Packaging method

A packaging method and packaging layer technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of packaging structure yield and reliability to be improved, so as to shorten the processing cycle, improve yield and reliability , Reduce the effect of lateral impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

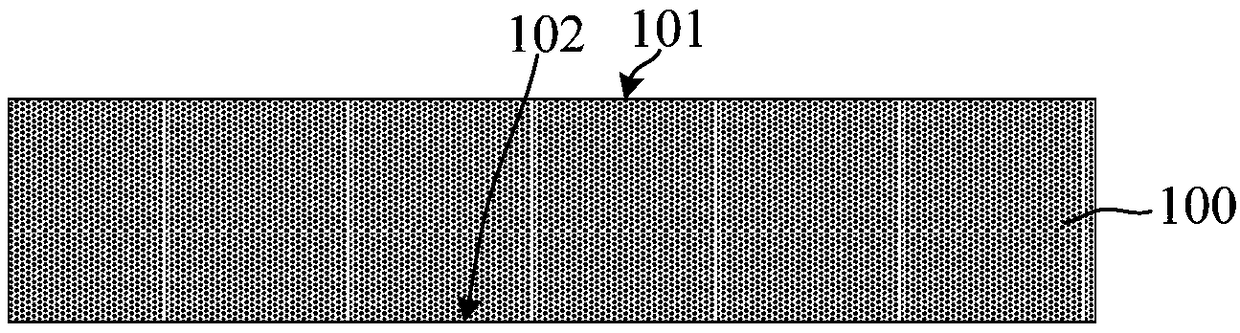

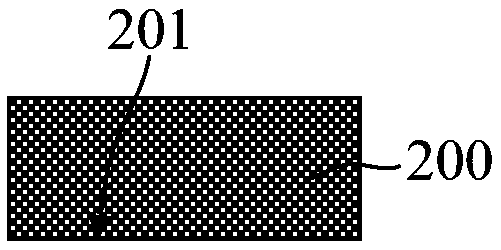

Image

Examples

Embodiment Construction

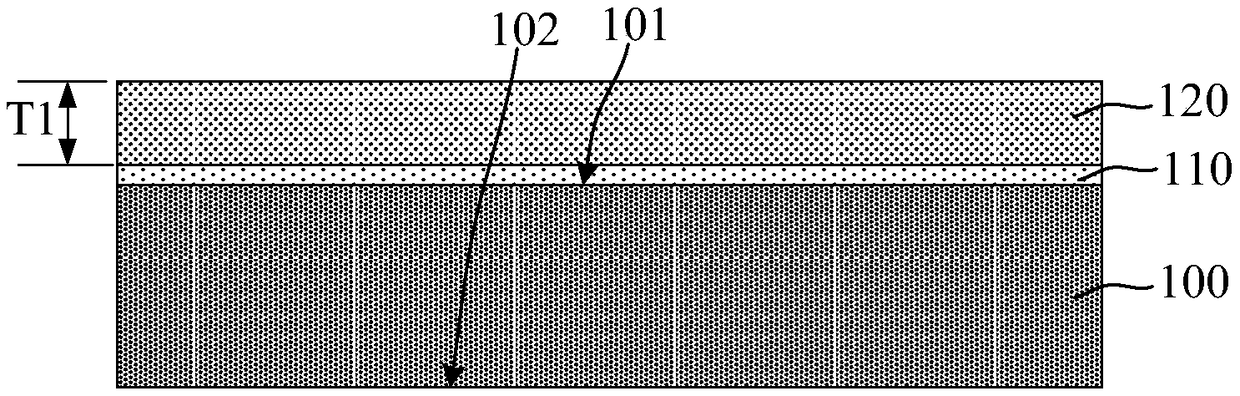

[0025] It can be seen from the background art that the yield and reliability of the packaging structure formed by the current packaging method still need to be improved. The reasons for analyzing the yield and reliability of the packaging structure to be improved are:

[0026] In the current packaging process, compared with the bonding process, the bonding process has better adhesion and chemical stability, so the bonding process has gradually become the main means to achieve wafer-level system packaging and panel-level system packaging.

[0027] However, wafer-level system package or panel-level system package is to bond chips one by one to wafers or other substrates. Due to the large number of chips, in order to shorten the processing cycle of the packaging process, the bonding time is required to be short , and the shorter bonding time will reduce the bonding strength between the chip and the wafer or other substrates; when the encapsulation layer is formed by the subsequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com