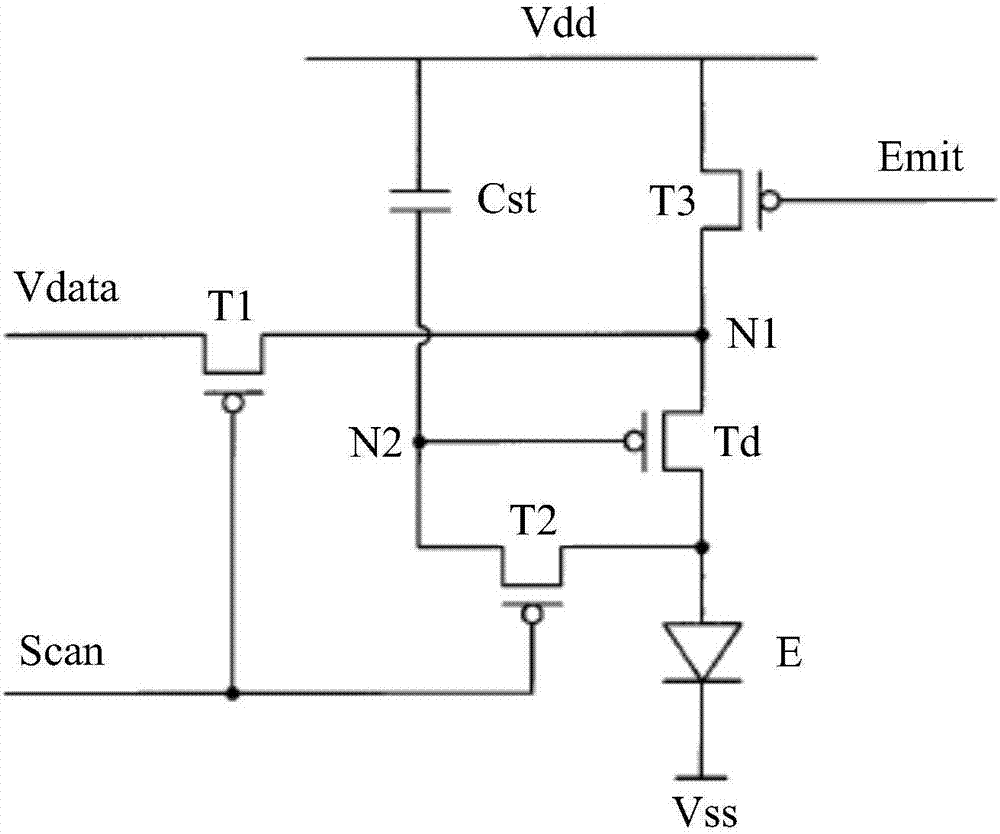

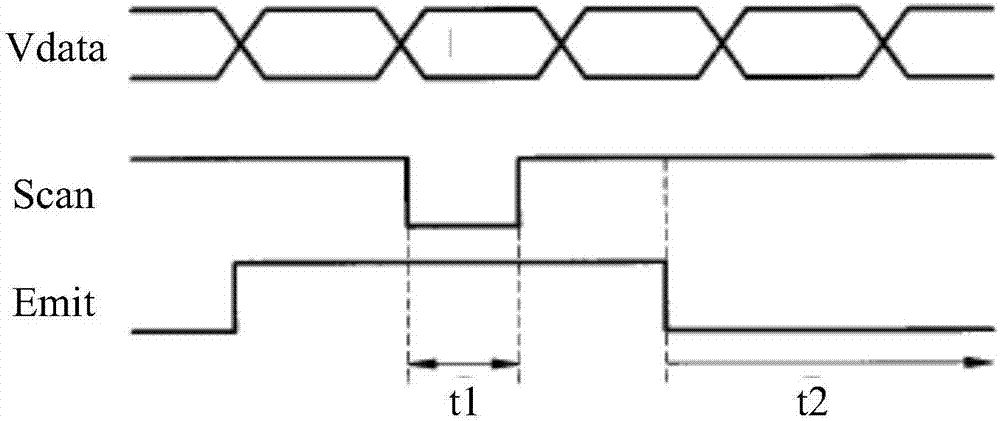

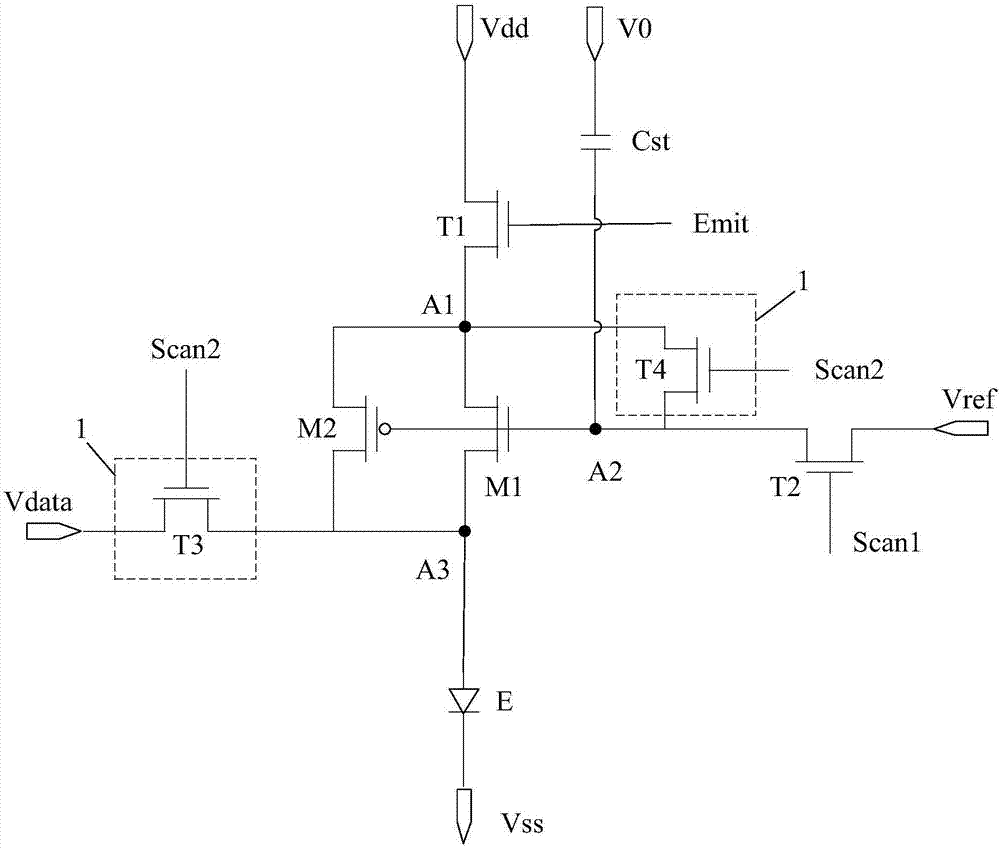

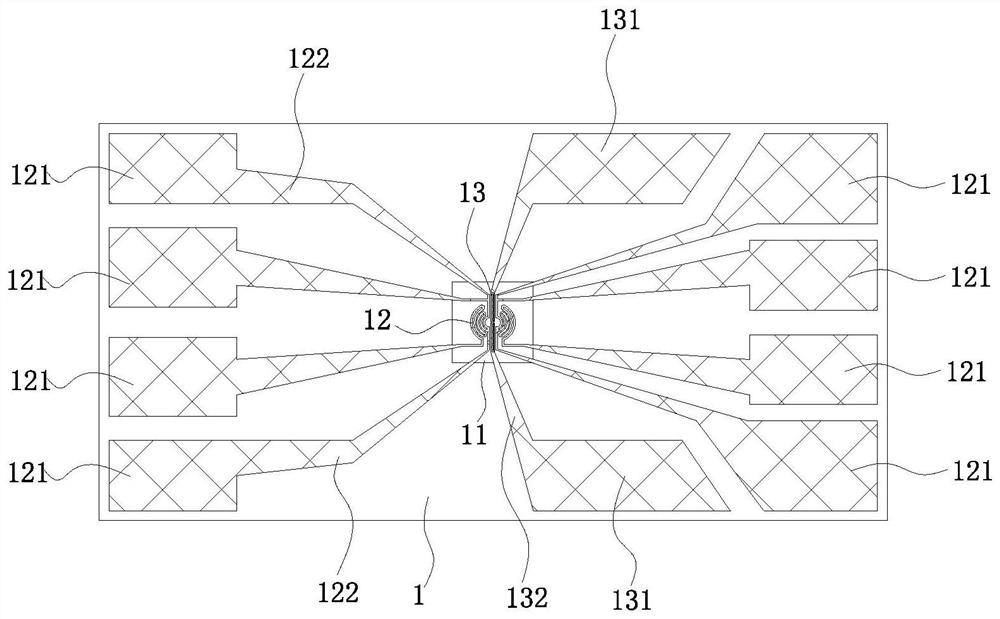

Pixel driving circuit and control method thereof, display panel and display apparatus

ActiveCN107342043AReduce the probability of driftReduce the impact of the threshold compensation effectStatic indicating devicesDriving currentSwitching signal

The invention provides a pixel driving circuit and a control method thereof, a display panel and a display apparatus, relating to the technical field of display and reducing the drifting probability of the threshold voltage of the driving transistor to thereby improve the display defect caused by the drifting probability. The pixel driving circuit includes a first transistor for transmitting the signal of a first power voltage end to a first node in response to the enable signal of a light-emitting signal control end; a first driving transistor for generating the driving current on the conducting path from the first node to a third node according to the enable signal of a second node, the first driving transistor being an N-type transistor; a second driving transistor for generating the driving current on the conducting path from the first node to the third node according to the enable signal of the second node, the second driving transistor being a P-type transistor; and a second transistor for transmitting the signal of a polarity switching signal end to the second node in response to the enable signal of a first scanning signal end.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Sole

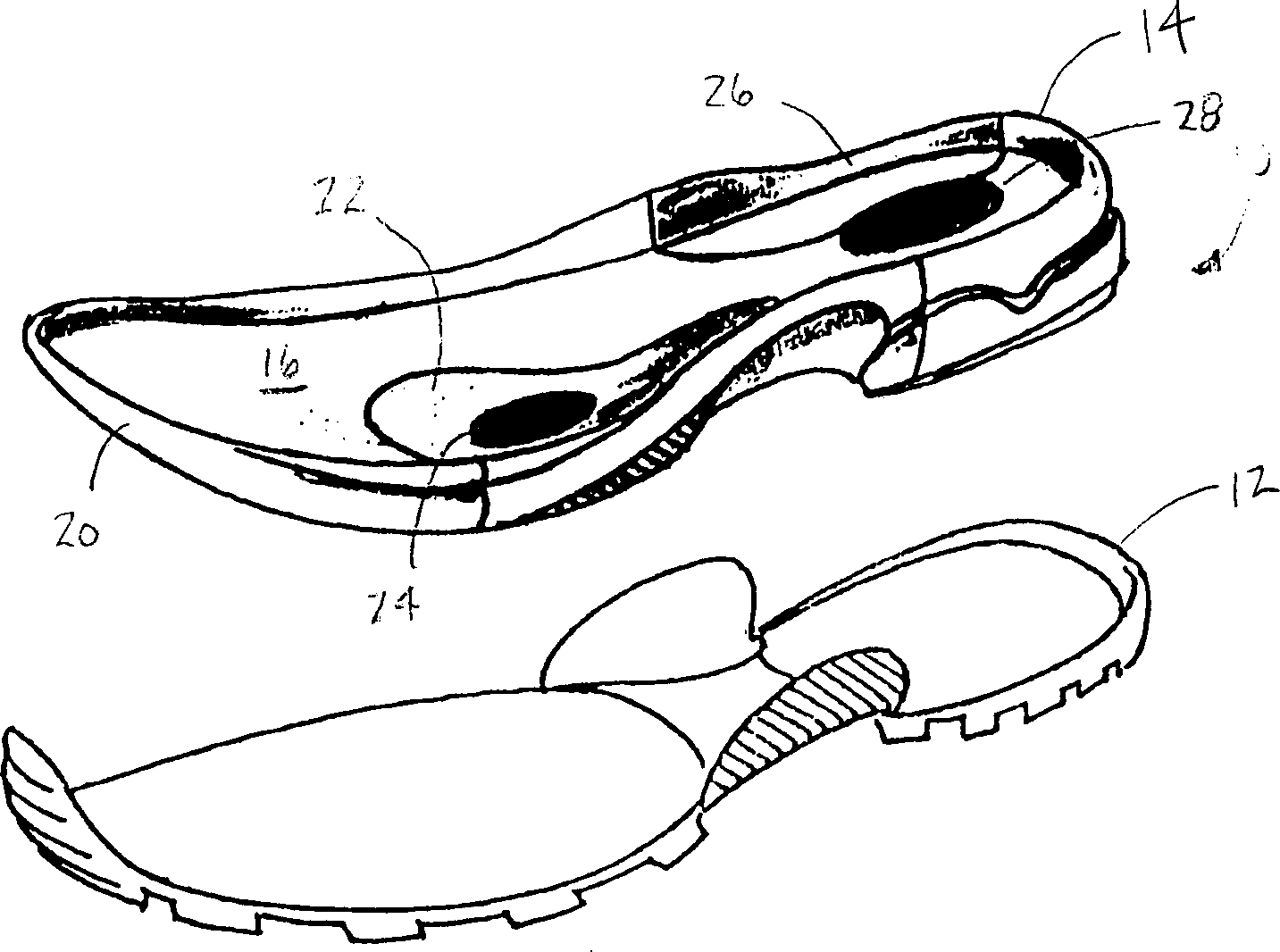

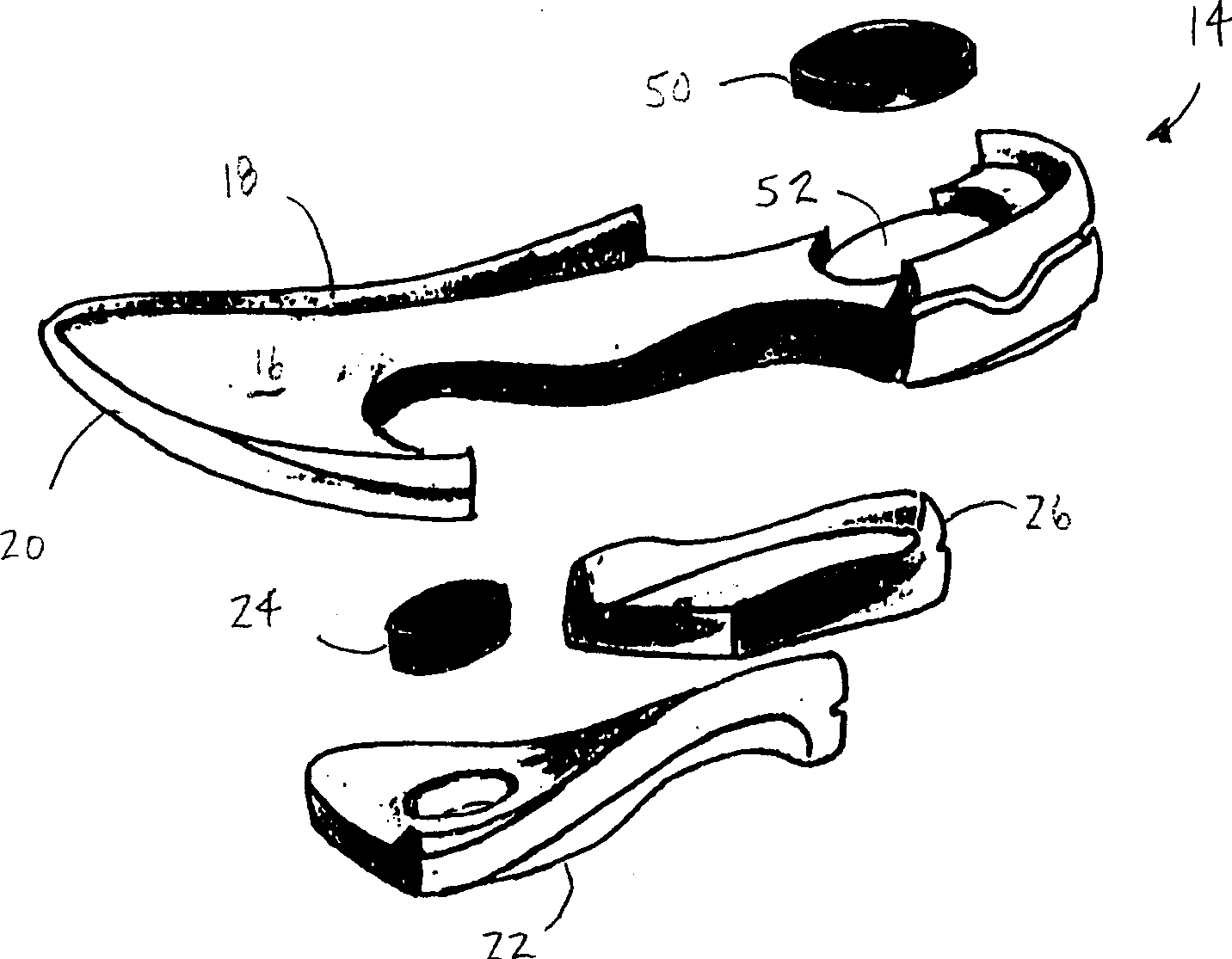

A sole component for women's footwear, designed specifically for women's biomechanics. The sole assembly includes a lateral adjustment portion extending downwardly through an area below the distal end of the second metatarsal, the distal end of the fifth metatarsal, and the proximal end of the fifth metatarsal, and does not extend into the The flexure area anterior to the distal end of the metatarsal. The outer adjustment part has relatively high pressure resistance. The sole assembly may further include a forefoot anchorage portion beneath the distal end of the fifth metatarsal. The fixed part of the forefoot has relatively little pressure resistance. In some embodiments, the sole assembly may also include a medial adjustment portion extending from the heel through the arch along the medial side of the assembly.

Owner:WOLVERINE OUTDOORS

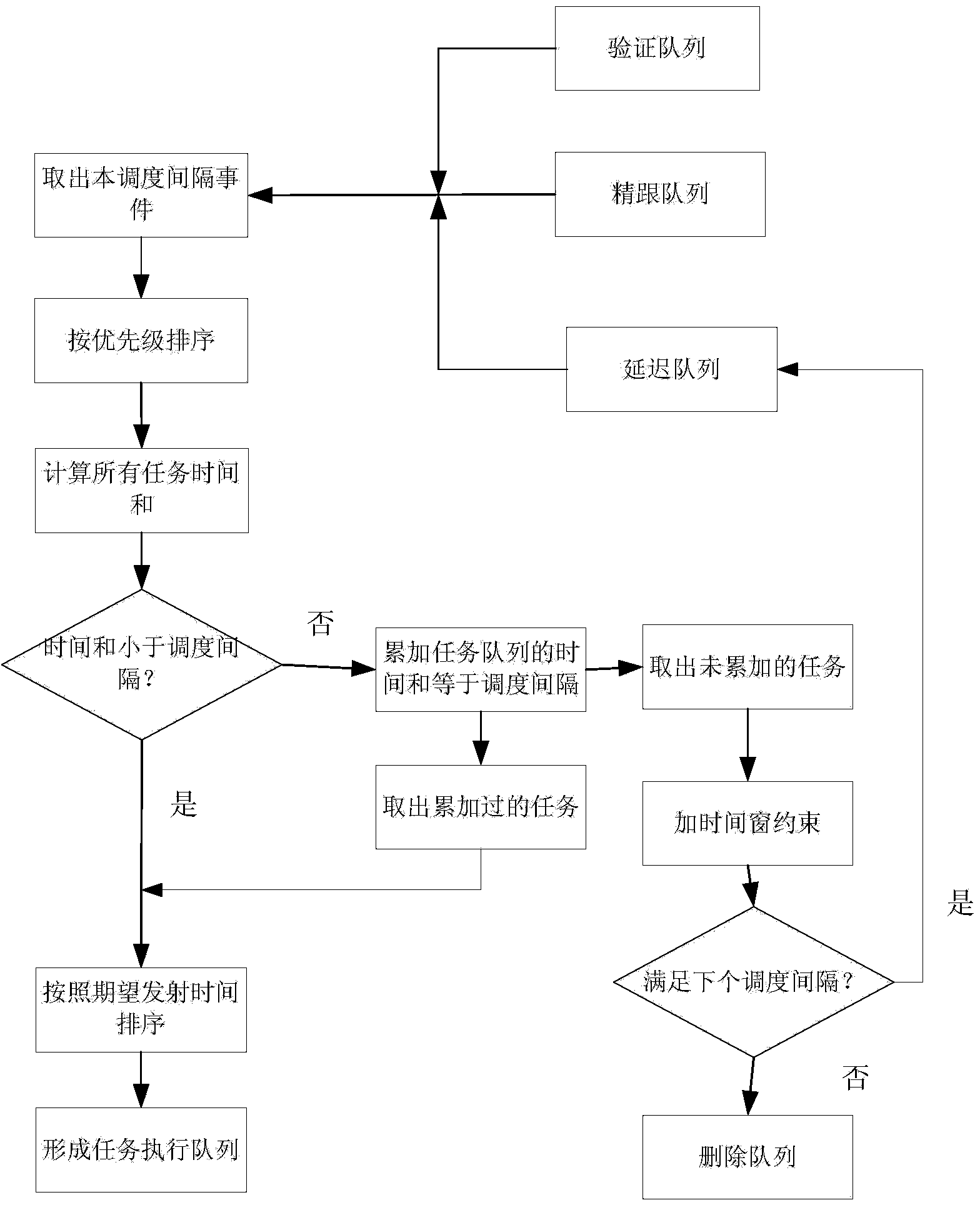

Method for implementing rotating phased array radar beam self-adaption arrangement based on twice sorting

InactiveCN104076333AReduce the probability of driftSmall time offsetRadio wave reradiation/reflectionElevation angleSelf adaptive

The invention relates to a twice-sorting self-adaption arrangement algorithm for two-dimensional rotating phased array radar beam dwelling, in particular to a method for implementing rotating phased array radar beam self-adaption arrangement based on twice sorting. The method is mainly suitable for beam dwelling task arrangement of rotating phased array radar. Each dwelling task has the following attributes including the priority, the dwelling time, the expected execution moment, the time window, the actual execution moment, the direction and the elevation angle. The first-time sorting of the twice sorting method is achieved through the steps of sorting the dwelling tasks according to the priority, and taking out the tasks, capable of being executed in this interval, according to the dwelling time of the tasks when limited by the scheduling interval which is generally 50 milliseconds or 100 milliseconds. The second-time sorting of the twice sorting method is achieved through the step of sorting the tasks which are taken out according to the sequence of the expected execution moments. The actual execution moment of the first task is set to be the starting moment of this interval, the execution moment of the second task is set to be the ending moment of the first task, and setting is sequentially conducted in this way.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

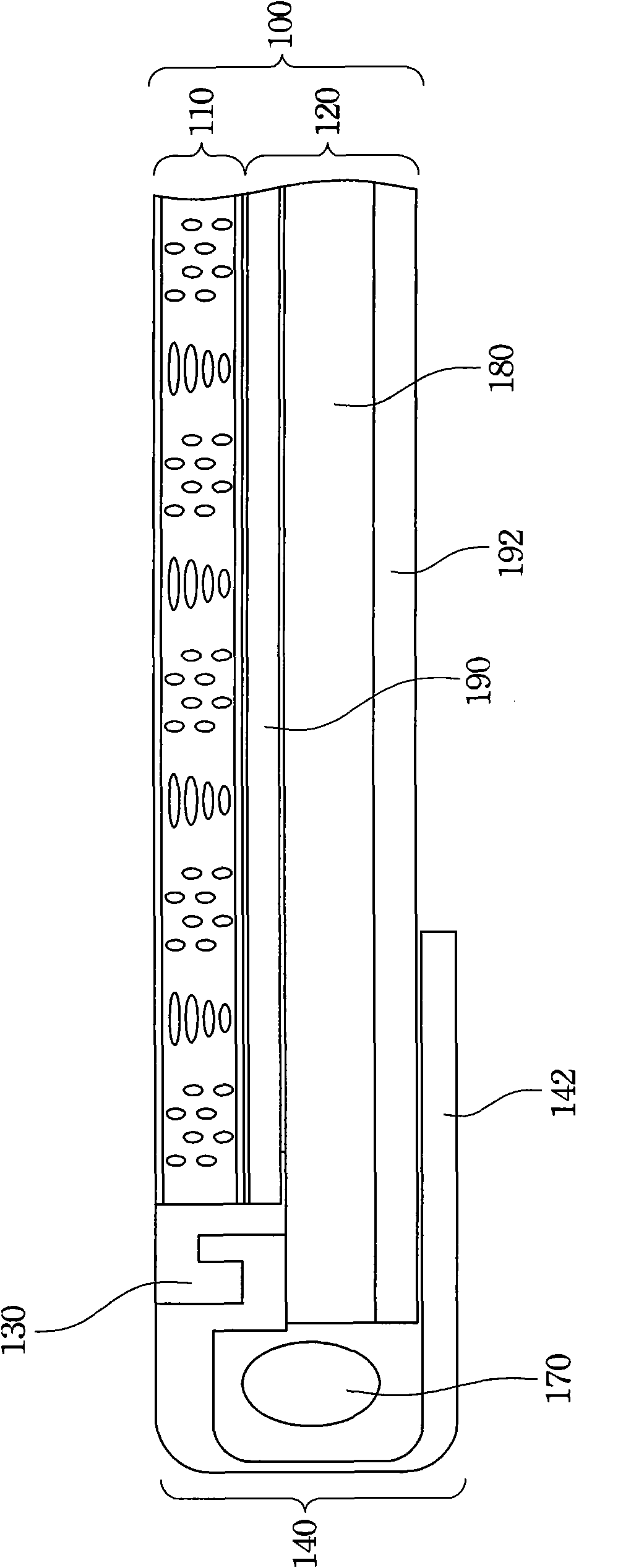

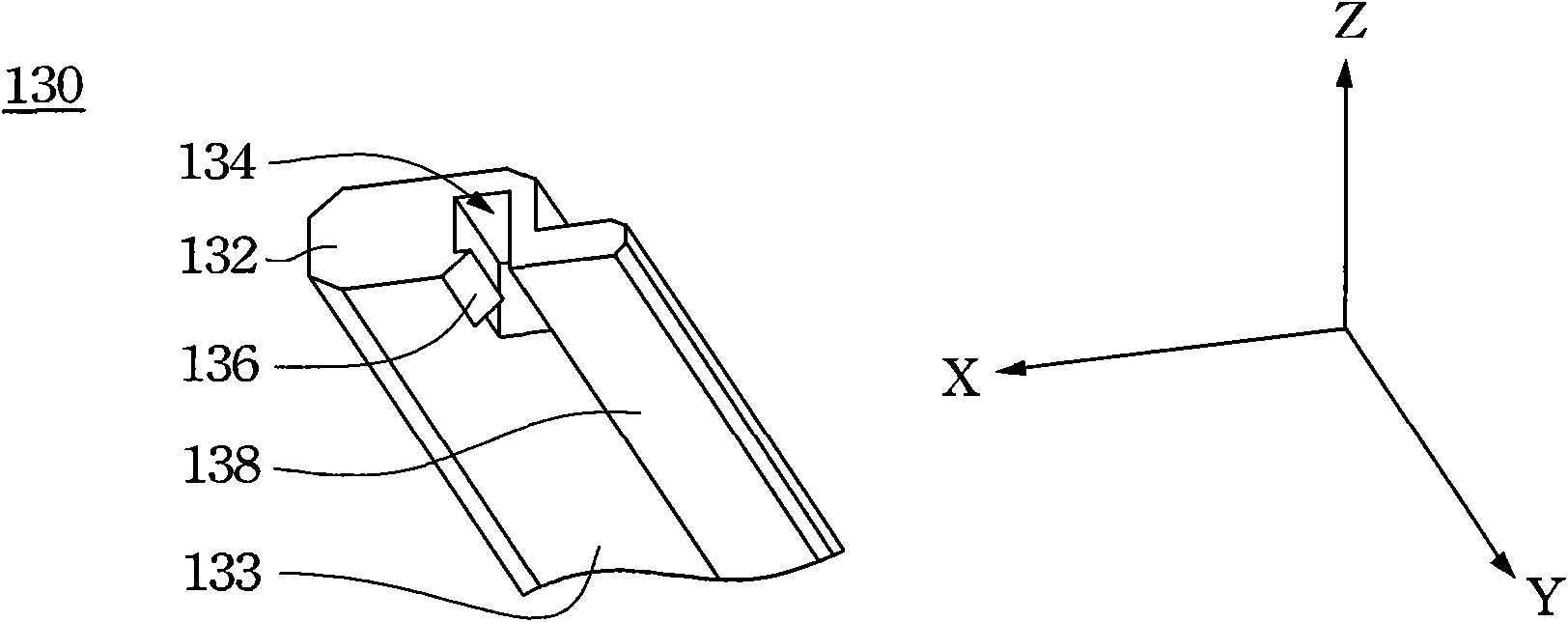

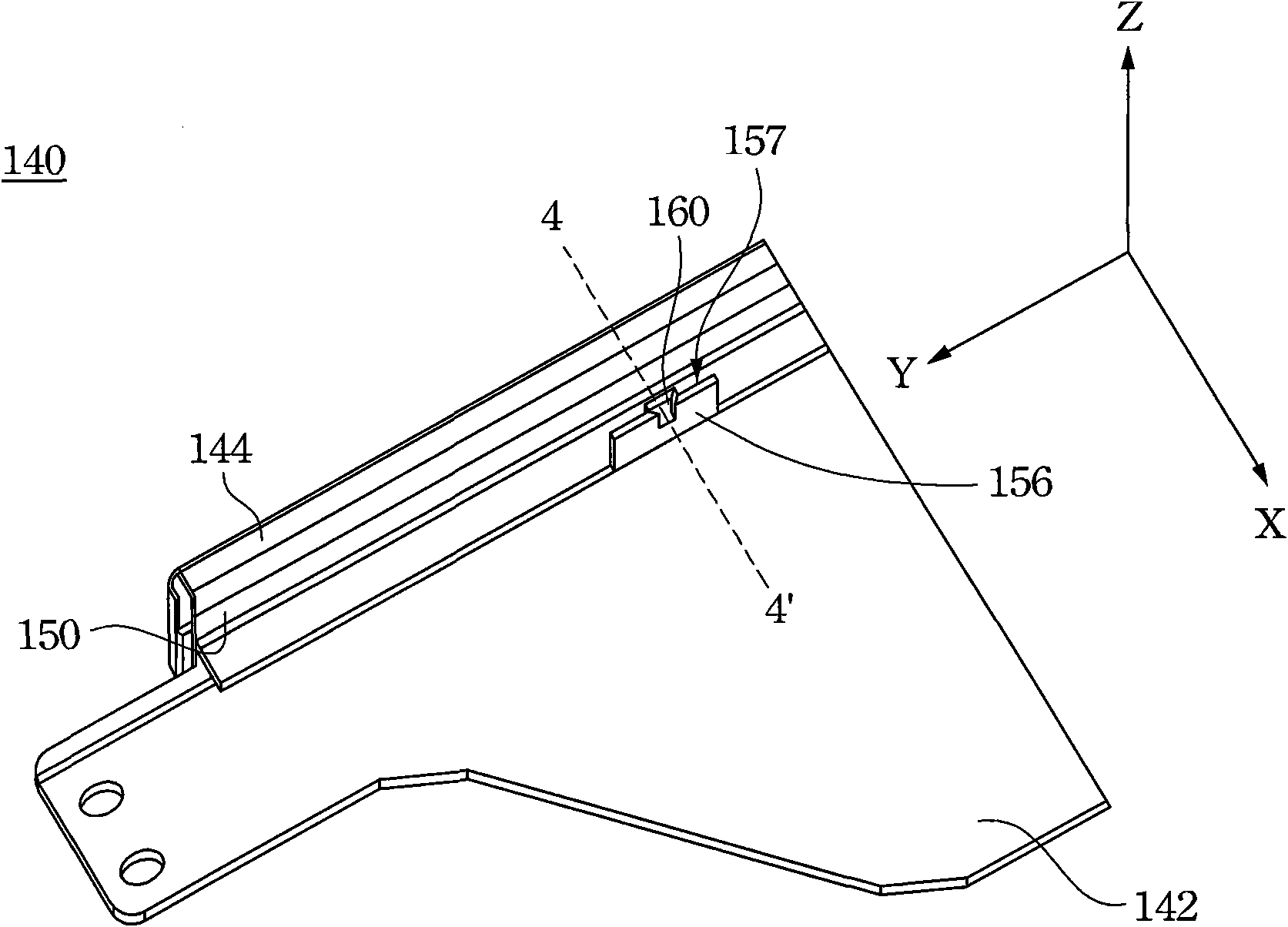

Backlight module and flat-panel display

InactiveCN102032512AReduce rework rateReduce the probability of driftNon-linear opticsLight fasteningsLight guideDisplay device

The invention discloses a backlight module and a flat-panel display. The backlight module comprises a rubber frame, a lamp shade, a lamp source, a light guide plate and a plurality of optical films, wherein the lamp shade comprises a baffle plate and a convex component, the rubber frame is provided with a groove, and the inside of the groove is provided with a clamp component, therefore, when the rubber frame and the lamp shade are assembled, the convex component and the clamp component are mutually buckled. The backlight module disclosed by the embodiment of the invention has the advantages that the lamp shade comprises the baffle plate and the convex component, and the rubber frame is provided with the groove and a convex-component buckling part corresponding to the baffle plate, so that when the rubber frame and the lamp shade are assembled, the baffle plate and the groove are mutually buckled, thereby reducing the horizontal and vertical deviation ratios of the rubber frame. Compared with the current general assembling mode of the rubber frame and the lamp shade, the required reworking rate of the backlight module caused by different appearances and sizes of the backlight module after the rubber frame is assembled can be reduced.

Owner:AU OPTRONICS CORP

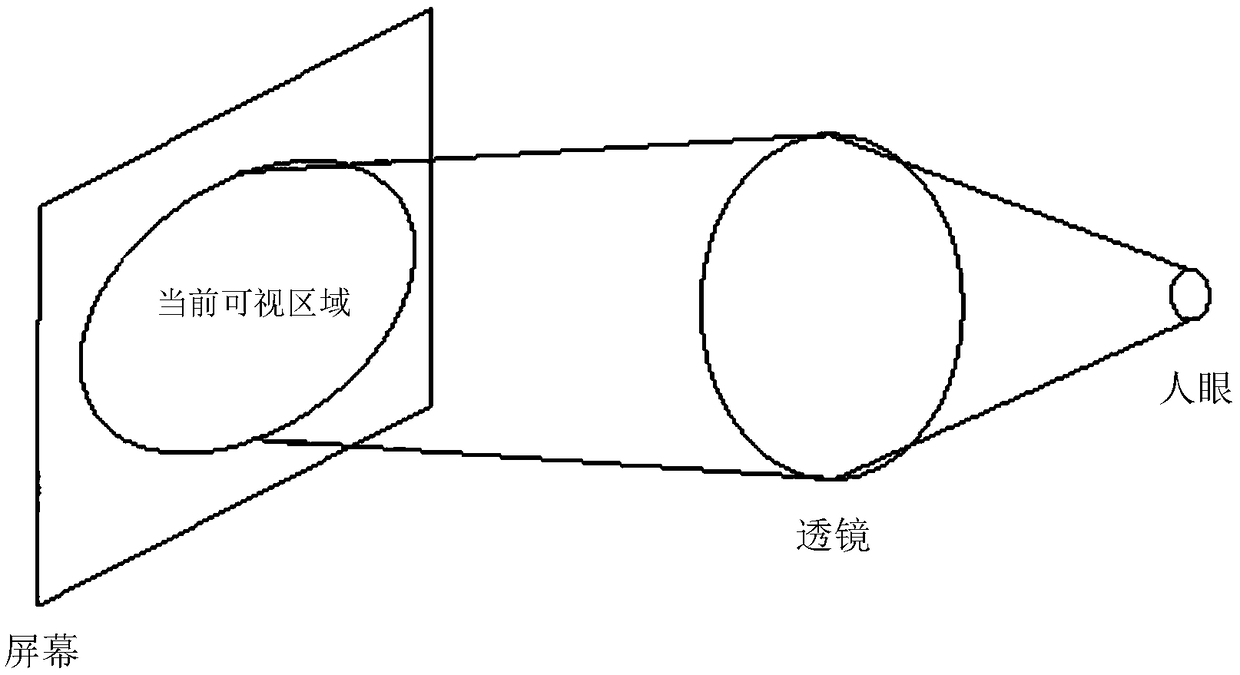

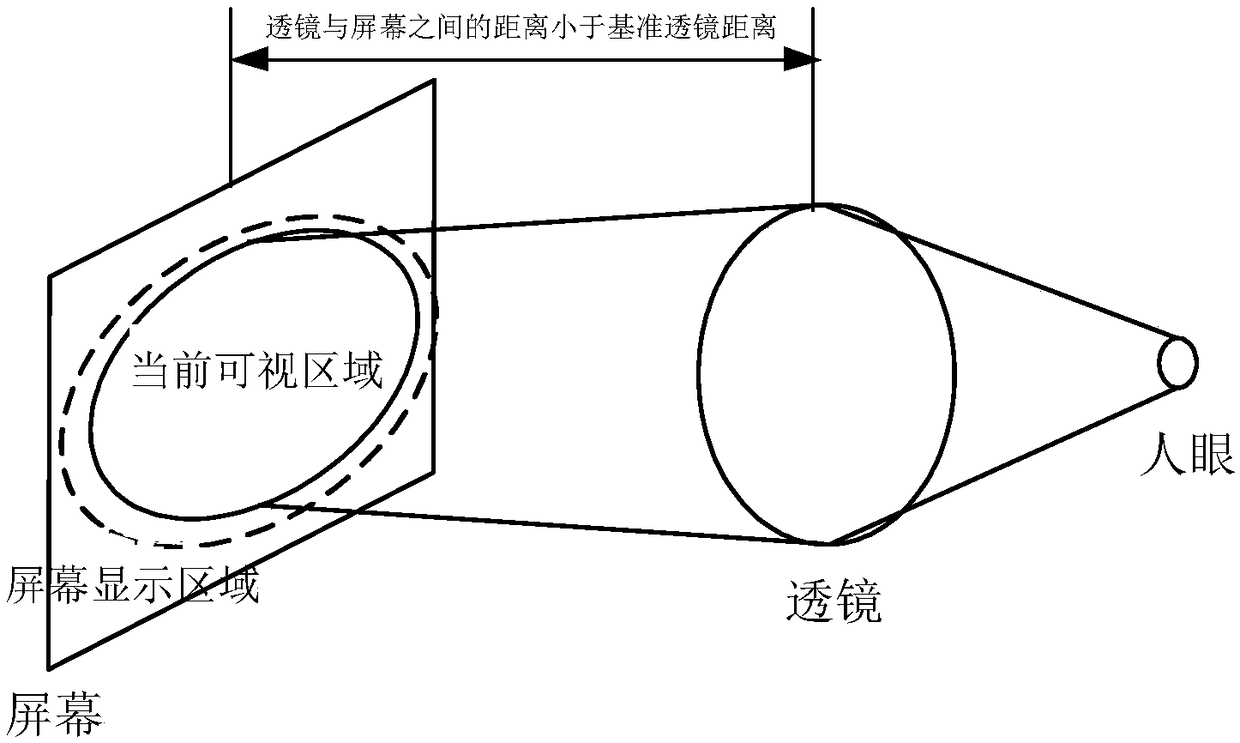

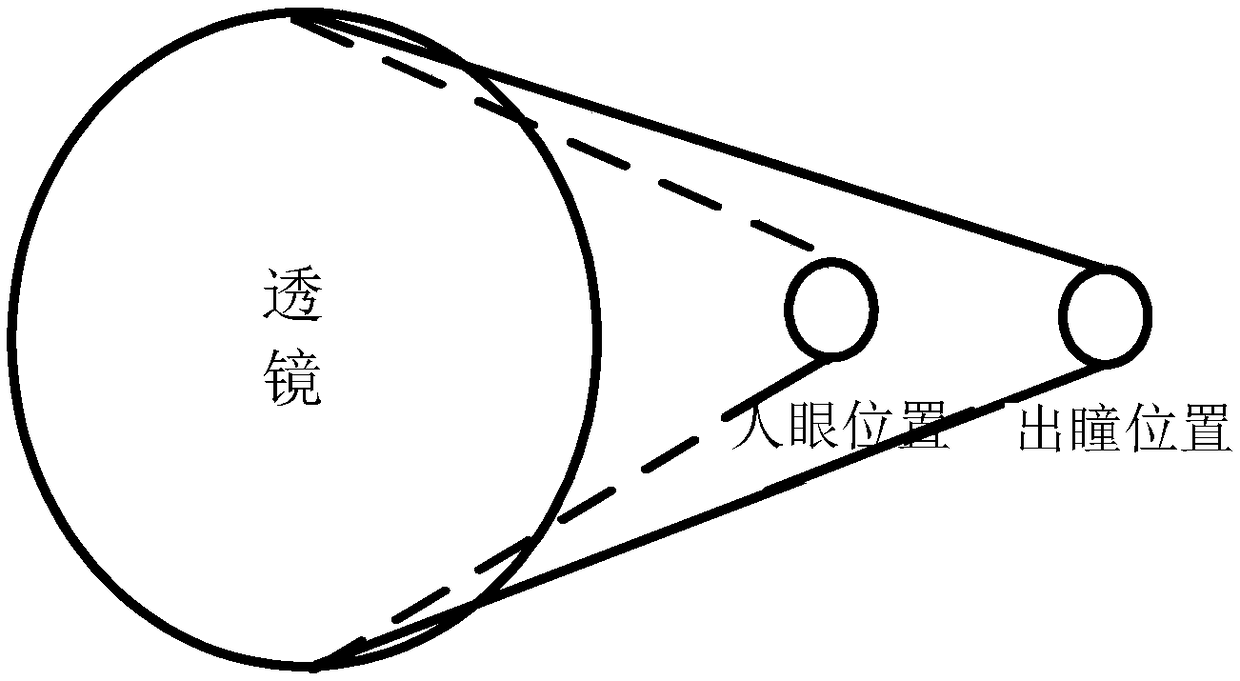

Virtual content display method and device, VR device and medium

ActiveCN109189215AImprove visual effectsReduce the probability of driftInput/output for user-computer interactionGraph readingComputer graphics (images)Self adaptive

The invention discloses a virtual content display method and device, a VR device and a medium, which are applied in the technical field of VR to solve the problem of scene drift in the prior art. Specifically, the method comprises the steps of obtaining the distance between the screen of the VR device and the lens; determining a visible area of the lens on the screen according to the distance, anddetermining a screen display area according to the visible area; acquiring a position of the human eye relative to the lens; determining a user field angle of view corresponding to the position, andadjusting the field angle of view of the virtual content according to the user field angle of view; displaying the virtual content after adjusting the field of view angle on the screen display area. Thus, the adaptive adjustment of the view angle of the screen display area and the virtual content is realized, so that the view angle of the screen display area is consistent with the visible area andthe view angle of the virtual content is consistent with the view angle of the user, thereby effectively reducing the probability of the scene drift occurrence and improving the visual effect of theVR device as much as possible.

Owner:TENCENT TECH (SHENZHEN) CO LTD

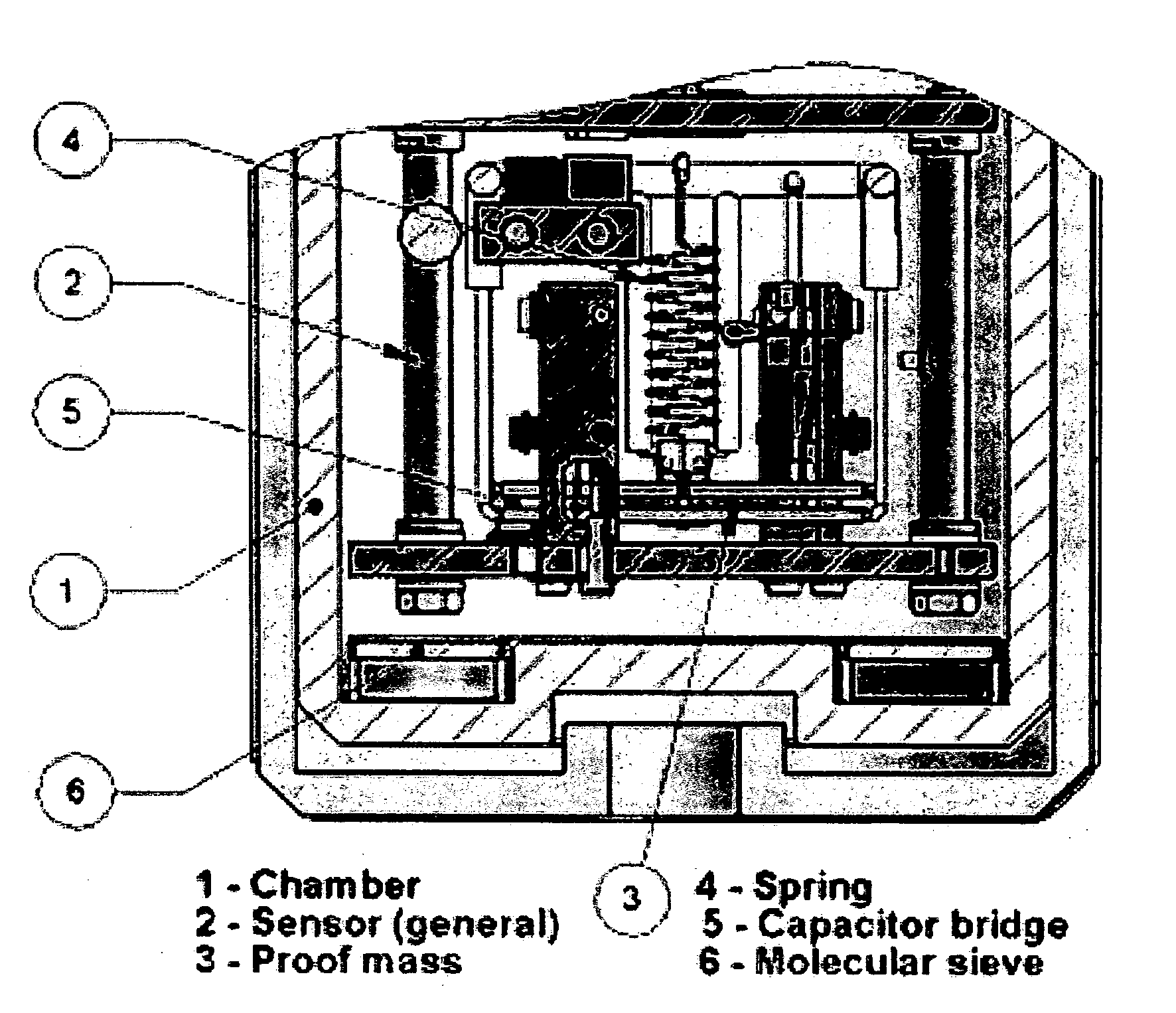

Method of reducing the drift rate of accelerometer and accelerometer with reduced drift rate

InactiveUS20080092653A1Reduce the probability of driftReduce interactionAcceleration measurementSeismologyWater vaporClassical mechanics

An accelerometer comprises a chamber and a proof mass supported by an elastic element within the chamber. The elastic element is formed of fused silica. A sensor senses displacement of the proof mass. Means to inhibit interaction of water vapour with the elastic element is provided.

Owner:SCINTREX LTD

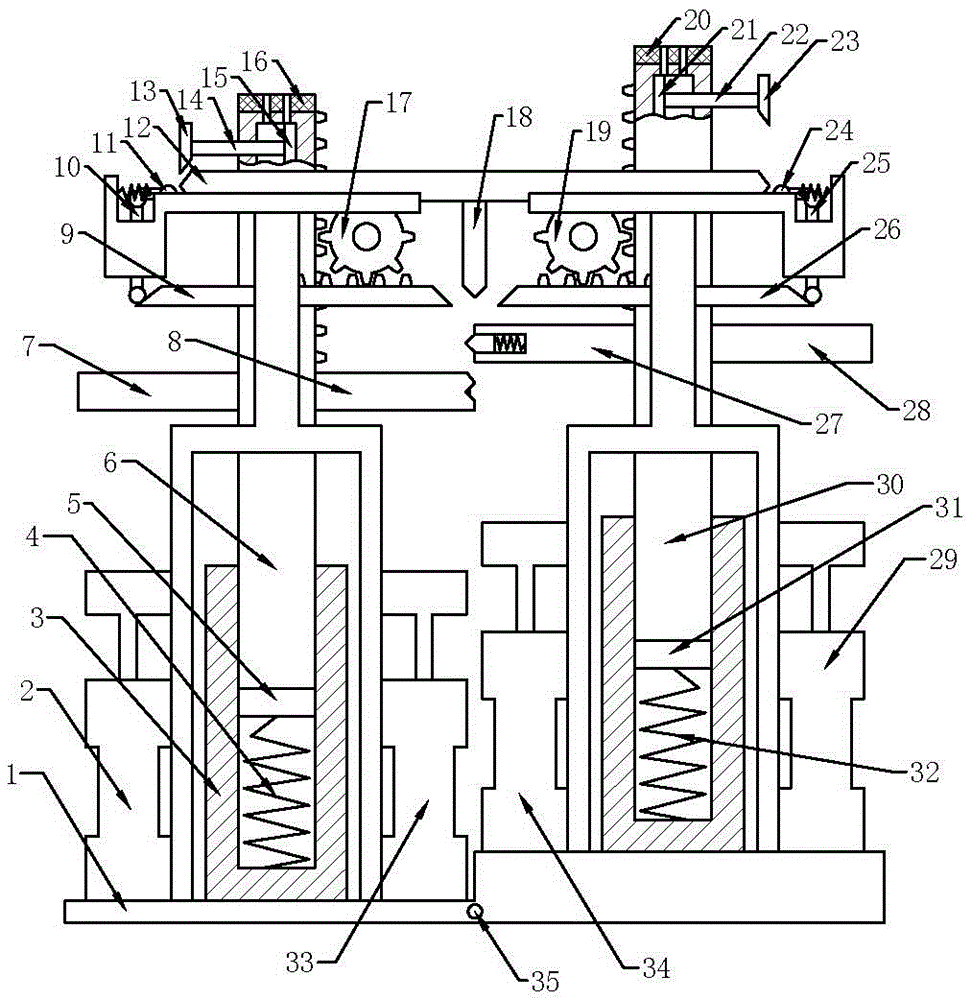

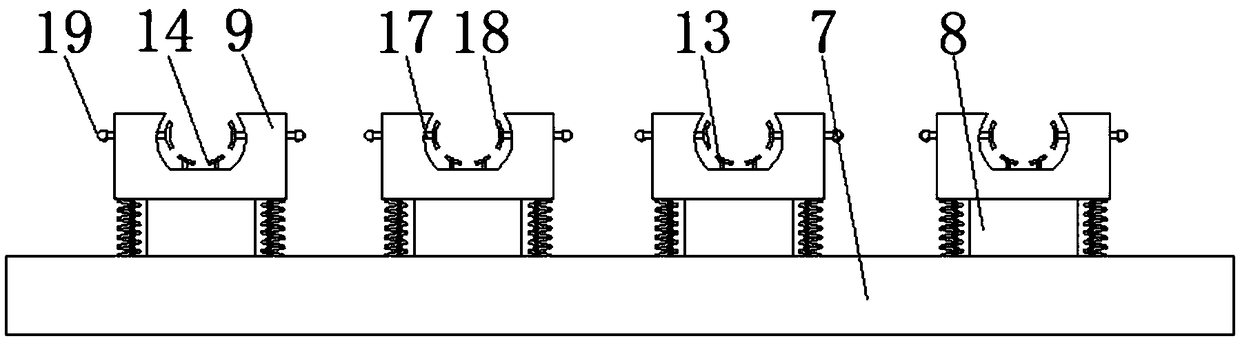

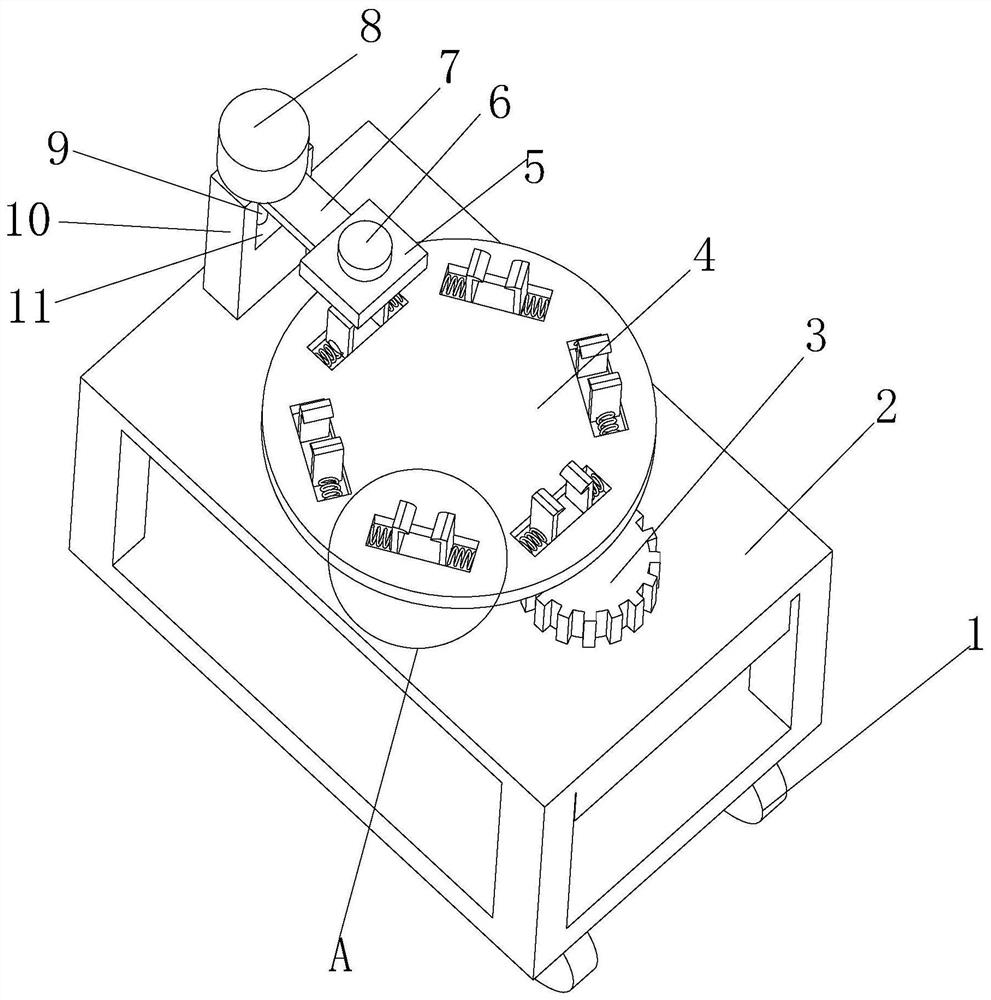

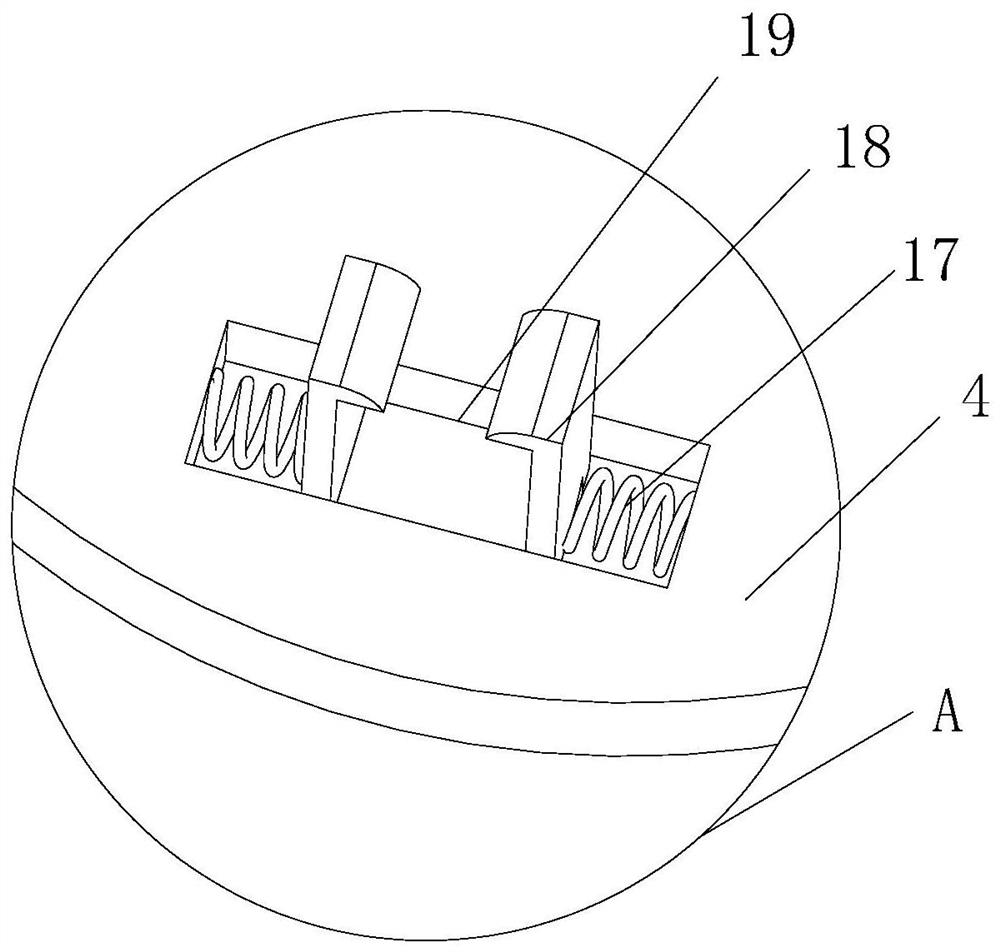

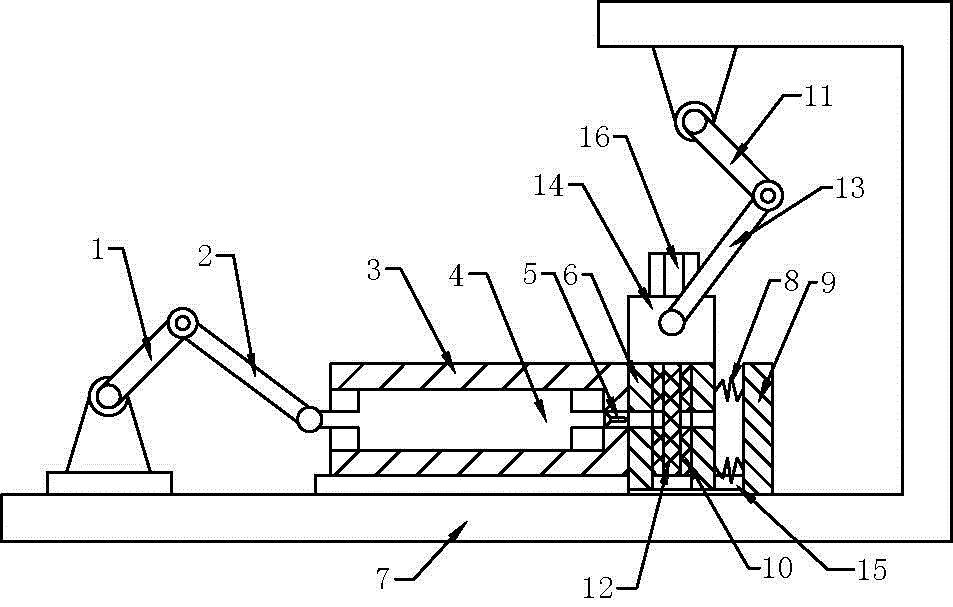

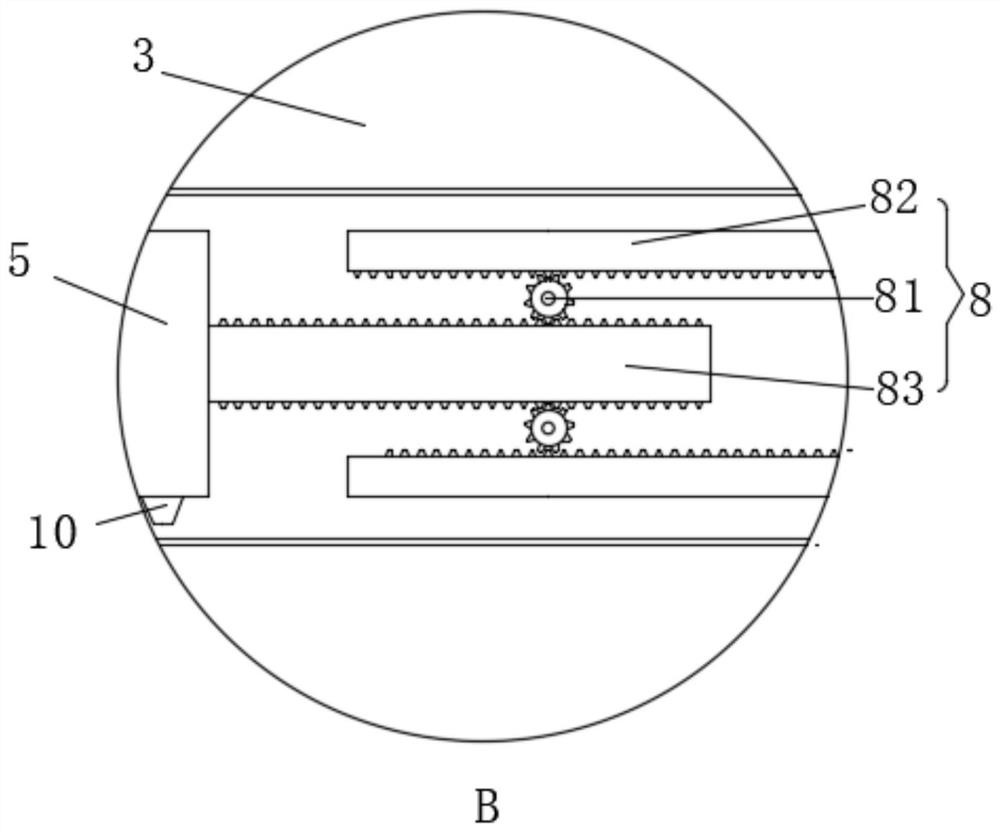

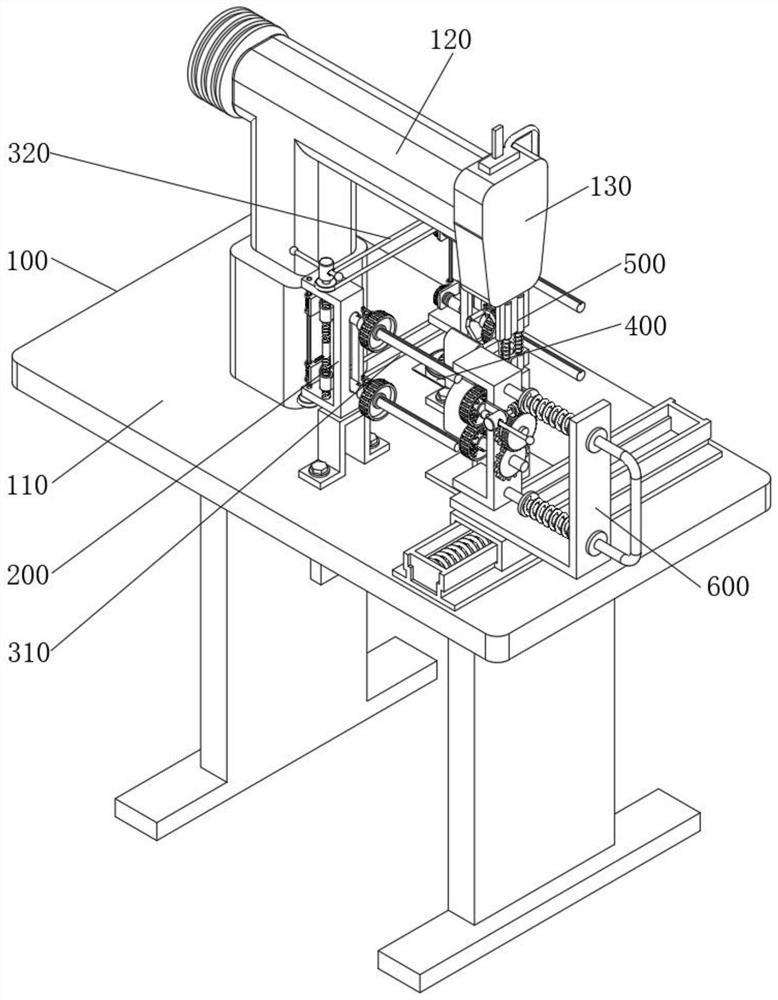

Base for steel plate cutting

InactiveCN106826309AImprove the efficiency of fixing and pressingImprove cut qualityLarge fixed membersPositioning apparatusSheet steelGear wheel

The invention discloses a base for steel plate cutting. The base comprises a frame; the frame is fixedly connected with two sliding cylinders; the sliding cylinders are provided with compression rods, namely a first compression rod and a second compression rod; negative pressure cavities are formed in the two compression rods, and are internally provided with pistons; the pistons are connected with a first wedge plate and a second wedge plate that are arranged at the exteriors of the negative pressure cavities; the first compression rod is engaged to a first gear; the first gear is engaged to a first rack; the first rack abuts against a first wedge rod; the first wedge rod abuts against a second wedge rod; the second compression rod is engaged to a second gear; the second gear is engaged to a second rack; the second rack abuts against a third wedge rod; the third wedge rod abuts against a fourth wedge rod; a fifth wedge rod which abuts against the first wedge plate and the second wedge plate is placed on the frame; the second wedge rod and the fourth wedge rod abut against the fifth wedge rod; the middle part of the fifth wedge rod is fixedly connected with a sixth wedge rod; and the first rack and the second rack abut against the sixth wedge rod. With the adoption of the base for the steel plate cutting, the adjustment efficiency and the cutting quality can be improved.

Owner:YONGCHUAN DISTRICT CHONGQING HUAYI MACHINERY CASTING CO LTD

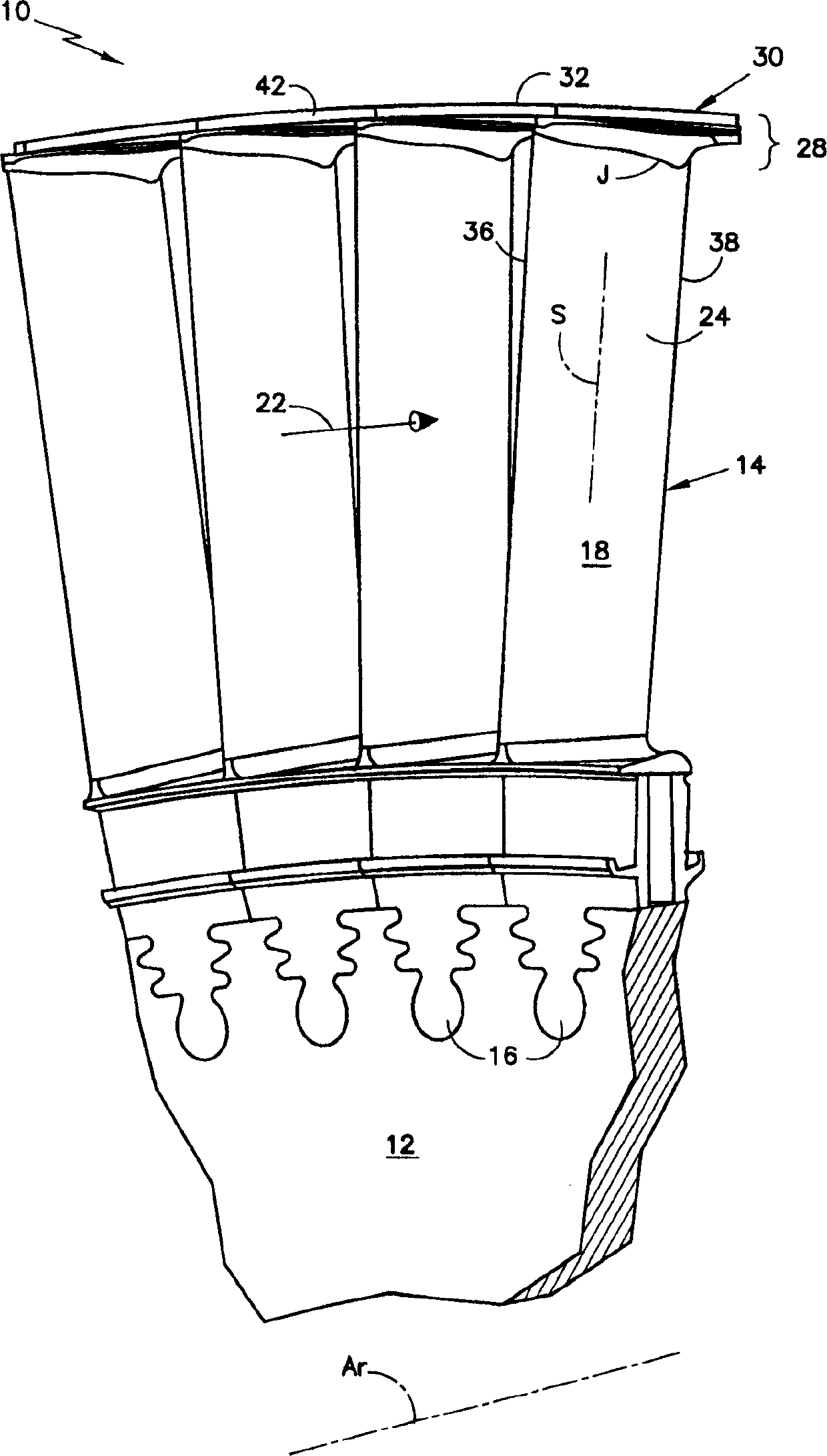

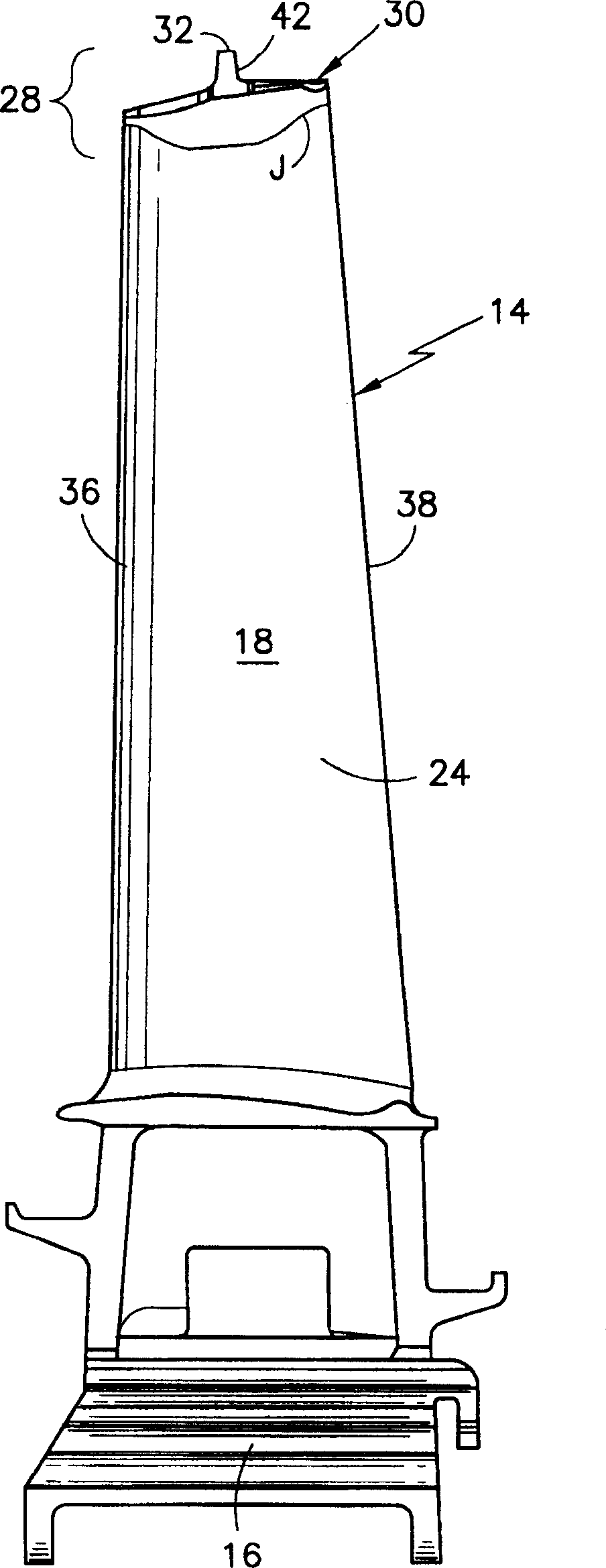

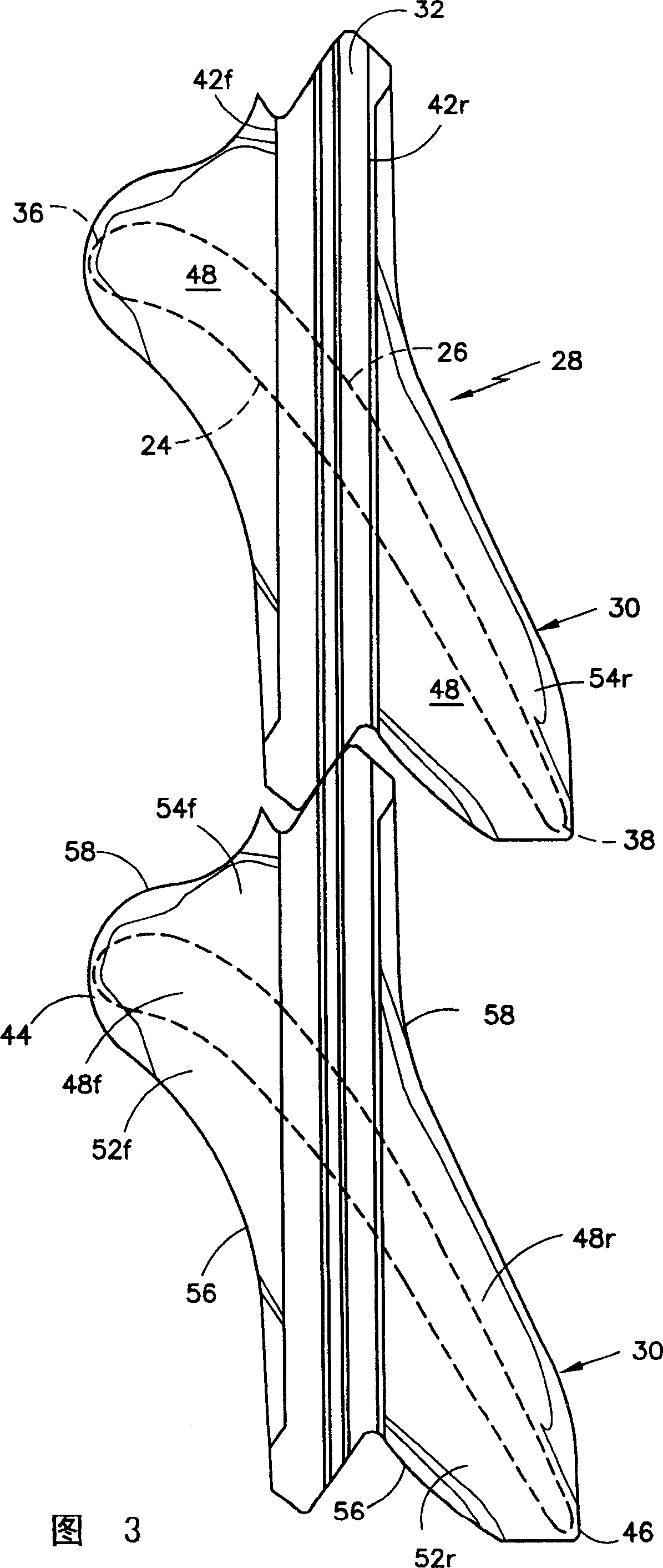

Rotor blade for a rotary machine

InactiveCN1648416AReduce surface stressReduced stress concentration factorEngine manufactureOther chemical processesLeading edgeTrailing edge

A rotor blade (14) having an airfoil (18) and beam construction for a tip shroud (30) is disclosed. Various construction details are developed for providing a transition zone (34) that extend from the sides (26,24) of the airfoil (18) to limit stesses at shroud-airfoil interface, at the disk-root interface and to extend the creep life of the blade while providing a flow path surface of the shroud (30).

Owner:UNITED TECH CORP

Packaging method

ActiveCN109003907AReduce lateral impactReduce the probability of driftSemiconductor/solid-state device manufacturingThermal compressionOptoelectronics

A packaging method includes providing a substrate, wherein a surface to be bonded of the substrate is a first surface to be bonded; providing a plurality of chips, wherein surfaces to be bonded of thechips are second surfaces to be bonded; providing a thin film type packaging materials; forming a bonding layer on at least one of the first surface to be bonded and the second surfaces to be bonded;after forming the bonding layers on at least one of the first surface to be bonded and the second surfaces to be bonded, arranging the first surface to be bonded and the second surfaces to be bondedoppositely and placing the chips on the substrate; after the chip is placed on the substrate, adopting a thermocompression bonding process to realize bonding of the substrate and the plurality of chips through the bonding layer, and filling a packaging material between the chips and the substrate and covering the chip, and using the packaging material after the thermocompression bonding process asa packaging layer. Through the thin film type packaging material, the probability of chip drift in the thermocompression bonding process is reduced, and the yield and reliability of the packaging structure are improved. Moreover, the bonding between the substrate and the chips is realized synchronously by the thermocompression bonding process, and the packaging efficiency is improved.

Owner:NINGBO SEMICON INT CORP

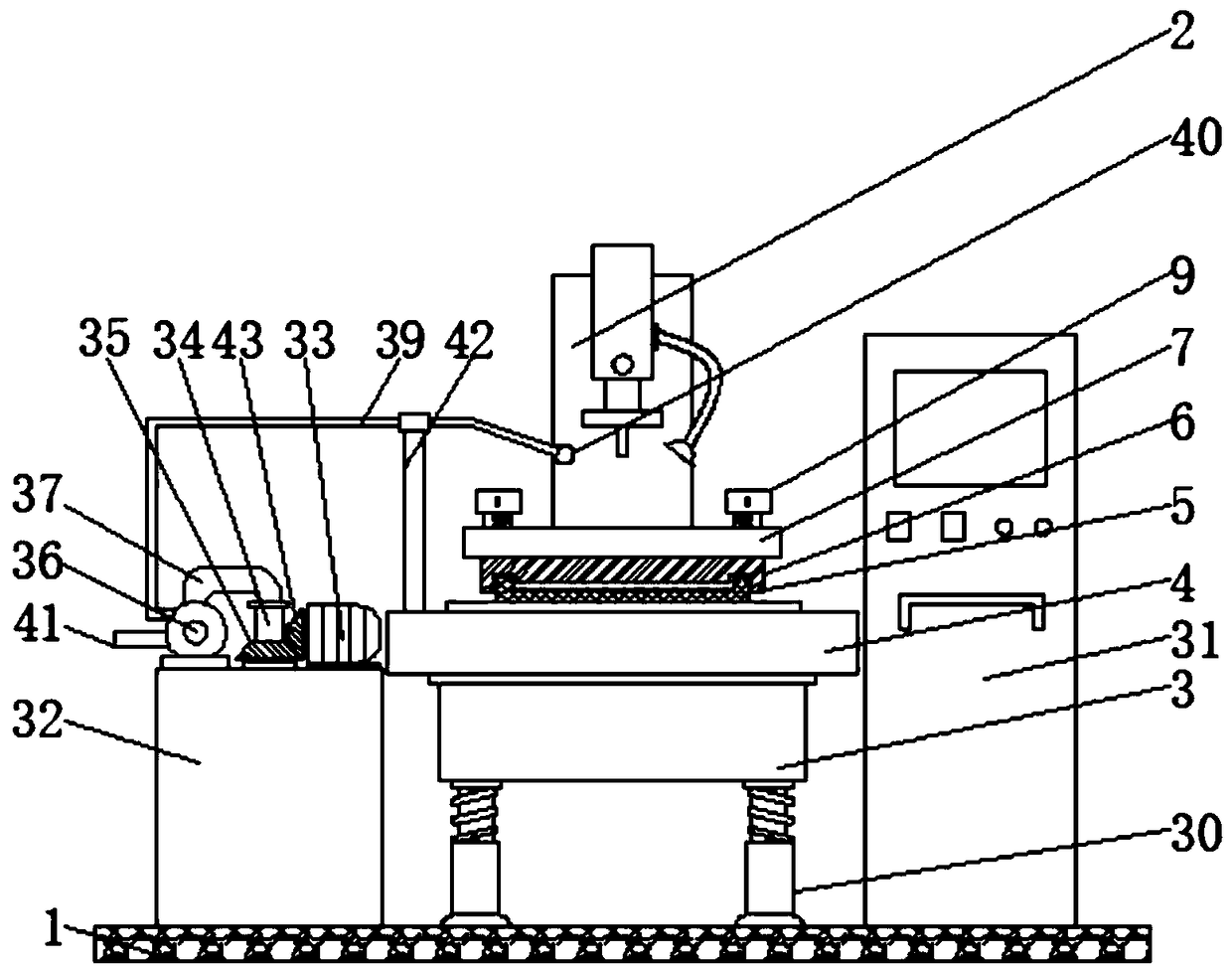

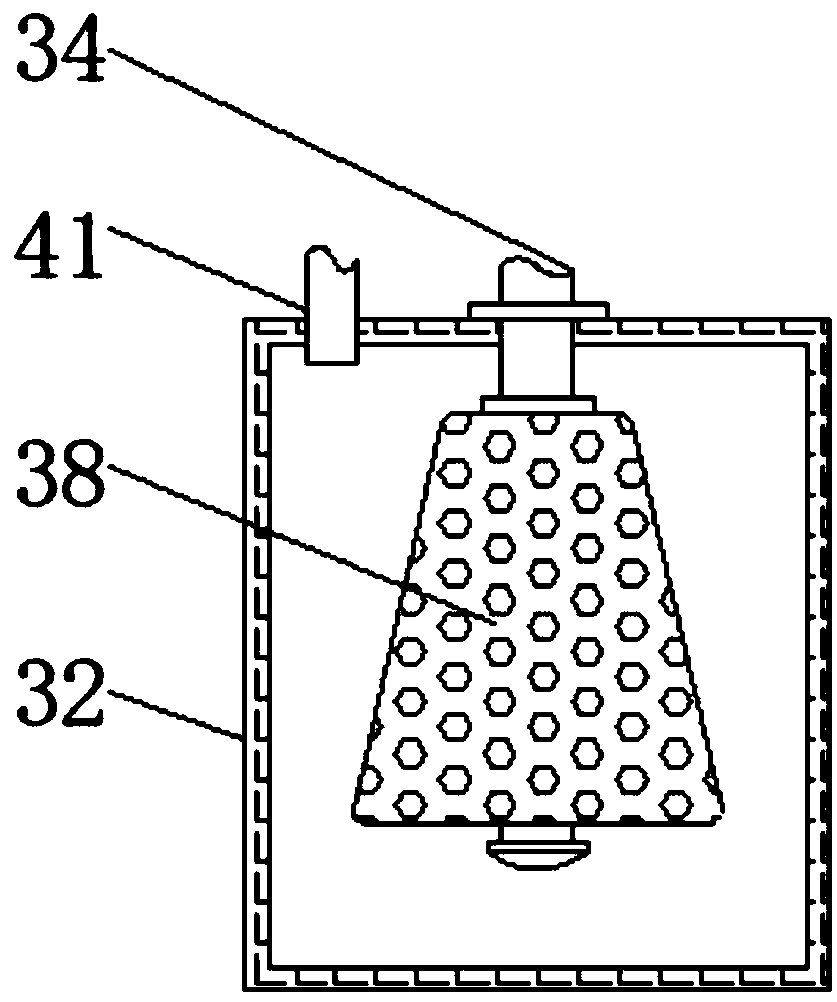

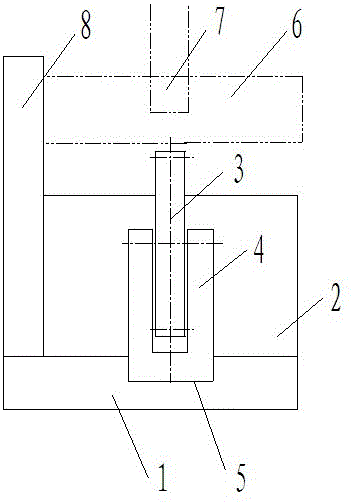

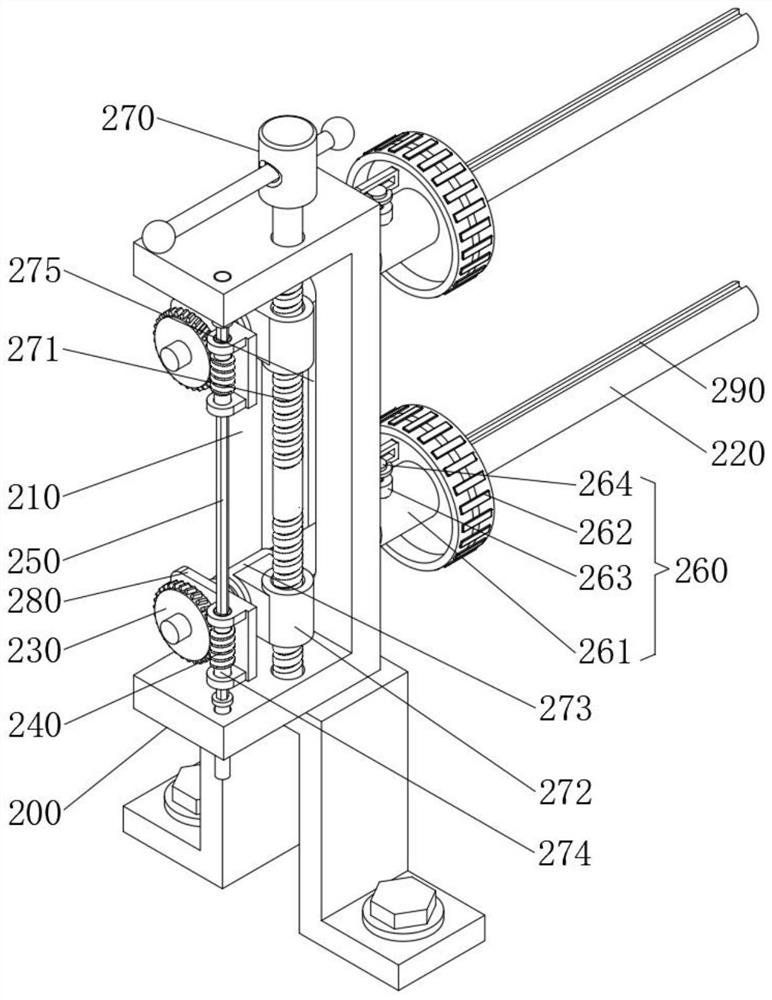

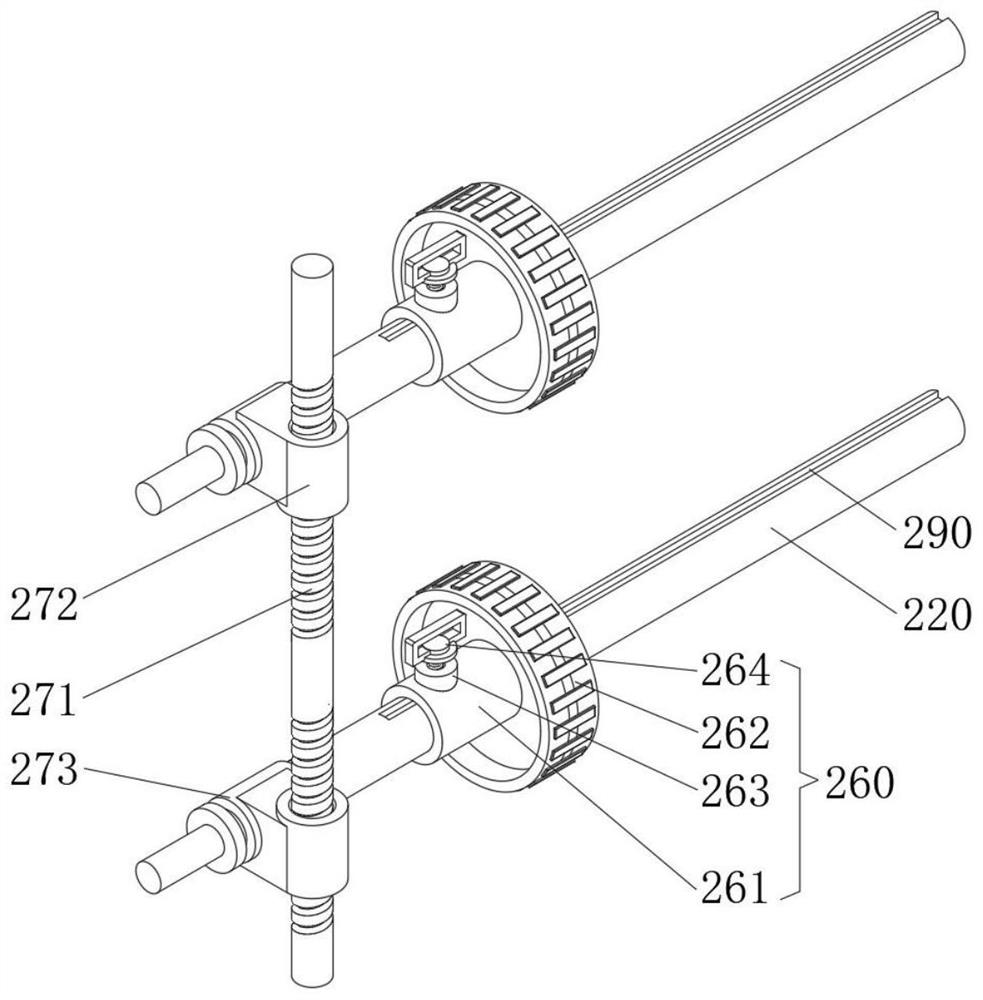

Electric spark cutting machine for stainless steel tube machining

ActiveCN108994406AReduce vibrationReduce noiseElectrical-based auxillary apparatusArchitectural engineeringSlide plate

The invention discloses an electric spark cutting machine for stainless steel tube machining. The machine comprises a bottom plate, a cutting mechanism and a box body, wherein a work table is fixedlyconnected to the top of the box body, a first sliding plate is fixedly connected to the top of the working table, a clamping plate is connected to the top of the first sliding plate in a sliding mode,the top of the clamping plate is fixedly connected with a fixing plate, the top of the fixing plate is movably connected with a fixing block, the top of the fixing block is movably connected with a placing plate, and a movable groove is formed in the bottom of the interior of the placing plate. The machine relates to the technical field of stainless steel tube machining. The electric spark cutting machine for the stainless steel tube machining is characterized in that the fixing plate is fixedly connected to the top of the clamping plate, so that a steel tube can be fixed during cutting, thesteel tube can be cut according to a set cutting line during the cutting, probability of deviation of the steel tube is reduced; the sliding groove is formed in the fixing plate, so that damping of the work table can be realized, vibration generated during the cutting can be reduced, and generated noise can be reduced.

Owner:襄阳福康达机械有限公司

Plastic punching device

InactiveCN105583891AImprove stabilityReduce the probability of driftMetal working apparatusPunchingEngineering

The invention relates to a plastic punching device. The plastic punching device comprises a rack, a punching rod, a sliding groove and two clamping plates. The sliding groove is fixed to the rack. The punching rod is in sliding connection in the sliding groove. A connecting rod is hinged to the left end of the transverse punching rod, a crank is hinged to the connecting rod, and the crank is hinged to the rack. A sliding rail is arranged at the position, located on the right side of the punching rod, of the rack. The two clamping plates are sequentially connected to the sliding rail in a sliding manner from left to right. A first spring is connected between the clamping plate on the right side and the rack. The two clamping plates abut against each other. The clamping plate on the left side is provided with an opening for the sharp end of the punching rod to pass through. A pressing block is arranged above the two clamping plates. A second spring is connected between the pressing block and the rack. The rack is in threaded connection with a pressing rod. The pressing rod is located above the pressing block and abuts against the pressing rod. Compared with the prior art, through cooperation of the pressing block and the two clamping plates, a plastic plate is fixed more stably, and therefore the stability of the plastic plate is improved, and the probability that the sharp end of the punching rod scratches the surface of the plastic plate is reduced.

Owner:CHONGQING HUARUI STANDARD COMPONENT MFG CO LTD

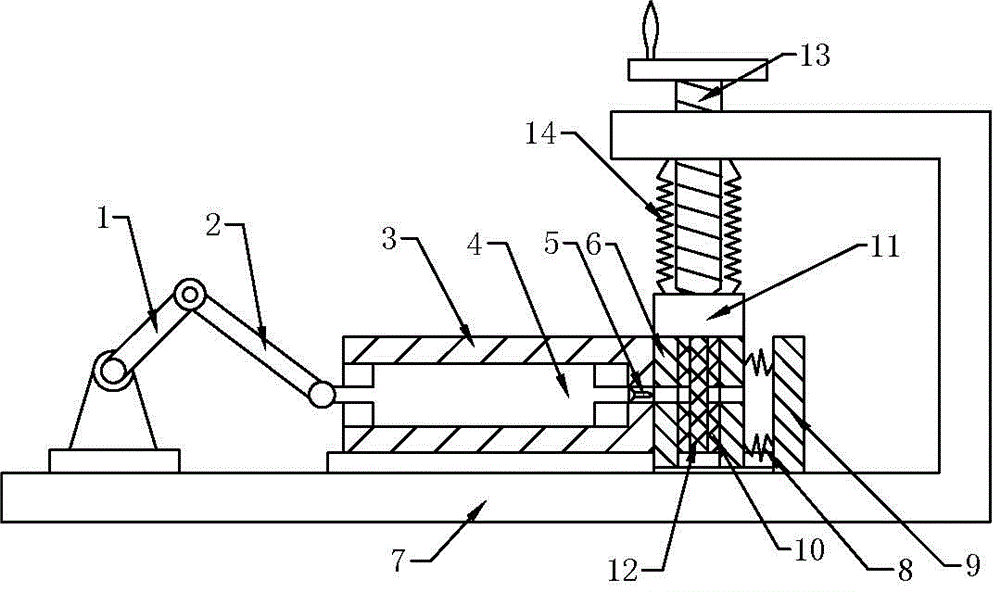

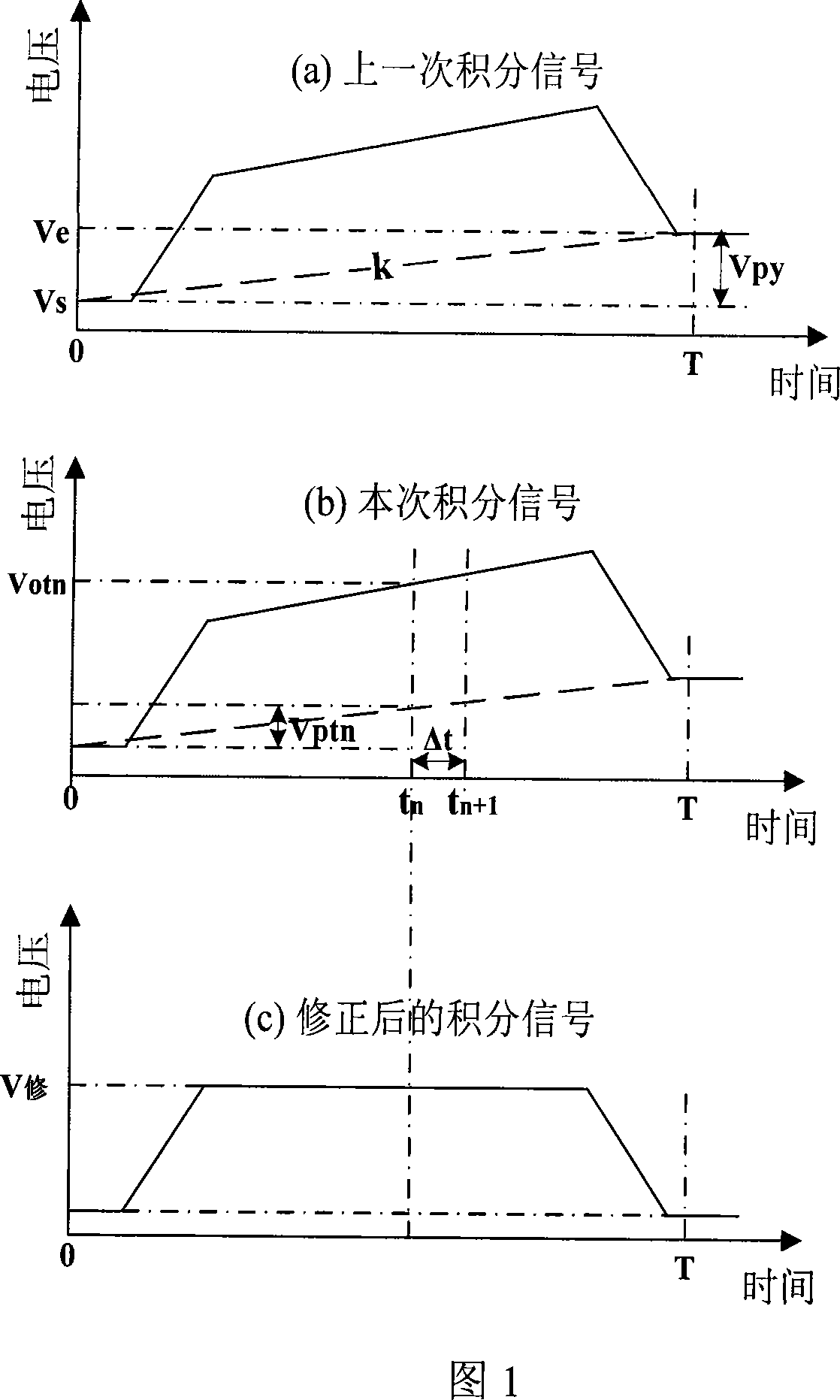

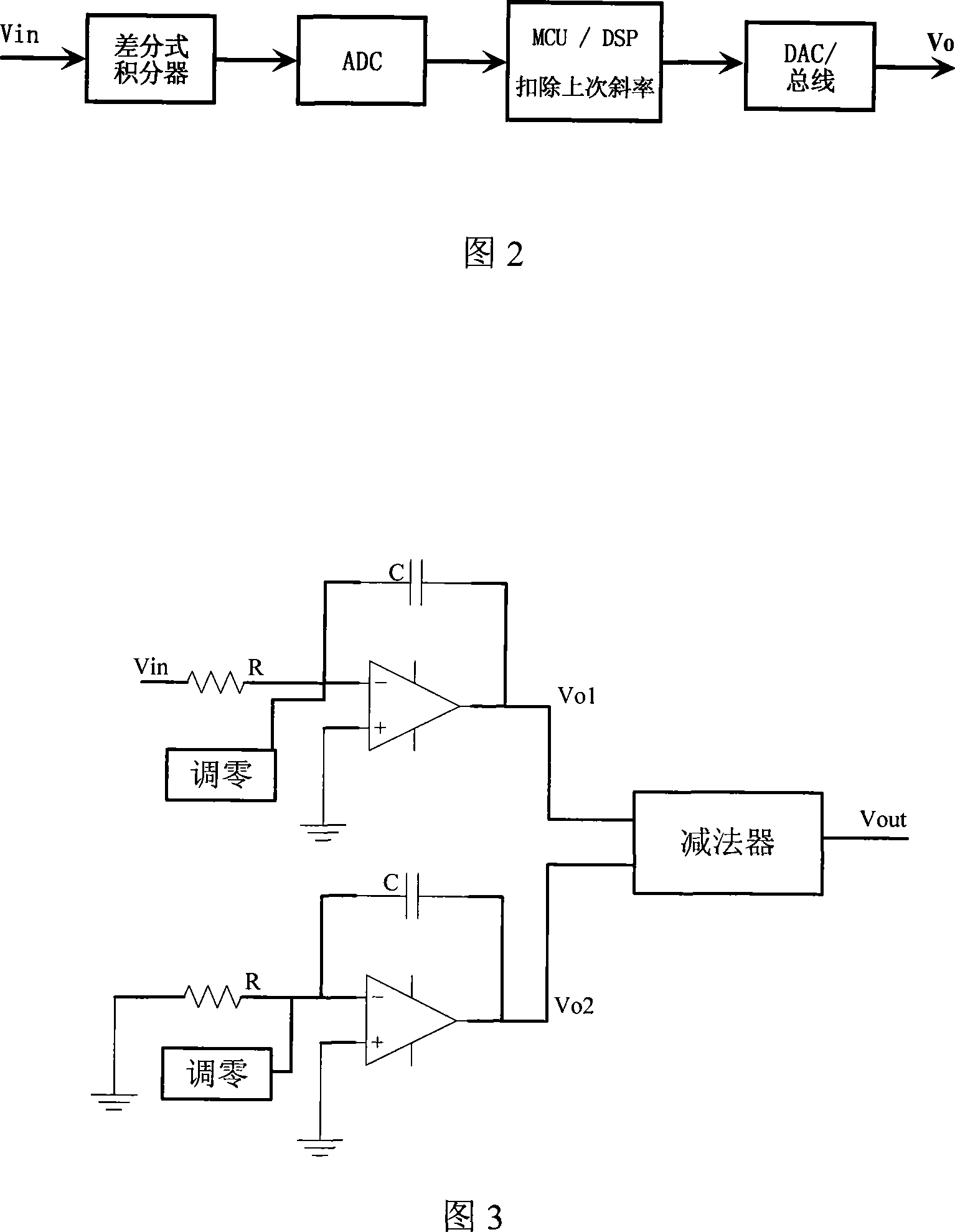

Long time self-adapting integrative approach

InactiveCN101178425AReduce the probability of driftAvoid the hassle of repeatedly zeroingComputing operations for integration/differentiationElectrical testingEngineeringTime integral

The invention relates to a method adapting integral for a long time, which is characterized in that the last pulse signal integral drift rate is tested to calculate the integral excursion amount at any moment of the pulse signal, and to measure a output voltage value of the pulse signal integrating instrument at a corresponding time, thereby obtaining the integral modifying value of the pulse signal at the corresponding time. The method of the invention obtains the automatic modification to null shift for a long time integral by the manner of combining simulated integral and numerical modification.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

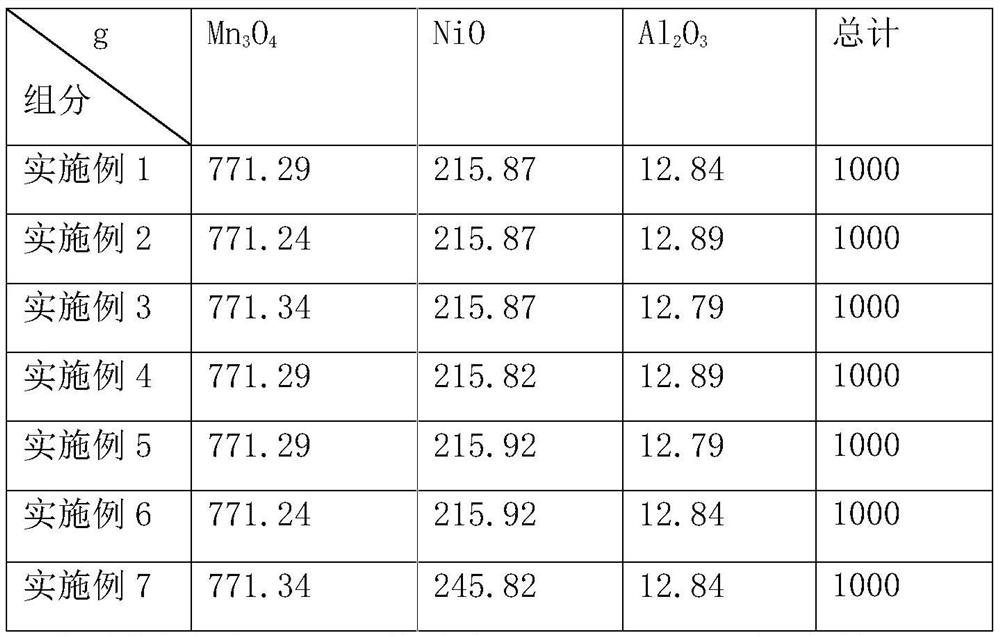

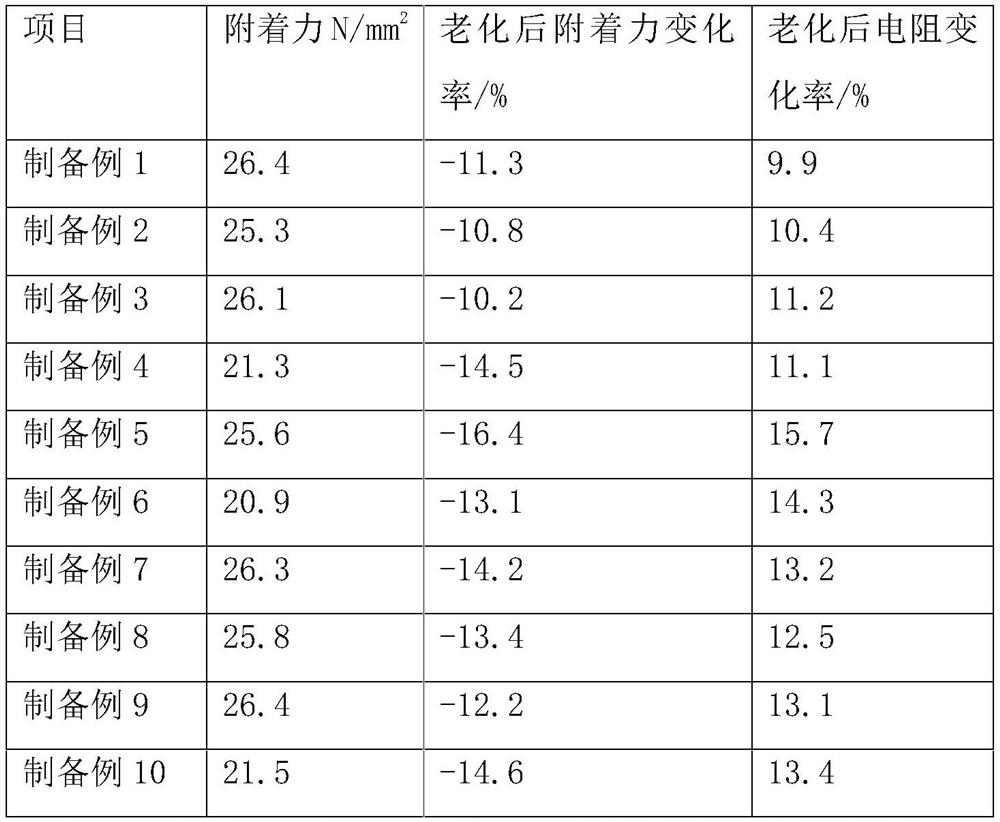

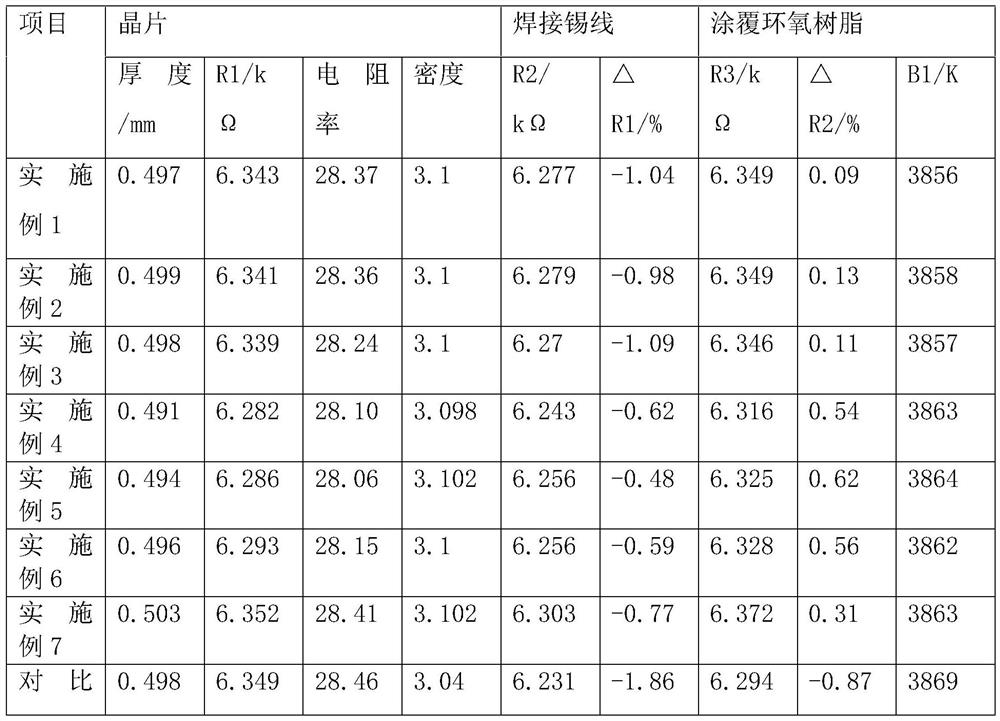

Negative temperature coefficient thermistor chip and preparation method thereof

ActiveCN112479681APrevent resistance drift or even failureExtended service lifeResistor chip manufactureNegative temperature coefficient thermistorsSpray GranulationBreaking strength

The invention relates to the technical field of thermistors, and particularly discloses a negative temperature coefficient thermistor chip and a preparation method thereof. The negative temperature coefficient thermistor chip is prepared from the following raw materials in parts by weight: 771.24-771.34 parts of Mn3O4; 215.82-215. 92 parts of NiO; 12.79-12.89 parts of Al2O3; the preparation methodcomprises the following steps: S1, weighing materials; s2, mixing; s3, calcining; s4, carrying out micro-crushing; s5, carrying out spray granulation; s6, tabletting and forming; s7, pre-sintering; s8, sintering; s9, polishing; s10, brushing silver. The negative temperature coefficient thermistor chip has the advantages that the consistency of the resistance value and the B value is good, the resistance drift rate is smaller than 1% after the thermistor chip is used in a high-temperature environment for a long time, the service life is long, and the stability is high; in addition, the preparation method has the advantages of being high in particle dispersion degree, not prone to agglomeration and high in chip breaking strength.

Owner:青岛三元传感技术有限公司

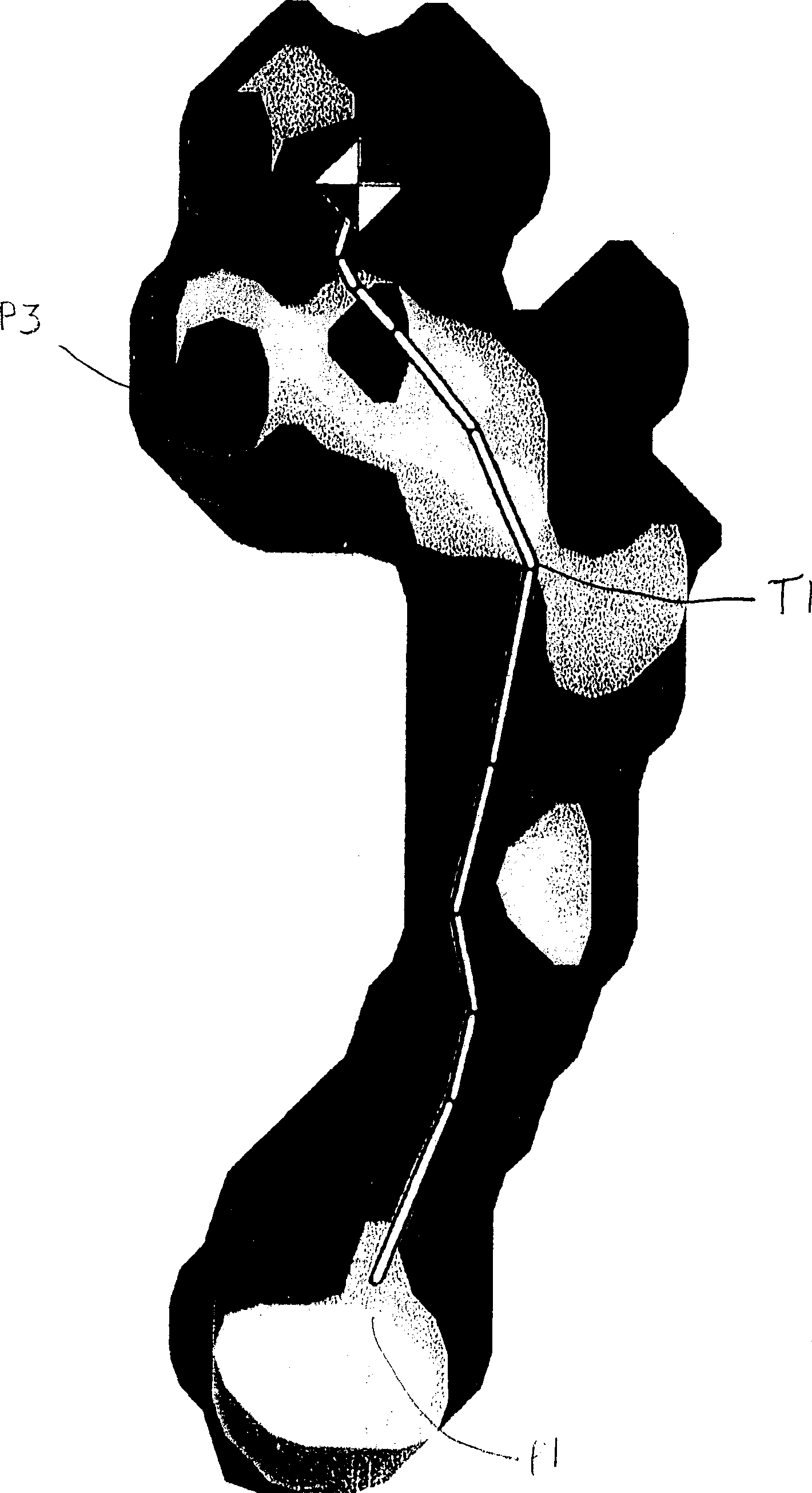

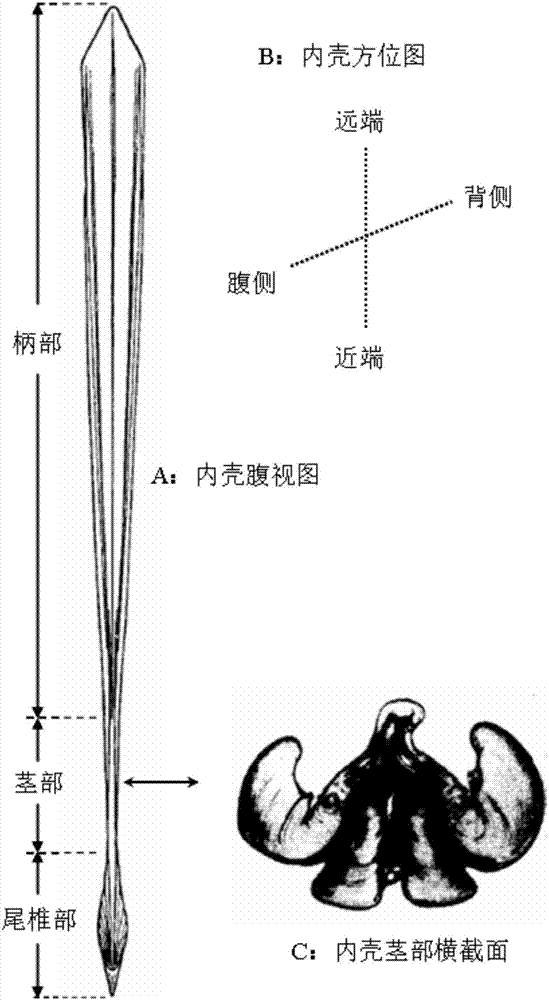

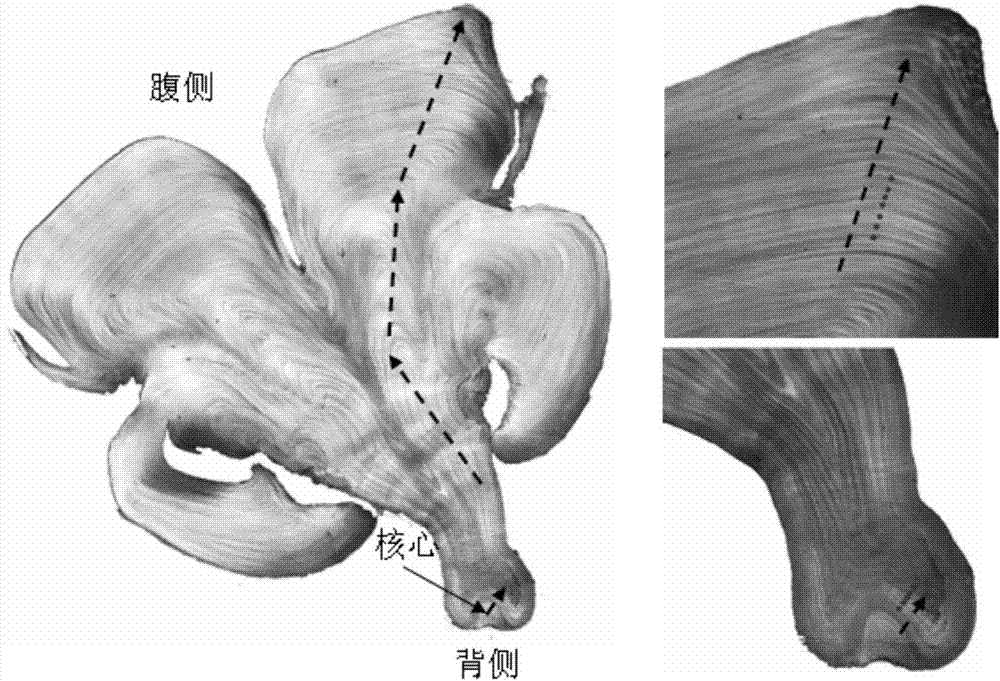

Method for determining age of Ommastrephidae by using inner shell

InactiveCN106970079AEasy extractionEasy to GrindPreparing sample for investigationMaterial analysis by optical meansFisheries scienceResin embedding

The invention specifically relates to a method for determining the age of Ommastrephidae by using an inner shell, belonging to the field of fisheries science. The method comprises grinding of the cross section of the inner shell and observation and counting of growth striations and comprises the following main steps: extraction, cleaning, dehydration, drying, tailoring, resin embedding, cutting, fixation, polishing, burnishing, picture making, counting of growth striations, etc. The method provided by the invention overcomes the problems that the inner shell is difficult to grind, grinding easily leads to shedding and growth striations are hard to observe and count; and the method realizes rapid and accurate grinding to an optimal plane, guarantees high success rate of slice preparation and can accurately determine the number of growth striations.

Owner:SHANGHAI OCEAN UNIV

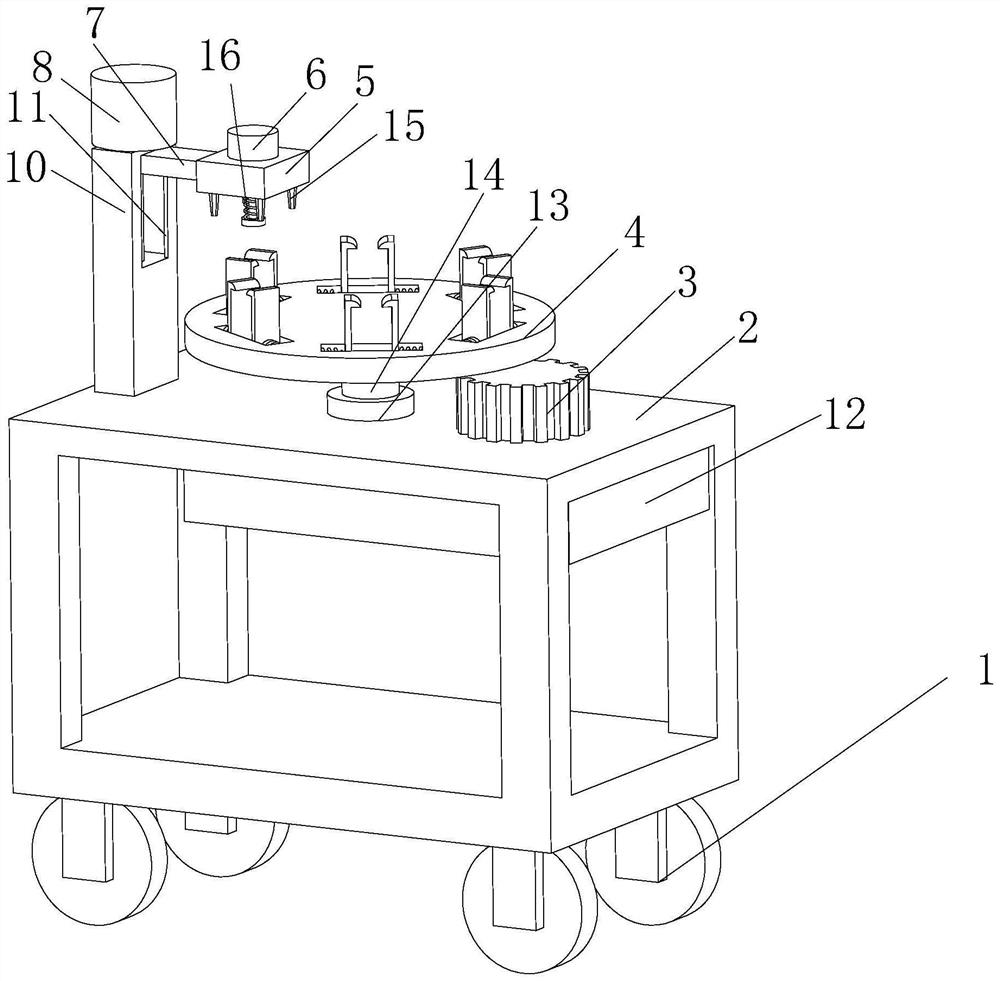

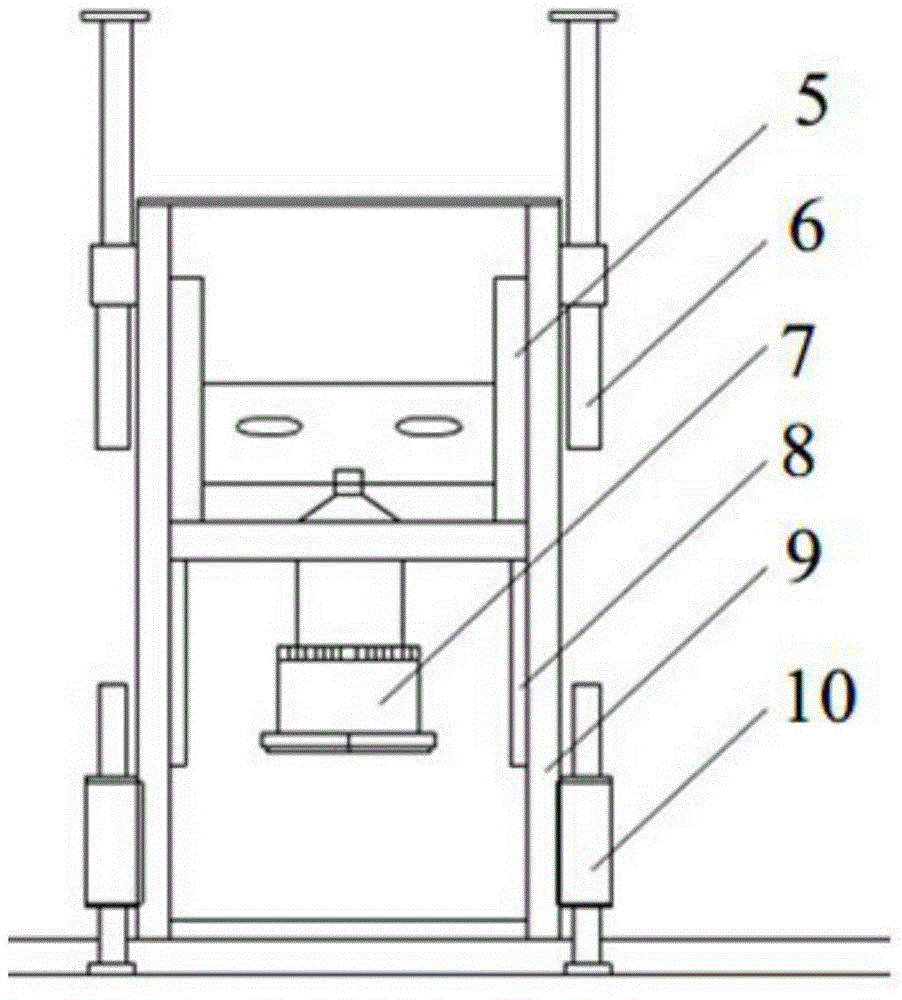

Multi-station automatic assembling device for elevator switch box

Owner:蒙特费罗(湖州)电梯部件有限公司

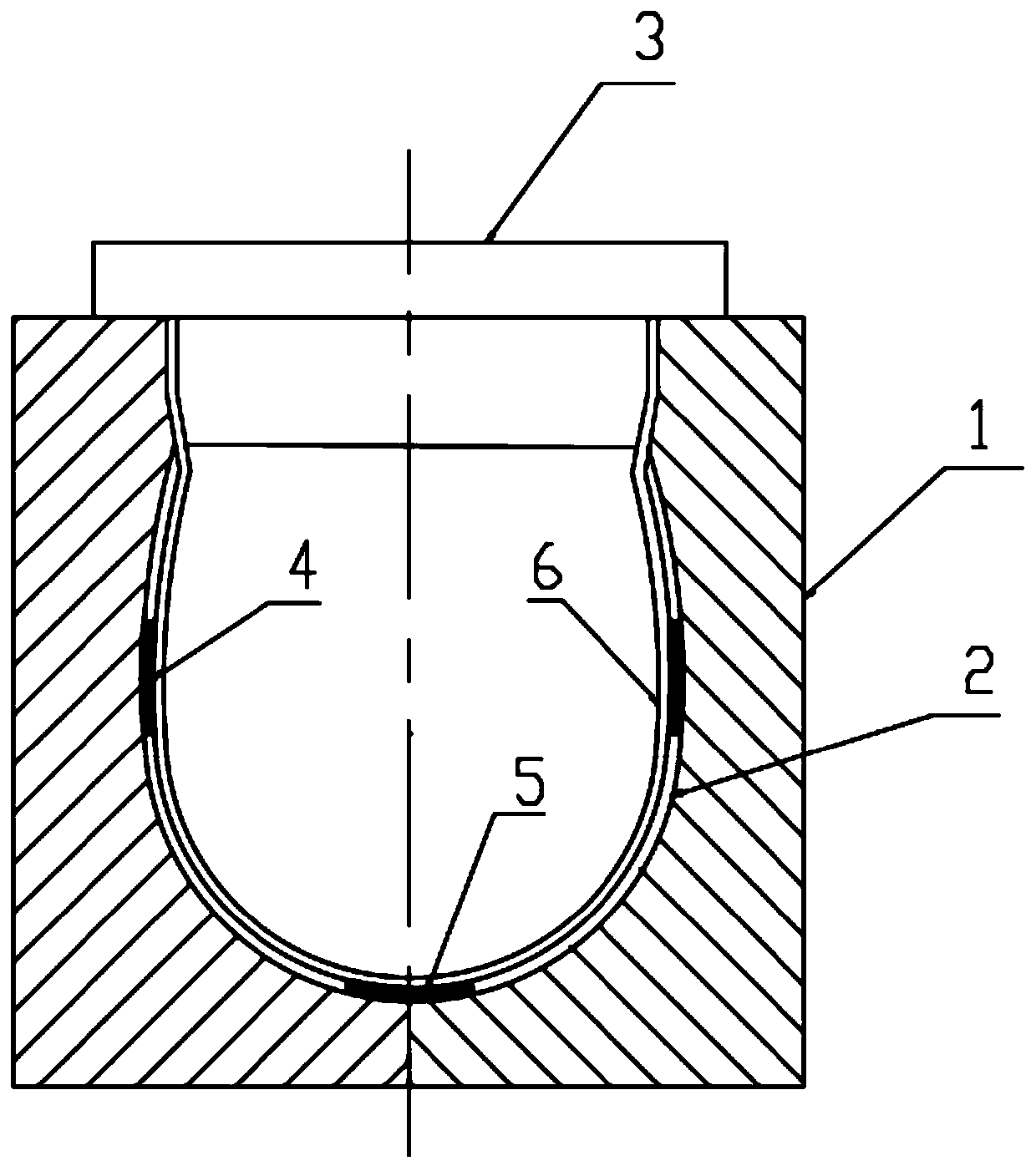

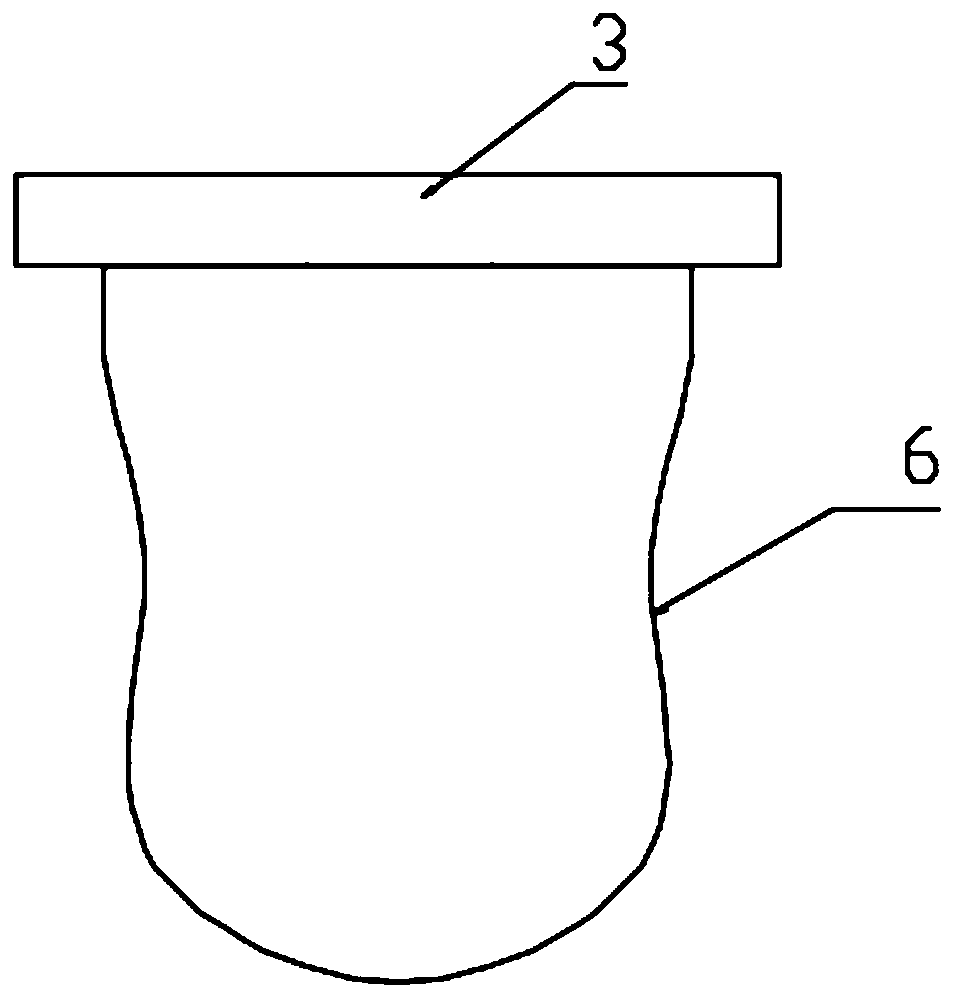

Thin-wall shell forming die device with rigid insertion type solid core male die

PendingCN110014672AHigh positioning accuracyReduce the probability of driftDomestic articlesEngineeringSilica gel

The invention discloses a thin-wall shell forming die device with a rigid insertion type solid core male die. The thin-wall shell forming die device comprises a female die which is divided into at least two oppositely-arranged parts, and the male die is arranged in the female die; a cavity for forming a shell is formed between the outer wall of the male die and the inner wall of the female die; the male mold is of a solid-core silica gel structure; a core shaft hole which is used for being inserted into by a core shaft and is matched with the core shaft in shape is formed in the male mold; anda core shaft hole port is located at the tail end of the male mold. The thin-wall shell forming die device with the rigid insertion type solid core male die can eliminate glue accumulation, ensure uniform wall thickness of the formed shell, and is more convenient and fast to operate.

Owner:厦门宇诠复材科技有限公司

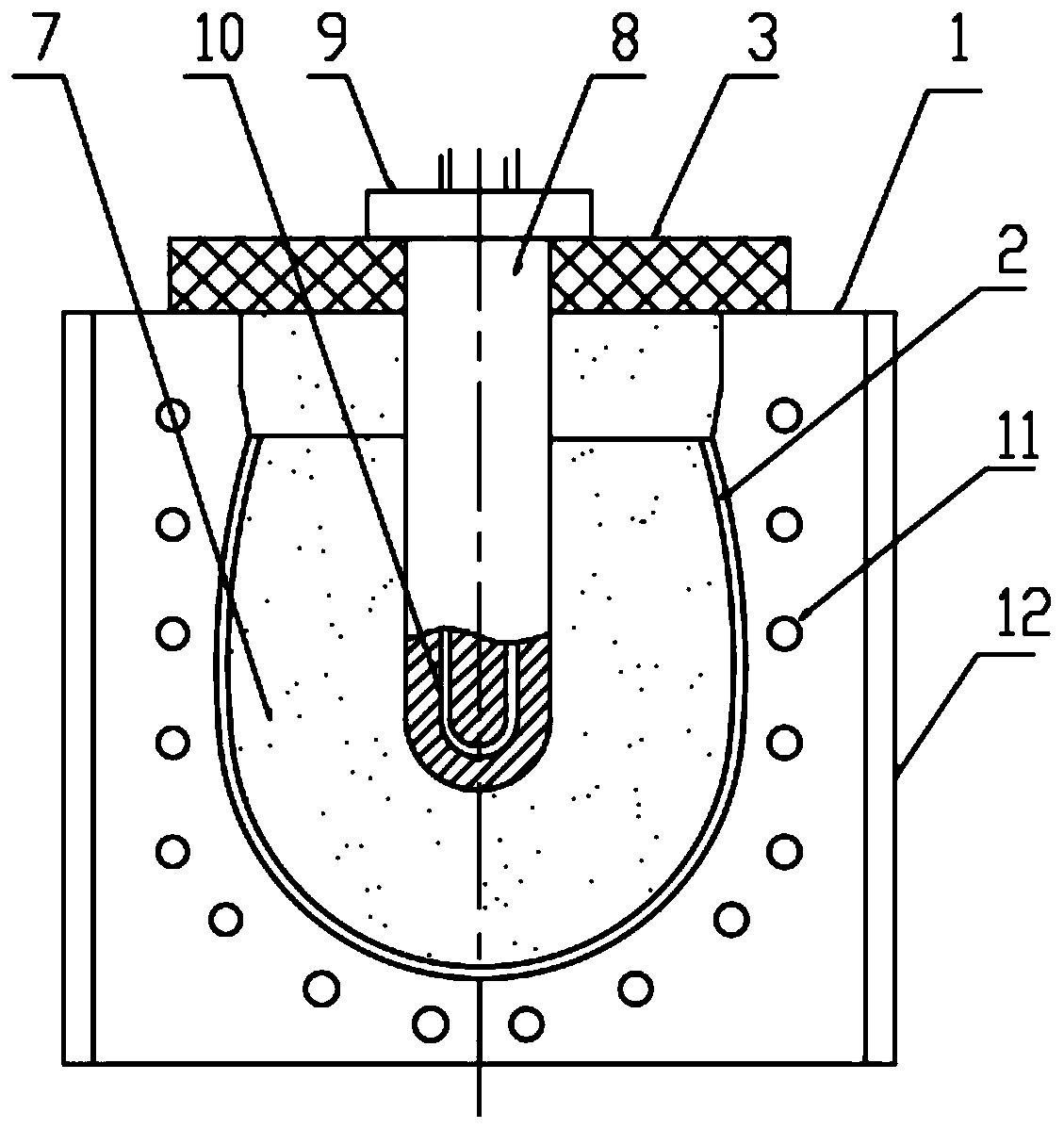

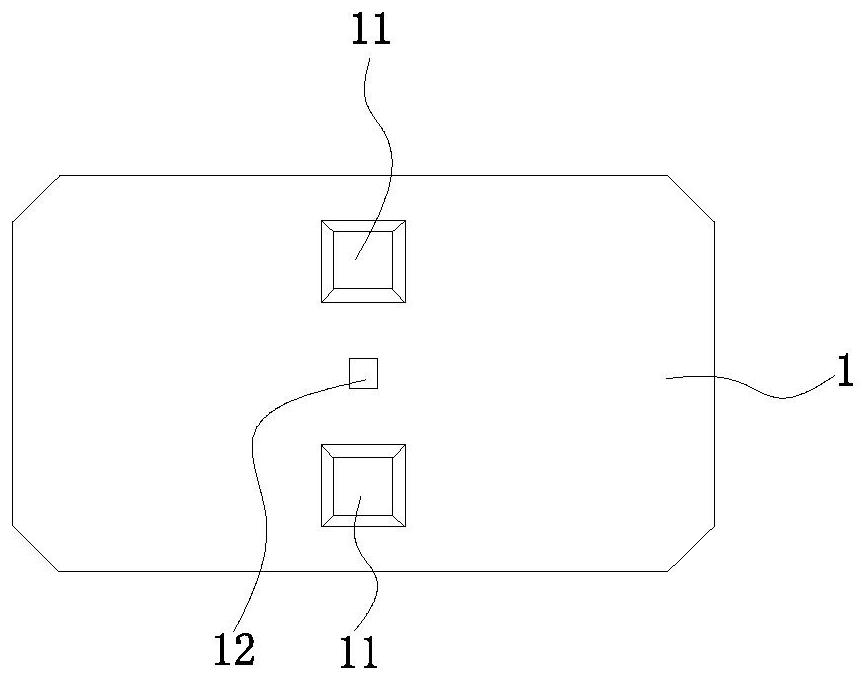

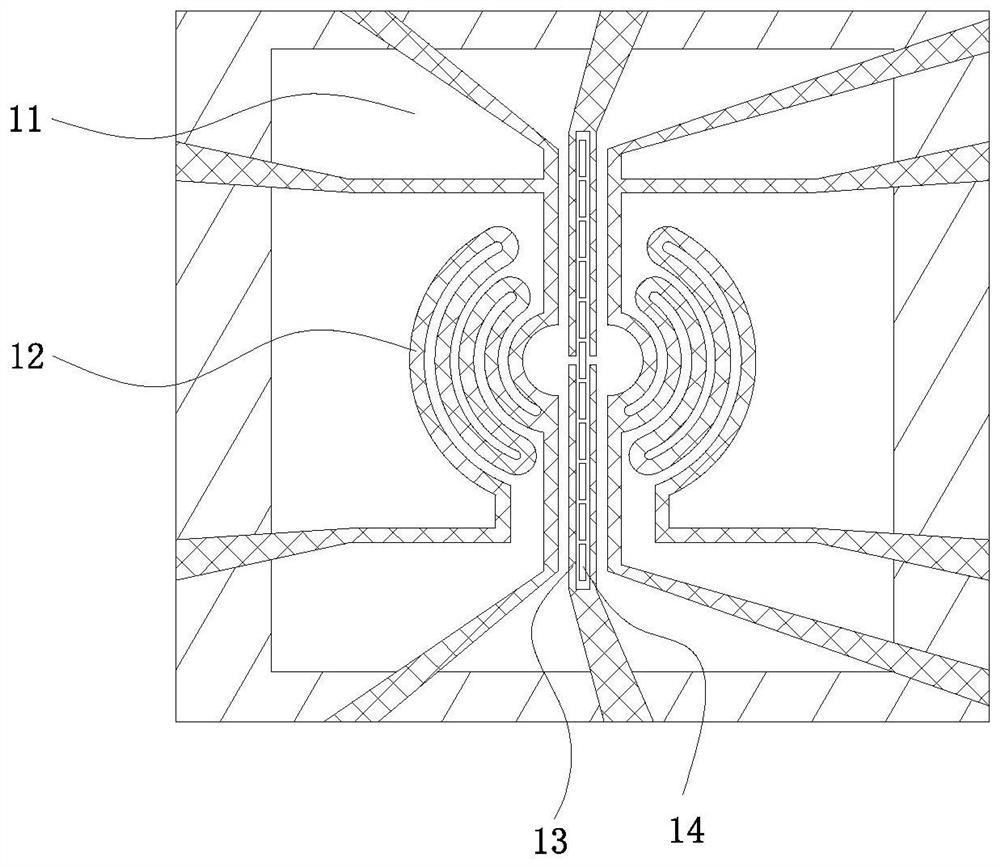

High-resolution in-situ fluid turbulence heating chip of transmission electron microscope

PendingCN111879797AAdd spoilersFlow controllableScanning probe techniquesMaterial analysis by transmitting radiationPhysicsMetallic bonding

The invention relates to a high-resolution in-situ fluid turbulence heating chip of a transmission electron microscope, which is structurally characterized in that an upper sheet and a lower sheet arecombined through a metal bonding layer and are self-sealed to form an ultrathin chamber; the upper piece is provided with two sample injection ports and an upper central window; the lower sheet is provided with a fluid inlet, a fluid outlet, a fluid flow channel, a lower central window, a micro-turbulence column array, a heating layer and an insulating layer; the heating layer is provided with four contact electrodes and a spiral annular heating wire; the lower central window serves as the center and is located in the central area of the spiral annular heating wire; the fluid inlet and the fluid outlet are symmetrically arranged relative to the central window, and the lower central window is located in the center of the heating layer; a micro-turbulence column array is arranged on the lower central window; the chip has the advantages of being rapid in heating and cooling, high in resolution ratio, accurate in temperature control, controllable in fluid flow direction and low in sampledrift rate.

Owner:XIAMEN UNIV

Integrated label printing device

ActiveCN110712426AReduce measurement errorImprove drying efficiencyPrinting press partsWebs handlingEngineeringAir heater

The invention discloses an integrated label printing device. The integrated label printing device comprises a body, wherein a first air heater is mounted at the top end of the outer portion of the body; an unwinding mechanism is mounted on the left side of the body; a winding mechanism is mounted on the right side of the body; a first dryer, a first guiding device, a printing mechanism, a second dryer, a press-fit mechanism, a third dryer and a second guiding device are sequentially mounted at the top end of the inner portion of the body from left to right; a transmission mechanism is arrangedbelow the first dryer, the first guiding device, the printing mechanism, the second dryer, the press-fit mechanism, the third dryer and the second guiding device; a second air heater is mounted belowthe transmission mechanism; the body is mounted at the top of a base; a control panel is mounted on the base; and a supporting rod is mounted at the bottom end of the base. The integrated label printing equipment is good in drying effect, stable in operation and high in work efficiency.

Owner:广东佳雅实业有限公司

Perforating machine for plastic

InactiveCN105459204AImprove stabilityReduce the probability of driftMetal working apparatusEngineeringMechanical engineering

The invention relates to a perforating machine for plastic. The perforating machine comprises a perforating rod, a sliding groove and two clamping plates. The perforating rod is connected into the sliding groove in a sliding mode, a first connecting rod is hinged to the left end of the perforating rod, and a first crank is hinged to the first connecting rod. A first slide rail is arranged at the right side of the perforating rod, the two clamping plates are sequentially connected to the first slide rail in a sliding mode from left to right, a fixing block is arranged at the right end of the first slide rail, and springs are connected between the clamping plate located on the side away from the sliding groove and the fixing block. The two clamping plates abut against each other, and an opening for the perforating rod to pass through is formed in the clamping plate located on the side close to the sliding groove. A second slide rail is arranged above the two clamping plates and connected with a pressing block in a sliding mode, a second connecting rod is hinged to the pressing block, and a second crank is hinged to the second connecting rod. Compared with the prior art, the pressing block and the two clamping plates are matched to enable a wood board to be fixed more stably, and therefore the stability of the wood board is enhanced, and the probability that the pointed end of the perforating rod makes scratches on the surface of the wood board is lowered.

Owner:CHONGQING RUITING PLASTIC

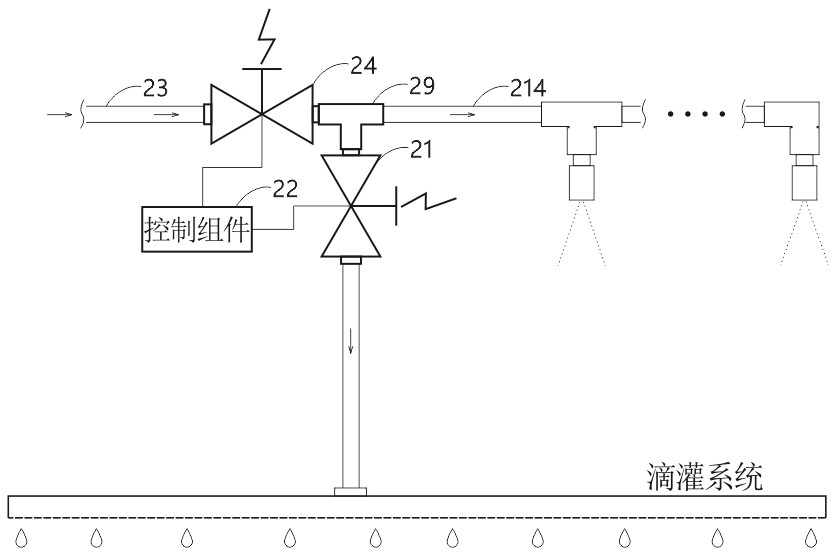

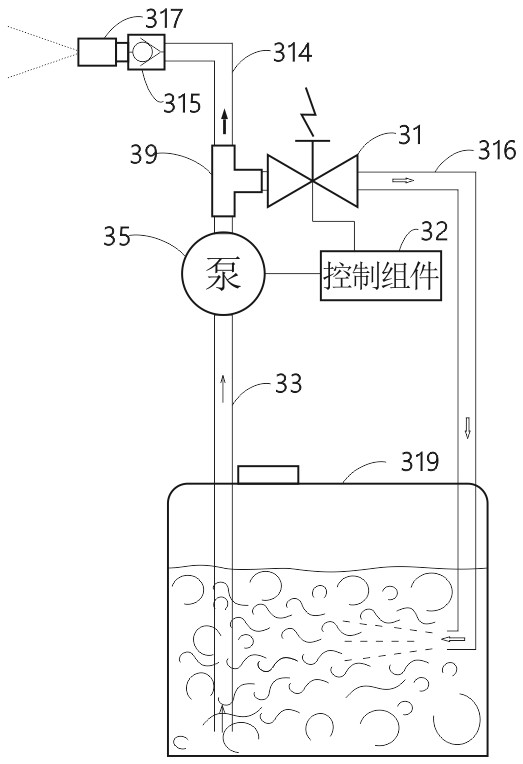

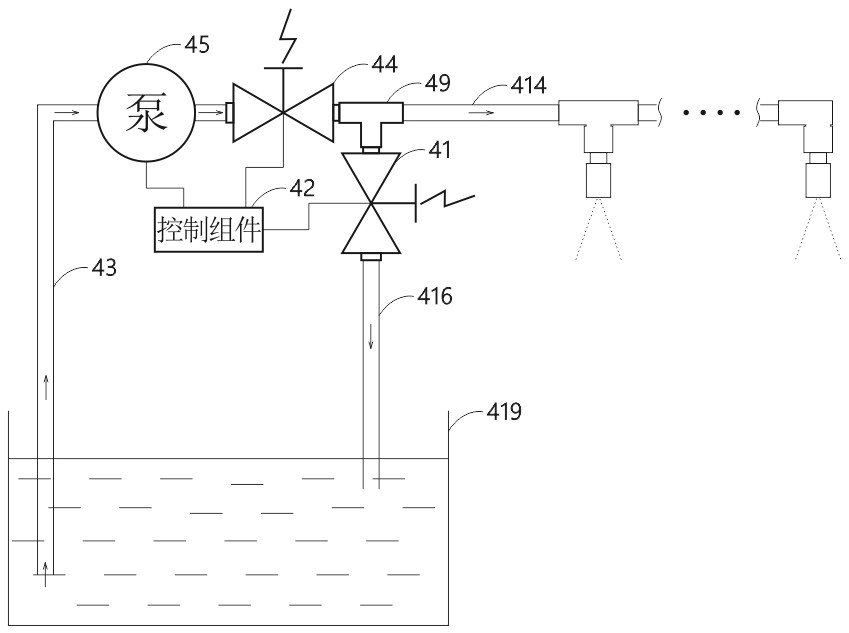

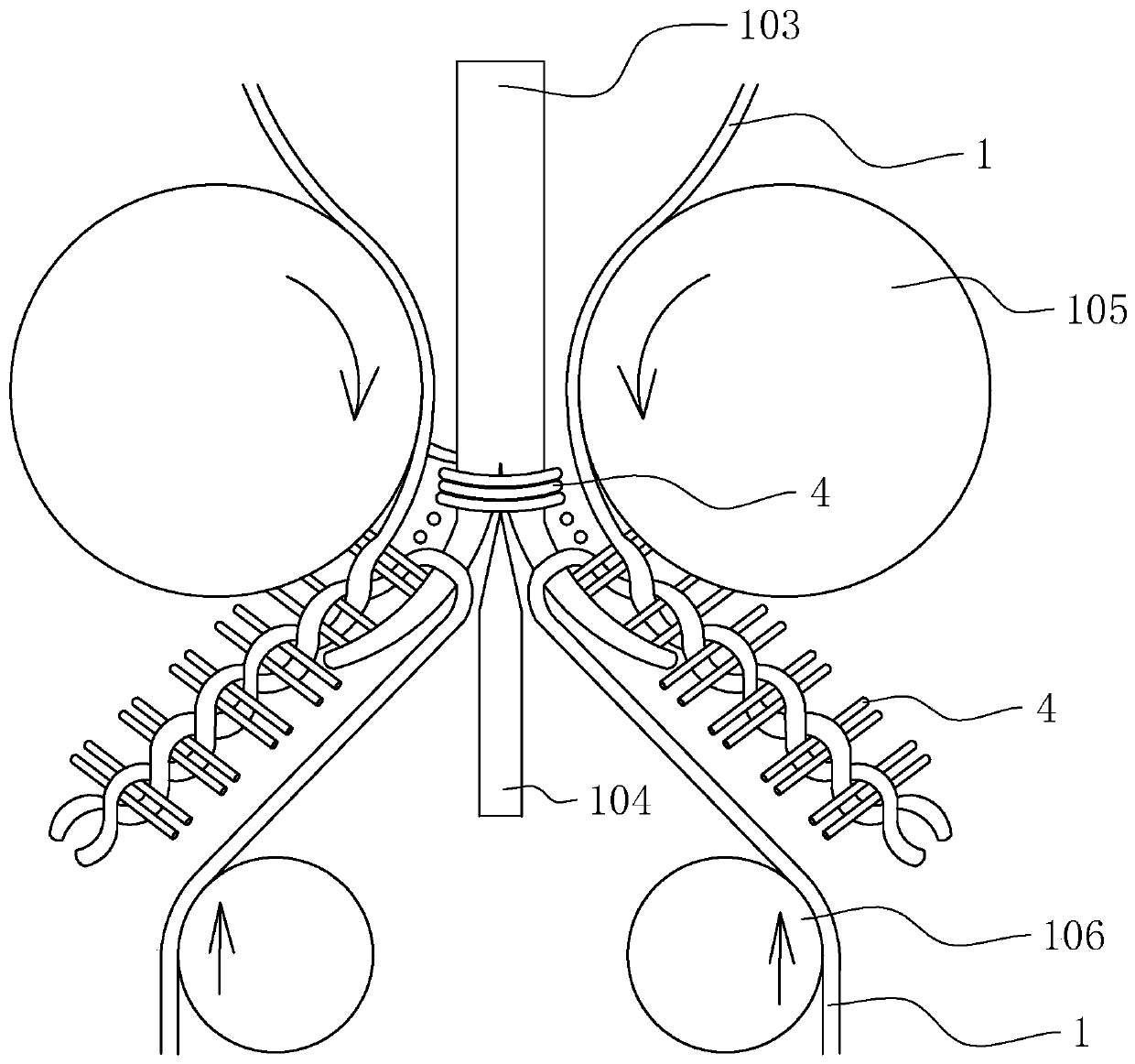

Spraying system, control method and device and spraying equipment

The invention discloses a spraying system, a control method and device and spraying equipment, and belongs to the technical field of spraying. The spraying system comprises a first control valve, a control assembly and a flow dividing pipe, wherein the flow dividing pipe is a three-way pipe; all end ports of the flow dividing pipe are respectively connected with the input end of the first controlvalve, a pressure pipeline and the spraying pipeline; when the first control valve is turned off, liquid conveyed by the pressure pipeline flows to the spraying pipeline through the flow dividing pipe, and a spraying nozzle obtains the liquid by the spraying pipeline to carry out spraying; and when the first control valve is turned on, as the pressure of the output end of the first control valve is very low, the liquid conveyed by the pressure pipeline automatically flows to the output end of the first control valve through the flow dividing pipe, the spraying nozzle stops spraying, and the output end of the first control valve enables the liquid to flow into a liquid storage container through a liquid discharge pipe. The invention can solve the problems that due to injection air flow in the spraying process, problems of increase of the fog drop drifting rate, increase of the off-target rate, liquid dropping and the like are caused, resulting in waste of water or medicine liquid, and the environment pollution is caused by floating and off-target of the medicine liquid.

Owner:HUNAN DIHONG WULIAN TECH CO LTD

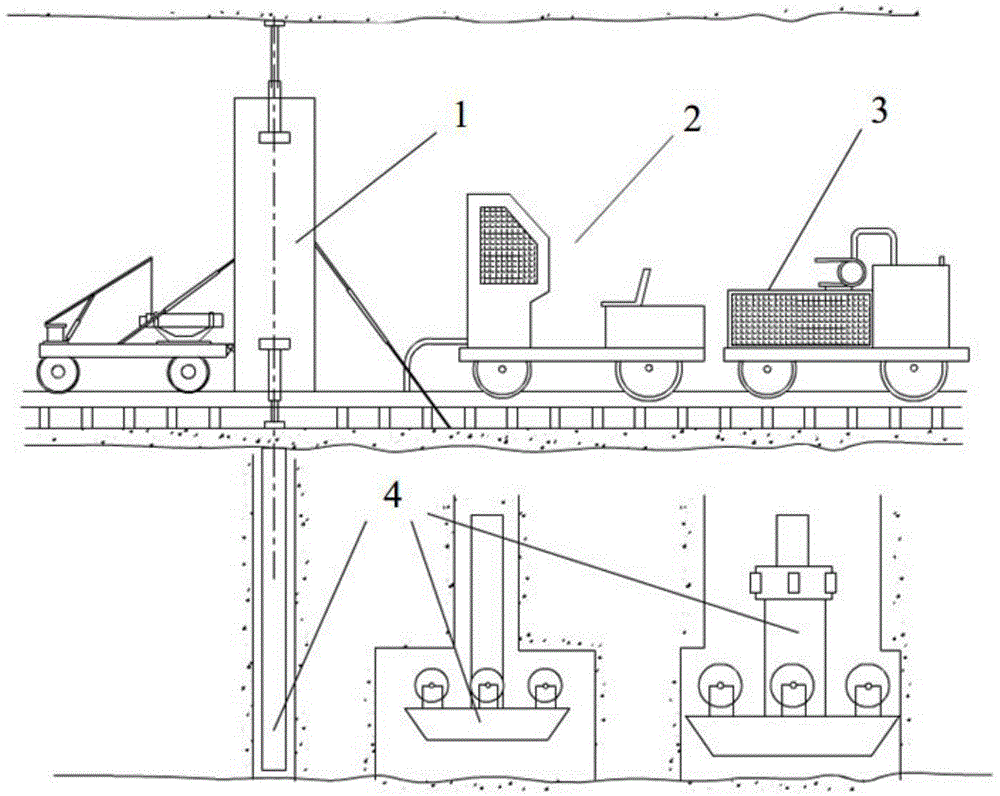

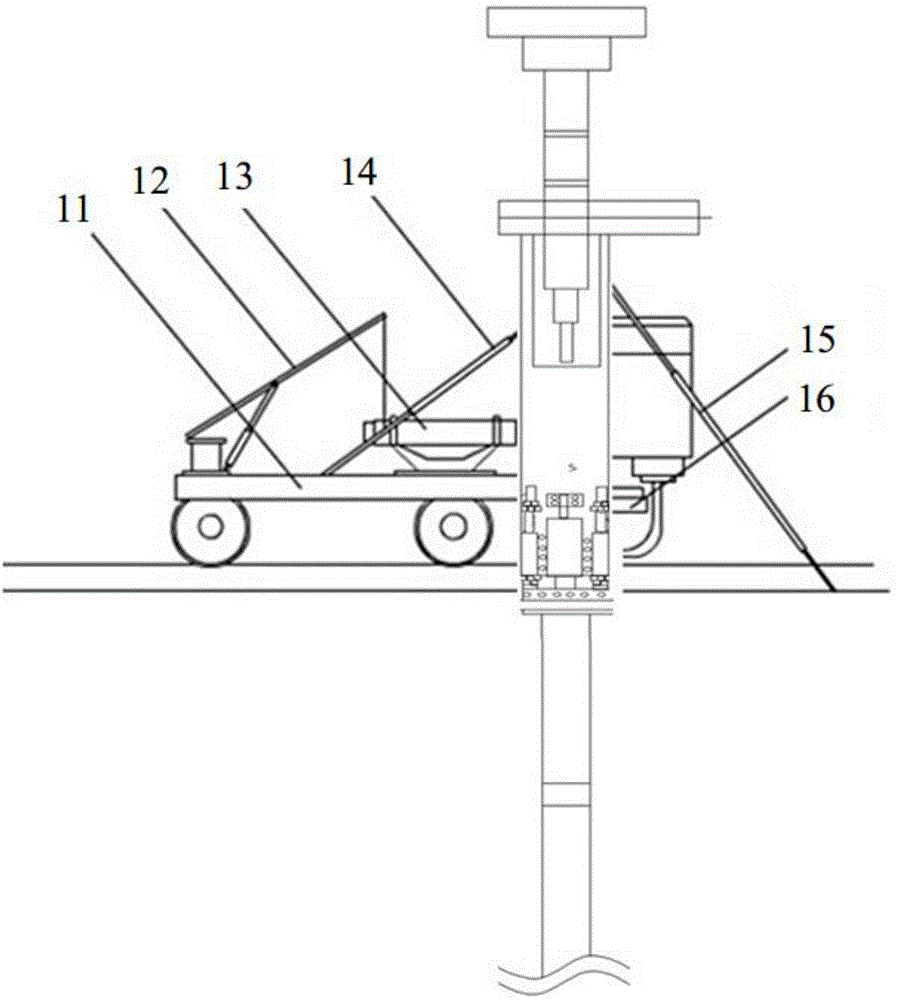

Gadder with safety supporting unit

InactiveCN104929518ASave manpower and material resourcesImprove work efficiencyDerricks/mastsDirectional drillingEngineeringDrill pipe

The invention discloses a gadder with a safety supporting unit, used in raise borers. The gadder comprises the safety supporting unit; the safety supporting unit comprises a drill stand and hydraulic legs; the hydraulic legs comprise upper hydraulic legs and lower hydraulic legs; the upper hydraulic legs used for supporting a tunnel roof are vertically disposed above the drill stand and are horizontally aligned; the lower hydraulic legs used for supporting the drill stand are disposed below the drill stand and are perpendicular to the ground or of a certain angle relative to the ground. The gadder has the advantages that the hydraulic legs are provided, the problems that the existing upper and lower supports are difficult to adjust and prone to loosening, so that offset of drill pipes and the like occur are solved, a lot of manpower and resources are saved, work efficiency is greatly improved, two setting modes of the lower hydraulic legs, namely vertical and tilted modes, are provided to allow flexible adjustment of the drill pipes when the offset occurs, and the drill stand can be more stable and easy to operate during construction.

Owner:内蒙古上海庙矿业有限责任公司

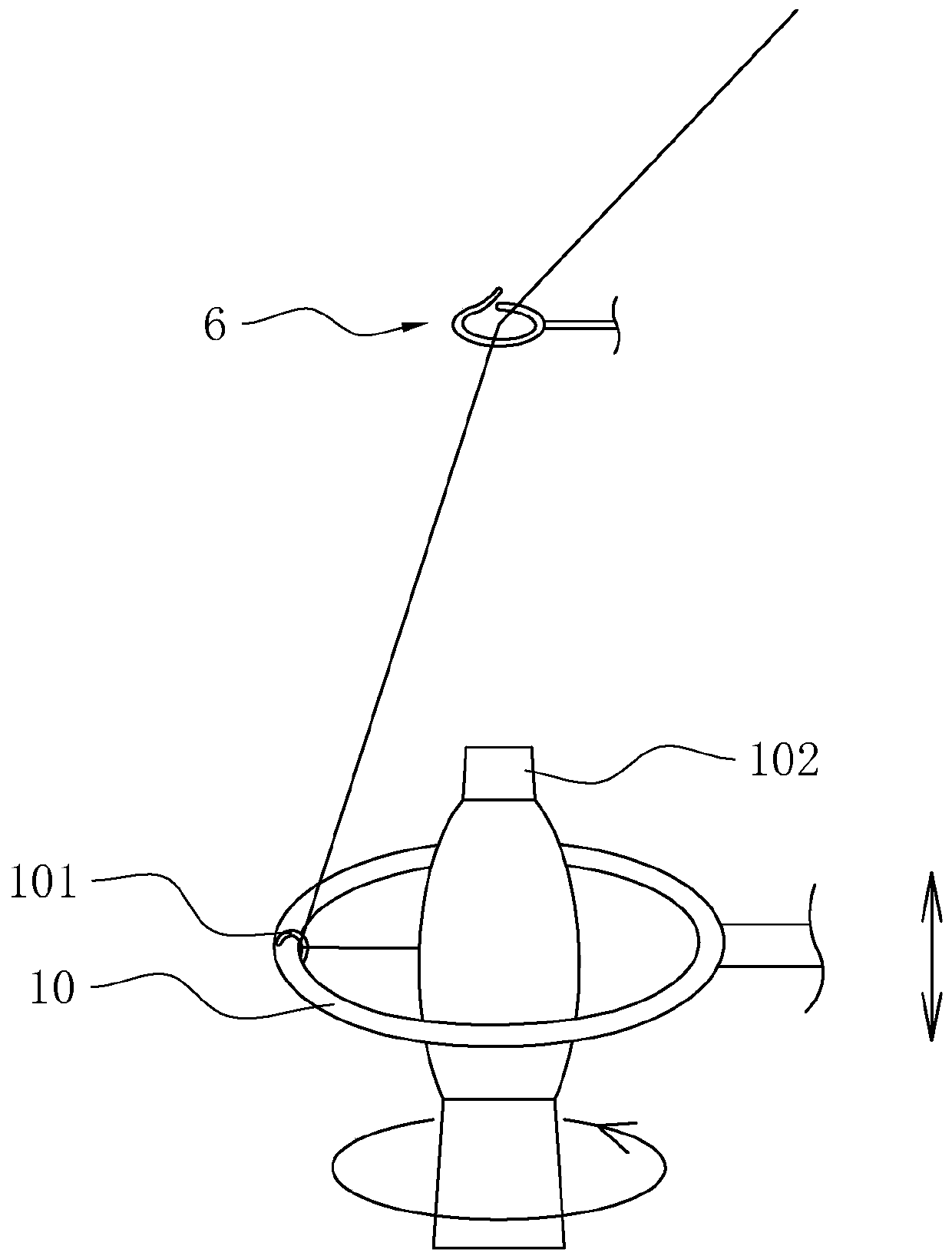

Anti-delinting chenille yarn and production process thereof

The invention relates to an anti-delinting chenille yarn and a production process thereof, and relates to the technical field of chenille weaving. The problem of easiness in delinting of existing chenille yarns is solved. According to the scheme, the chenille yarn comprises two core yarns, hot melt adhesive yarns which are arranged in a hollow mode and fixedly sleeve the peripheries of the core yarns, and wrapping yarns which spirally wrap the outsides the core yarns, and fluff yarns penetrate and are clamped in a among between the core yarns. According to the scheme, the hot melt adhesive yarns are added into the whole chenille yarn, so that the molten glue can bond the core yarns and the fluff yarns in the later spinning process, and the delinting probability is reduced; and moreover, inthe processing technology of the chenille yarn, components such as a ring twisting hook and a steel collar are omitted, the problem of serious power consumption caused by friction between the ring twisting hook and the steel collar can be avoided, and limitation of the steel collar on the winding outer diameter of a finished product is not needed, so that more chenille yarns can be wound at a time, and the processing efficiency is improved. Finally, by the scheme, the chenille yarns with good lint resistance can be produced.

Owner:ZHEJIANG LIDA MODERN TEXTILES

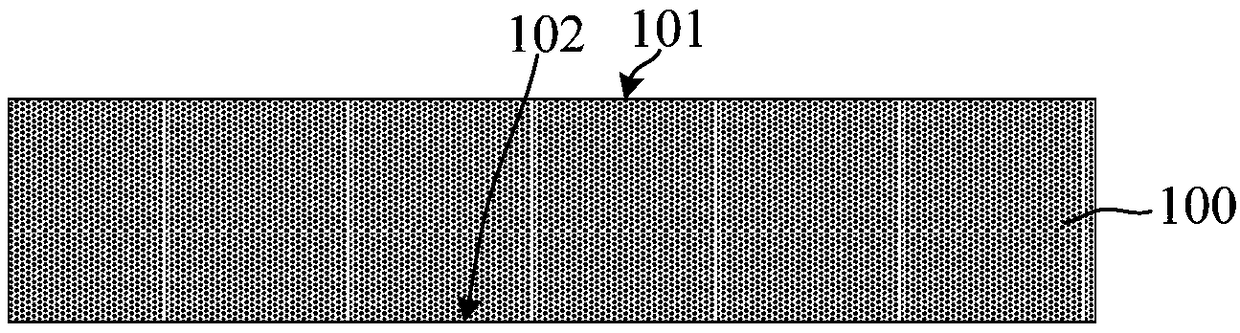

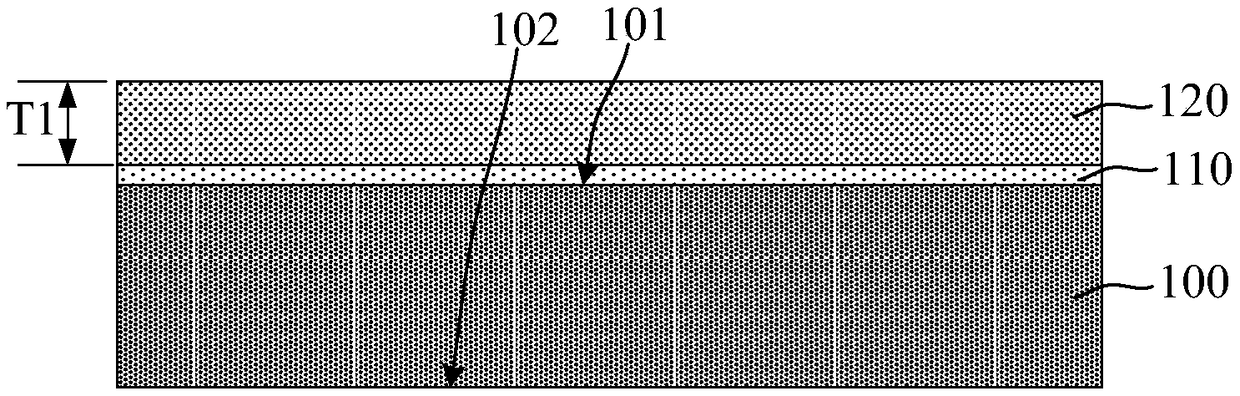

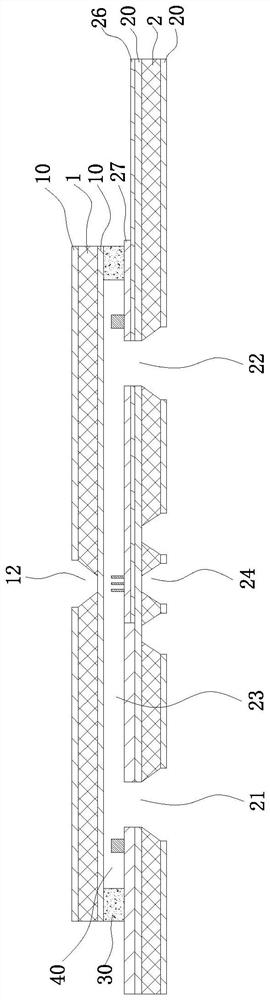

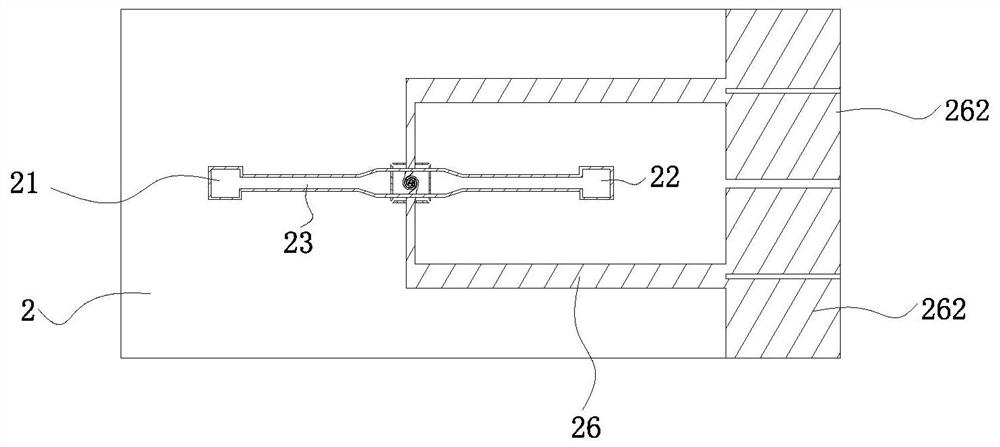

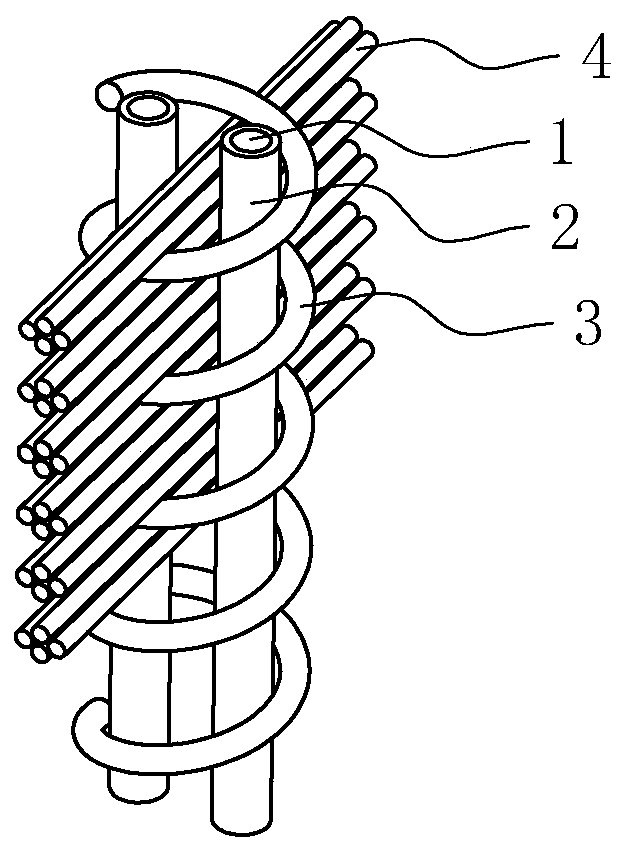

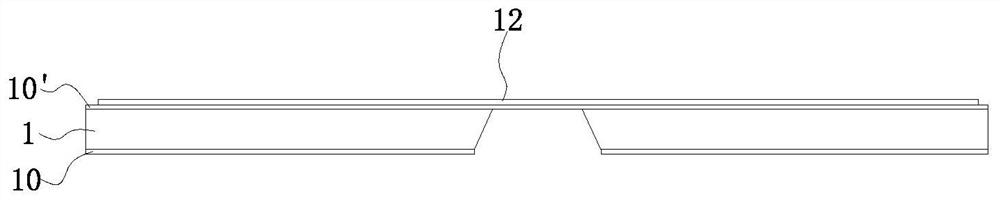

Transmission electron microscope high-resolution in-situ suspension type temperature difference pressurization chip and preparation method thereof

PendingCN112129786AEasy to placeReduce the probability of driftElectric discharge tubesMaterial analysis by transmitting radiationHemt circuitsElectron microscope

The invention relates to a transmission electron microscope high-resolution in-situ suspension type temperature difference pressurization chip and a preparation method thereof. The chip comprises a substrate of which two sides are covered with insulating layers, a central window is arranged in the middle part of the substrate, the central window is suspended, the central window is also covered with a support layer, two heating wires which are symmetrically arranged left and right and two pressurizing circuits which are symmetrically arranged up and down are arranged on the supporting layer inthe central window, the two pressurizing circuits are positioned in a gap between the two heating wires, the heating wires are connected with four heating electrodes, the heating electrodes are connected to different positions of the heating wires through heating lines, the pressurizing circuits are connected with pressurization electrodes, the pressurization electrodes are connected with the corresponding pressurizing circuits through pressurizing lines. The chip can achieve the temperature difference function and the pressurization function at the same time.

Owner:XIAMEN UNIV

Matching assembly for research and development of copper strip crystallizer and application thereof

The invention provides a matching assembly for research and development of a copper strip crystallizer and application thereof, and belongs to the technical field of matching assemblies for research and development of crystallizers and application thereof. The matching assembly comprises adjusting detection rods, adjusting pieces and switching mechanisms, wherein an adjusting limiting assembly isarranged between the adjusting detection rods, a precision positioning mechanism is movably connected to the adjusting detection rods, and a switching driving mechanism is arranged between the switching mechanisms. According to the matching assembly for research and development of the copper strip crystallizer and the application thereof, detection switching pieces are used for driving the switching mechanisms, the switching mechanisms drive the adjusting pieces through the switching driving mechanism, and meanwhile in combination with the precision positioning mechanism, the situation that anarrow edge straightening device falls off due to deviation and collision of a dummy bar is solved from the source; and the working efficiency of the crystallizer is improved, a large number of powerresources are saved, the workload of workers is reduced, meanwhile, the bulging condition of a plate blank and the probability of copper leakage accidents are reduced, and the safety of the copper strip crystallization process and the quality after crystallization are greatly improved.

Owner:JIANGXI KAIAN INTELLIGENT LTD BY SHARE CO LTD

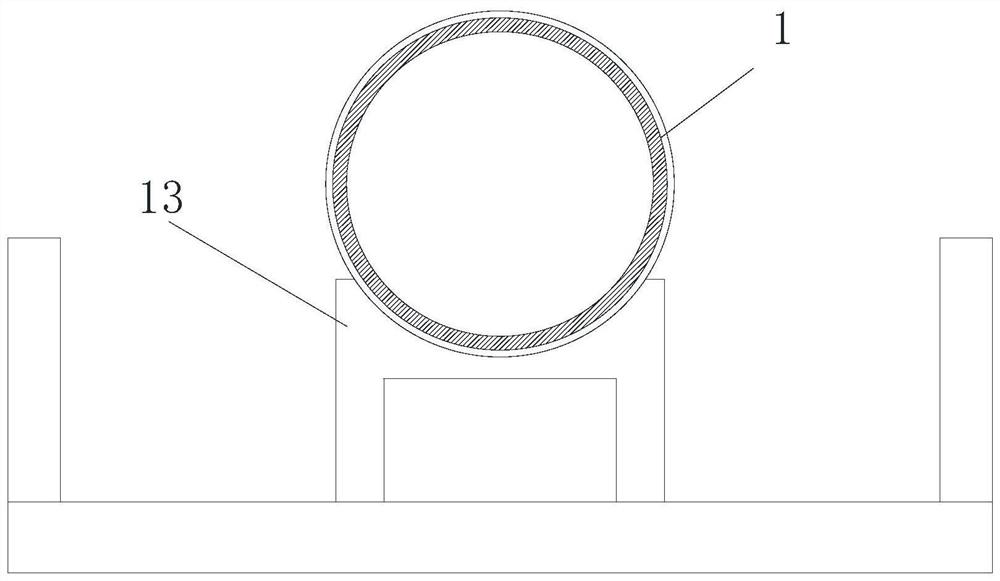

Timber saw blade cutting machine

InactiveCN104972518AReduce the probability of driftReduce waste of resourcesCircular sawsEngineeringMechanical engineering

The invention discloses a timber saw blade cutting machine comprising a pedestal and an operation table arranged on the pedestal; the operation table is provided with a saw blade fixed on a bearing rack; a bearing rack bottom piece is placed in a pedestal slide slot and moves in the slide slot; the slide slot and the saw blade are in a same direction. One side of the operation table is vertically provided with a fixed stop plate having same direction with the saw blade. The bearing rack bottom piece can slide in the pedestal slide slot so as to drive the saw blade to move in a horizontal direction, thus adjusting horizontal distances between timbers, two pressure rollers and the saw blade, so the two pressure rollers can be in best force application positions above the timber; the timber saw blade cutting machine is best in effect, most convenient in operation, thus reducing timber offset probability, and reducing timber resource waste.

Owner:JIANGSU DONGJIA WOOD IND

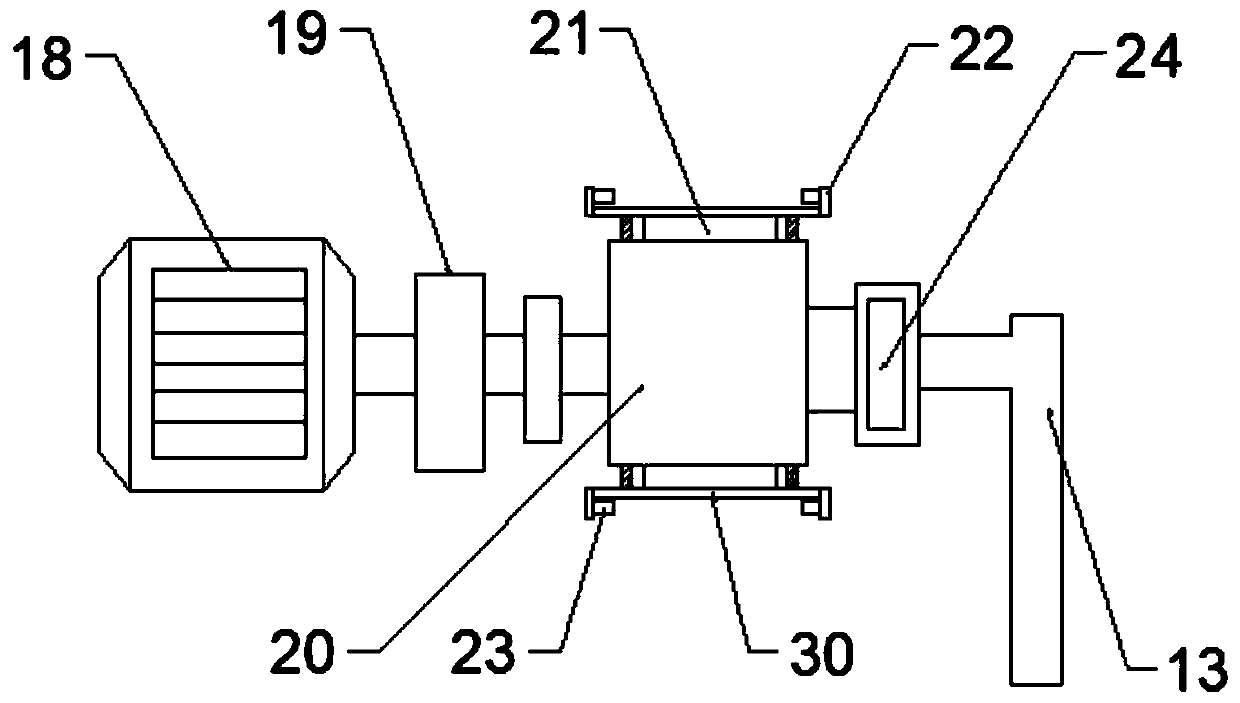

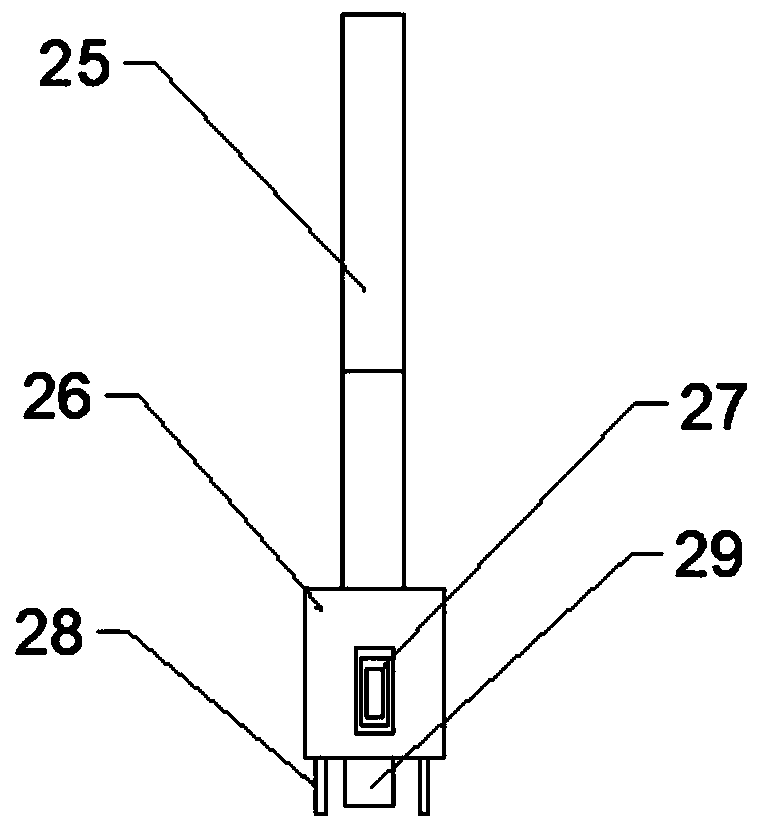

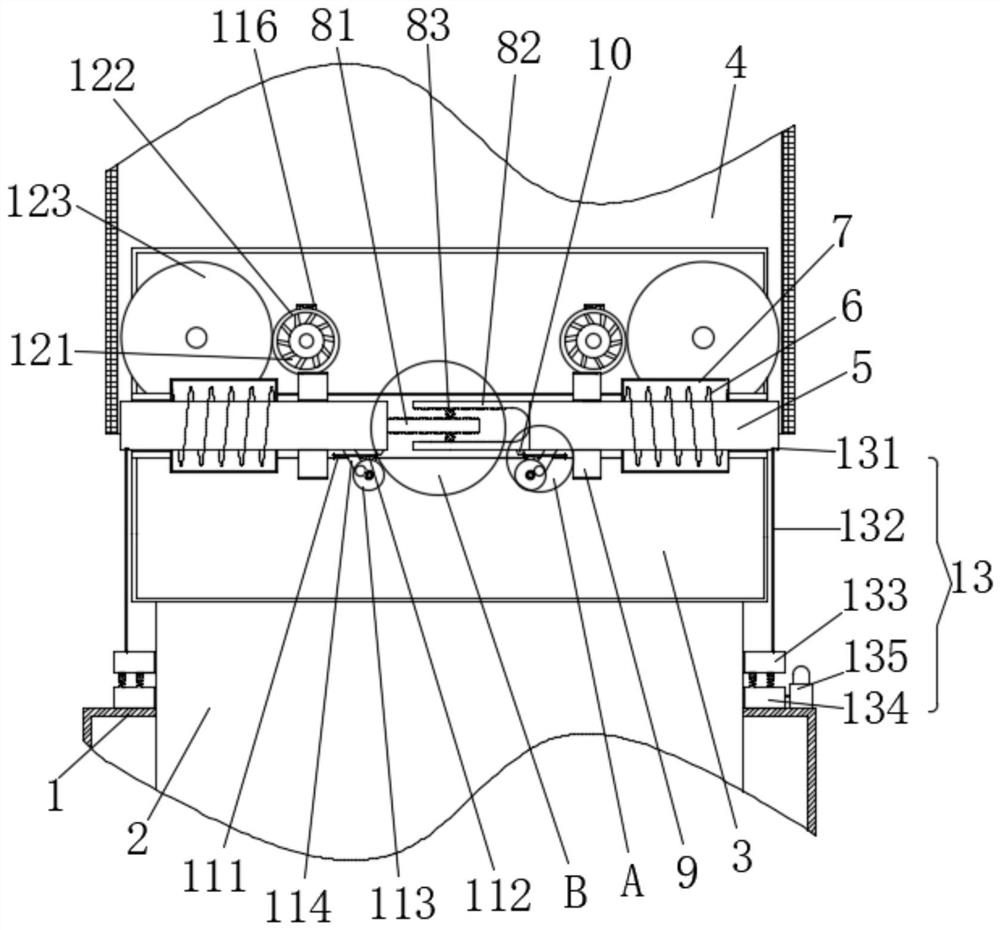

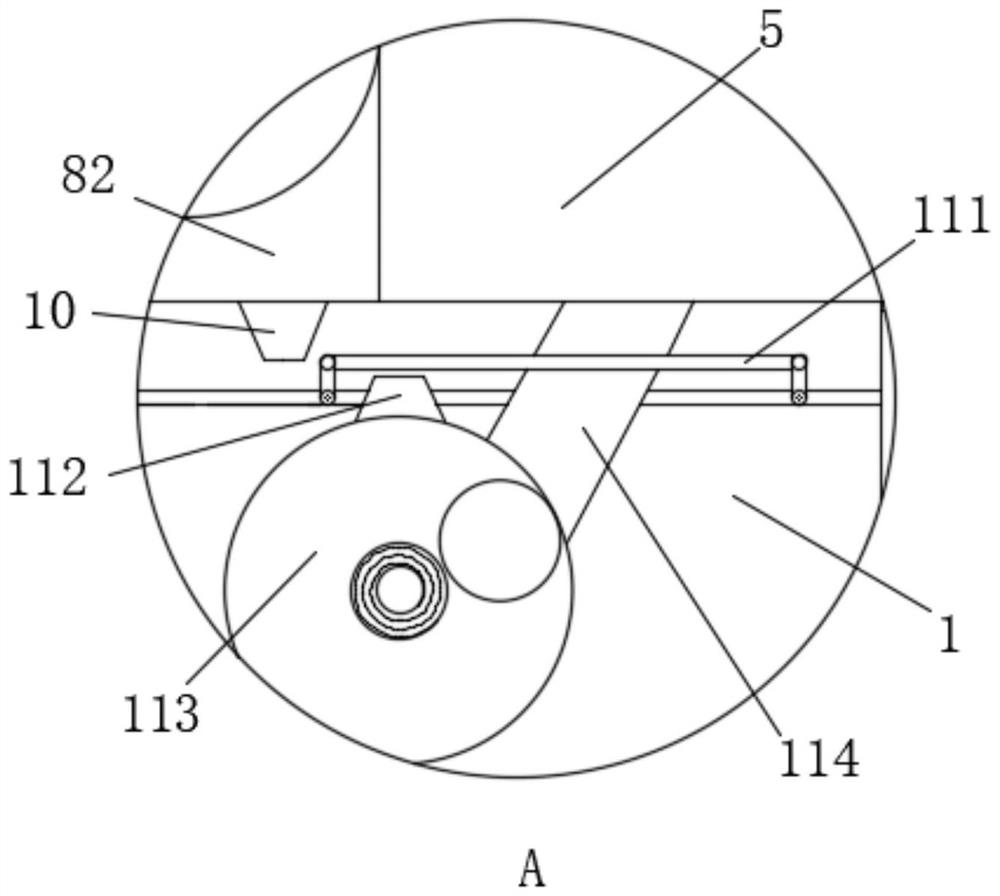

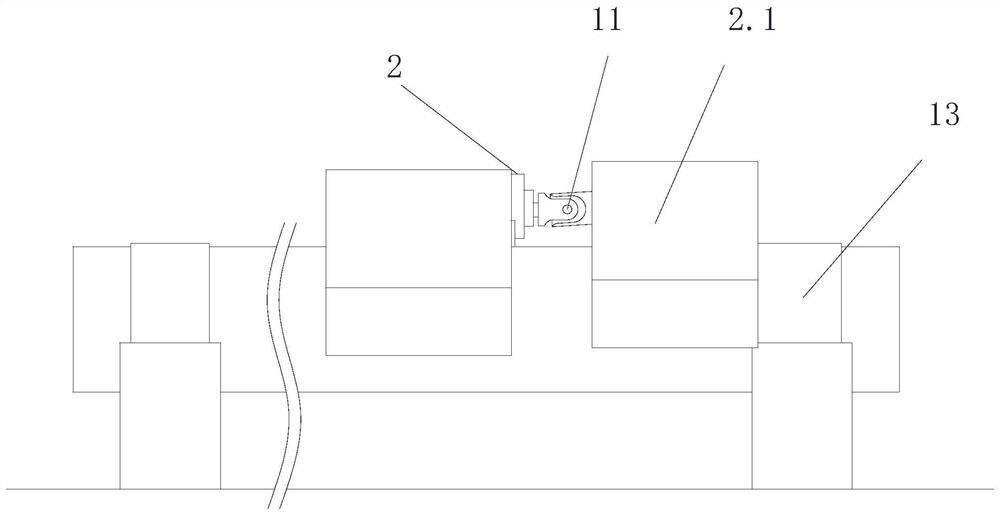

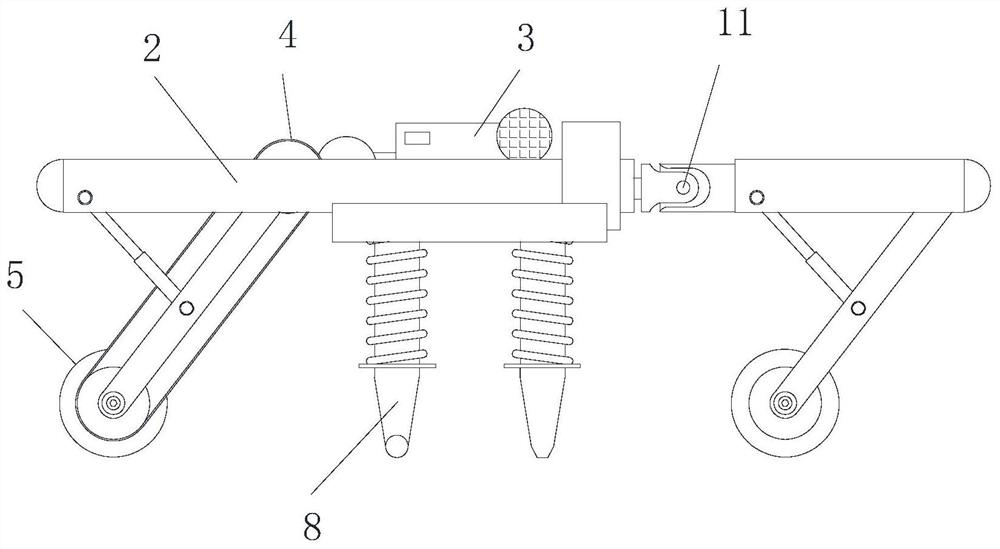

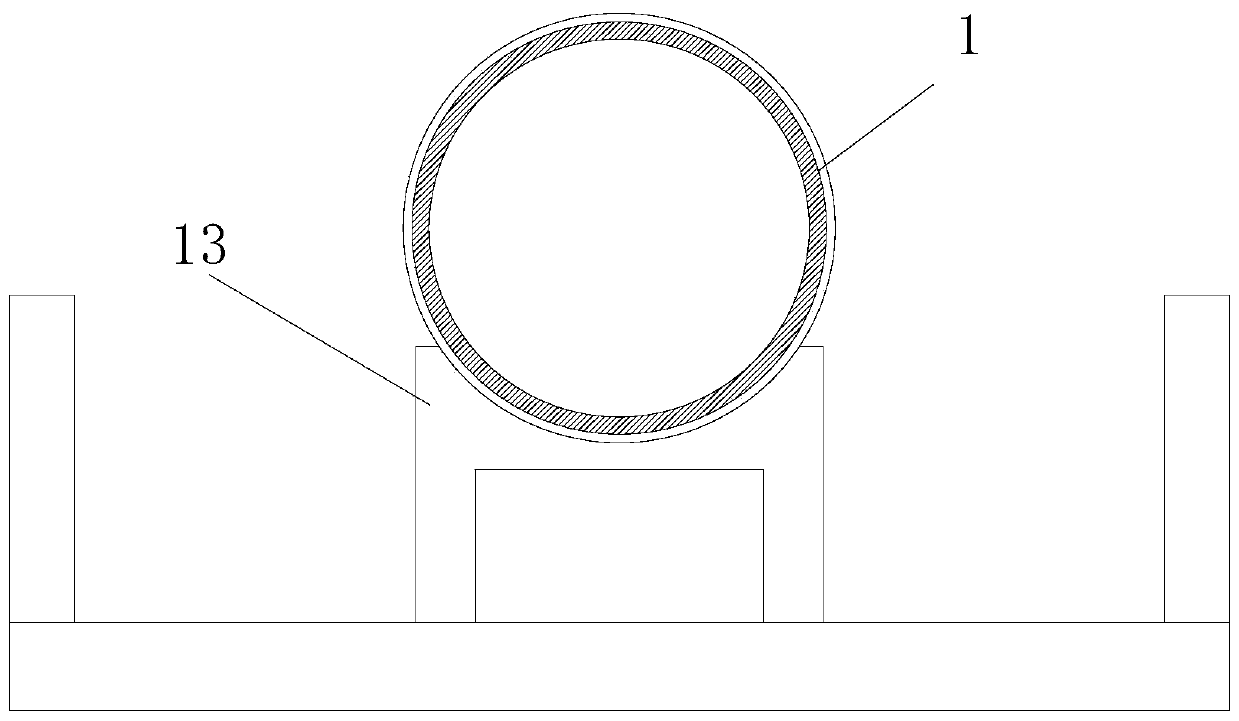

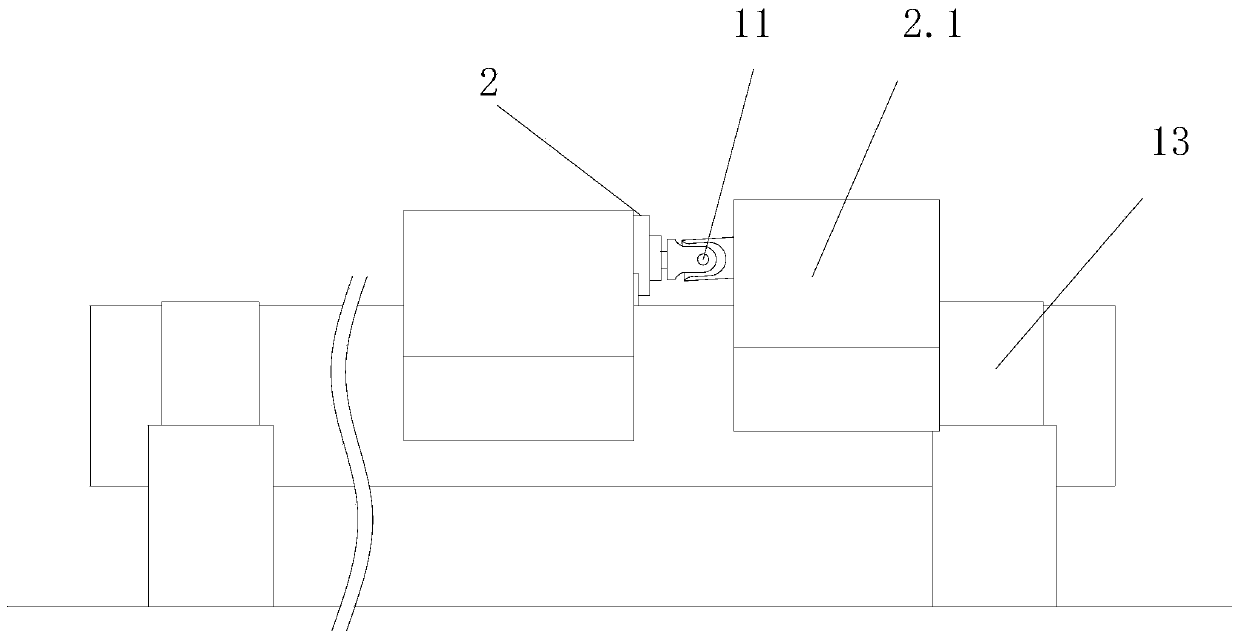

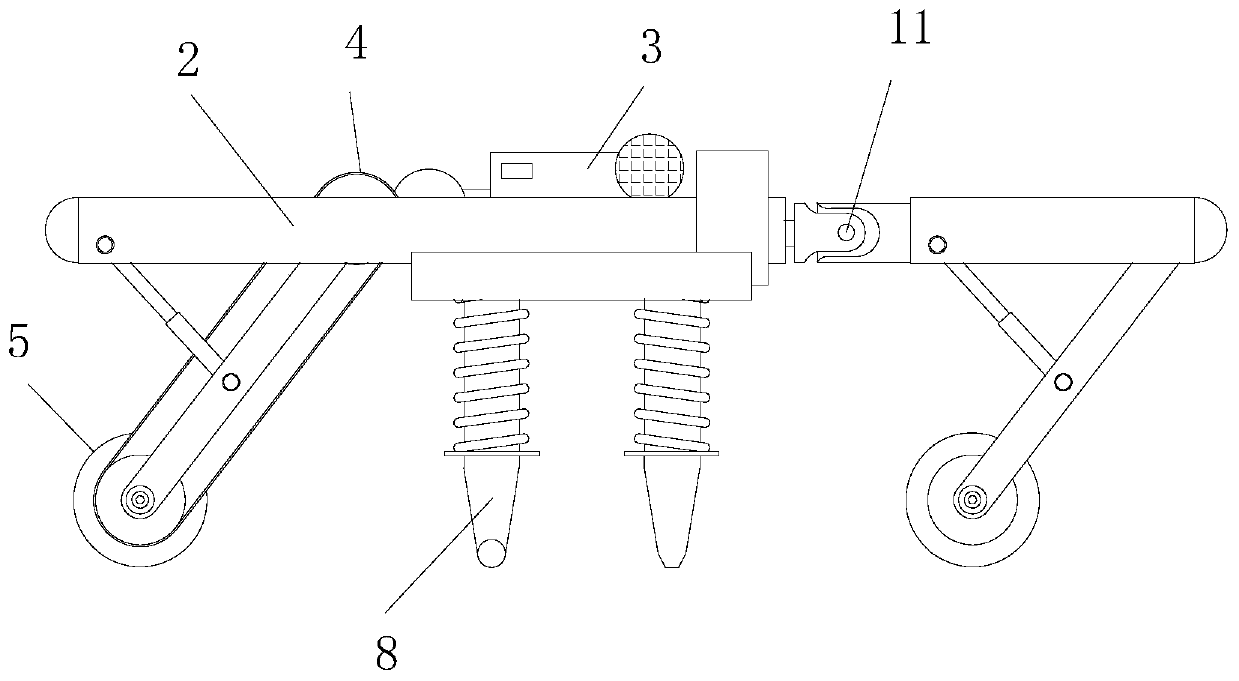

Monitoring and early warning device for high-consequence areas of oil and gas pipelines

ActiveCN111174109BStable arrangementReduce the probability of driftPipeline systemsStructural engineeringMoving parts

The invention discloses a monitoring and early warning device for high-consequence areas of oil and gas pipelines. Mechanism, stability auxiliary mechanism and monitoring mechanism, the movement mechanism includes a driving unit and a moving part, and the driving unit drives the moving part to move on the outer wall of the oil and gas pipeline through the transmission mechanism; the stabilizing mechanism includes at least two counterweights, and the two arms of the main frame are respectively set There is a configuration so that the center of gravity of the main frame falls to the center line; the stability assisting mechanism includes a friction fit piece, which is used to provide circumferential friction with the outer wall; the monitoring mechanism is used to monitor the oil and gas pipeline. In the monitoring and early warning device for high-consequence areas of oil and gas pipelines provided by the present invention, the main frame can be stably arranged on the oil and gas pipeline, and at the same time, the friction force is increased through the stability auxiliary mechanism to reduce the probability of main frame deviation, and the support device can be passed.

Owner:CHINA ACAD OF SAFETY SCI & TECH

Monitoring and early warning device for high consequence area of oil and gas pipeline

ActiveCN111174109AStable arrangementReduce the probability of driftPipeline systemsGravity centerMoving parts

The invention discloses a monitoring and early warning device for a high consequence area of an oil and gas pipeline. The device comprises an inverted-U-shaped or inverted-V-shaped main frame buckledon the outer wall of the upper half portion of the oil and gas pipeline; a moving mechanism, a stabilizing mechanism, a stabilizing auxiliary mechanism and a monitoring mechanism are arranged on the main frame, the moving mechanism comprises a driving unit and a moving part, and the driving unit drives the moving part to move on the outer wall of the oil-gas pipeline through a transmission mechanism; the stabilizing mechanism comprises at least two counterbalance weights, and two arms of the main frame are each provided with one counterbalance weight so that the gravity center of the main frame can fall on the center line; the stabilizing auxiliary mechanism comprises a friction attaching piece, and the friction attaching piece is used for providing circumferential friction with the outerwall; and the monitoring mechanism is used for monitoring the oil-gas pipeline. According to the monitoring and early warning device for the high-consequence area of the oil and gas pipeline, the mainframe can be stably arranged on the oil and gas pipeline, meanwhile, the friction force is increased through the stabilizing auxiliary mechanism, the deviation probability of the main frame is reduced, and a supporting device can be passed.

Owner:CHINA ACAD OF SAFETY SCI & TECH

Anti-pinch mechanism of sewing machine for footwear processing

InactiveCN113046943AEnsure stability and continuityEnsure safetyLeather sewingWork-feeding meansEngineeringSewing machine

The invention relates to the technical field of footwear processing equipment, in particular to an anti-pinch mechanism of a sewing machine for footwear processing. The anti-pinch mechanism comprises a sewing machine, the sewing machine comprises an operating floor, a sewing machine body is fixedly mounted in the middle of the top of the operating floor, a sewing machine head is fixedly mounted at the right end of the sewing machine body, a sewing machine needle is arranged in the middle of the bottom of the sewing machine head, a nail seat is arranged under the sewing machine needle and fixedly welded to the top of the operating floor, and a conveying mechanism is mounted at the top of the operating floor. According to the anti-pinch mechanism of the sewing machine for footwear processing, two sets of first shaft rods are driven to synchronously and relatively rotate through rotation of a spline rod, so that two corresponding sets of conveying wheels synchronously and relatively rotate to extrude and convey shoes, workers do not need to manually convey the shoes, and the safety of the device during working is effectively guaranteed; and two conveying mechanisms are symmetrically mounted on the front side and the rear side of the nail seat in the front-back direction, and the stability and continuity in the shoe conveying process are effectively guaranteed.

Owner:WENZHOU POLYTECHNIC

Method for fixing mineral leaching rod-shaped bacteria for AFM analysis under strong acid condition

InactiveCN101718802BReduce the probability of driftEasy to fixPreparing sample for investigationMicroorganism based processesCelluloseFiltration

The invention discloses a method for fixing mineral leaching rod-shaped bacteria for AFM analysis under a strong acid condition. In the method, a filter membrane (mixed cellulose ester millpore filter membrane) with an aperture of 0.22 micron is used as a fixing material, a domestic filter (the diameter is 25 millimeters) is used as a filter device, and a disposable medicine injection is utilized for filtration through pressurization. In a preparation process of fixing the mineral leaching bacteria, the filter condition and the filter device have small influences on the activity of the bacteria, no toxicity and convenient operation. In a solution with a pH value of 2, the prepared bacteria have low drift rate, good fixing effect and higher stability, thus an atomic force microscope (AFM) is suitable for analyzing the mineral leaching bacteria under the strong acid condition. The method can be widely applied to the field of AFM researches and has good application prospect and practical values.

Owner:CENT SOUTH UNIV

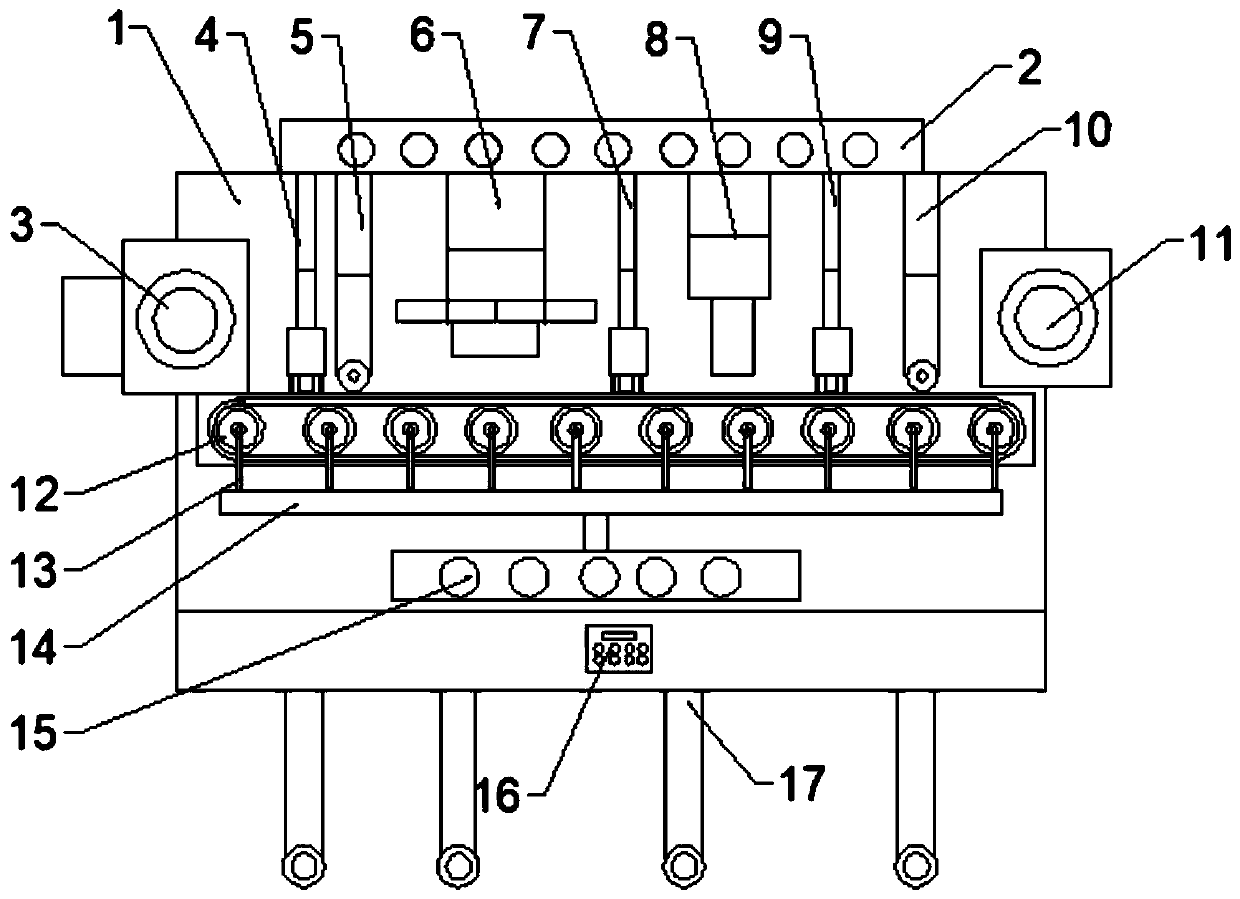

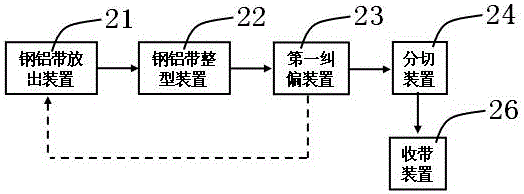

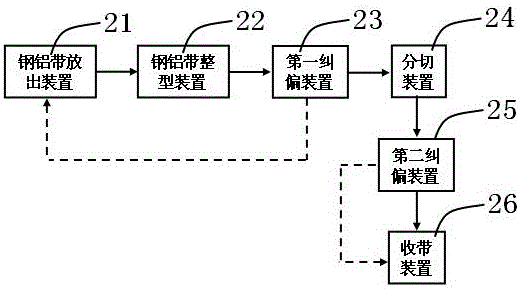

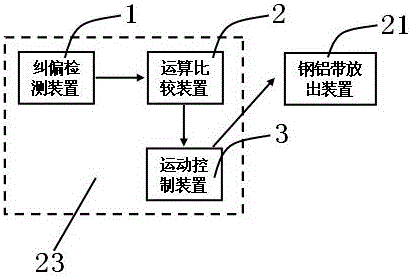

Steel aluminum tape slitting system provided with correction devices

ActiveCN106695336AReduce the probability of driftFor precise cuttingOther manufacturing equipments/toolsMetallurgy

The invention belongs to the technical field of equipment, and particularly relates to a steel aluminum tape slitting system provided with correction devices. The steel aluminum tape slitting system comprises a steel aluminum tape discharging device (21), a steel aluminum tape shaping device (22), a slitting device (24) and a tape winding device (26). The steel aluminum tape slitting system is characterized in that the steel aluminum tape slitting system is further provided with a first correction device (23) that is located between the steel aluminum tape shaping device (22) and the slitting device (24), the steel aluminum tape discharging device (21) discharges a finished steel aluminum tape and conveys the finished steel aluminum tape to the steel aluminum tape shaping device (22), the steel aluminum tape shaping device (22) conveys the discharged steel aluminum tape through rollers and the leveling of the surface is realized, and the steel aluminum tape is sent into the first correction device (23), wherein when the first correction device (23) detects out deviation of the steel aluminum tape, the first correction device (23) sends an instruction to allow the steel aluminum tape discharging device (21) to make path adjustment. The steel aluminum tape slitting system has the following main beneficial technical effects: steel aluminum tape slitting is more precise, the waste of the steel aluminum tape is less, and the cost is lower.

Owner:佛山市顺德区纬博特电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com