Autorotation equipment for motorcycle hub coating

A motorcycle and wheel hub technology is applied in the field of rotation equipment for motorcycle wheel hub coating, which can solve the problems of high workpiece coating defect rate, different rotation speeds, unstable workpiece rotation, etc., so as to improve the processing yield and increase Stability, the effect of protecting the internal structure of the rack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

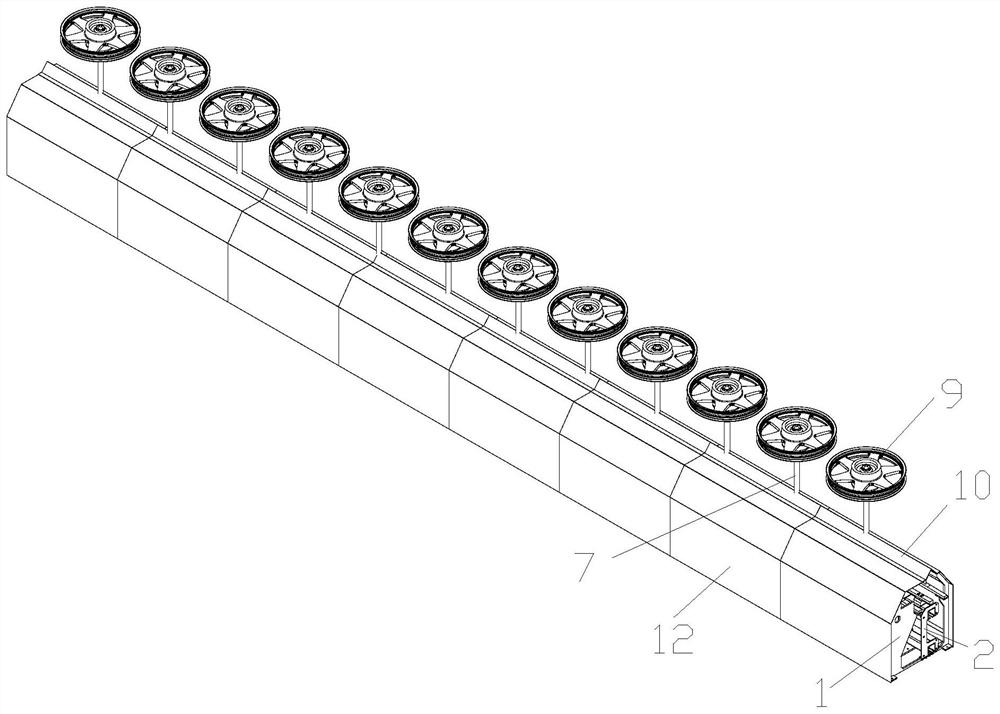

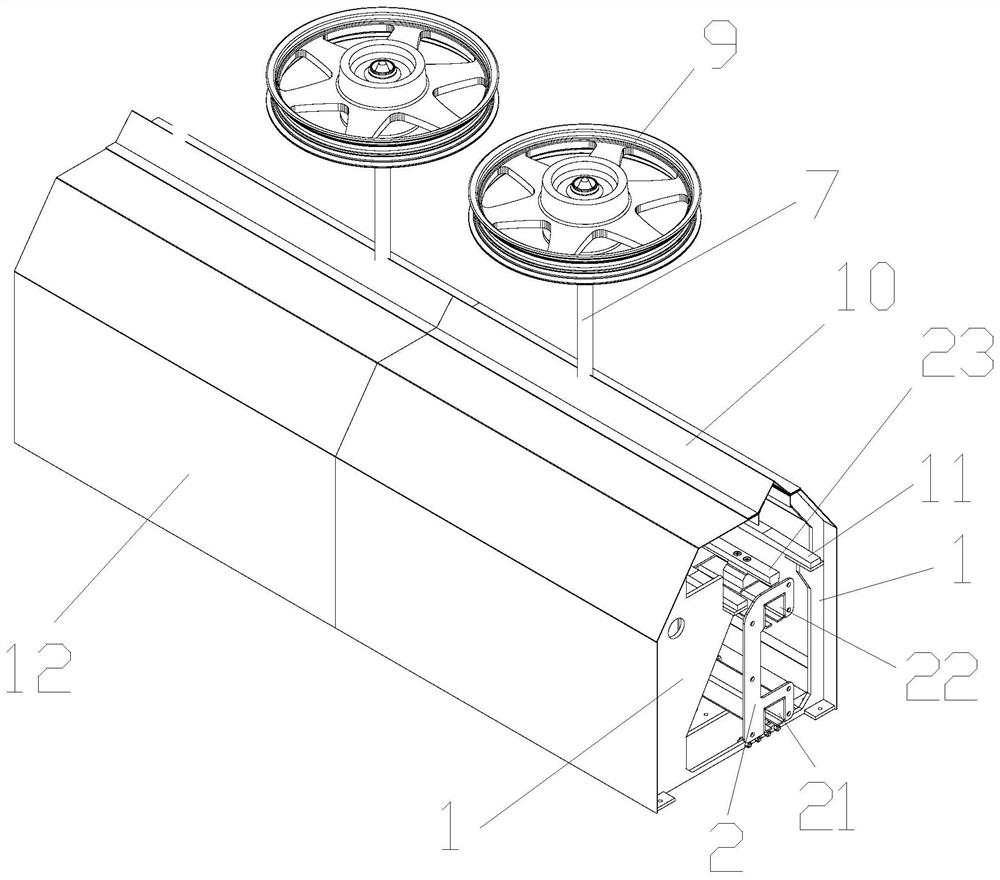

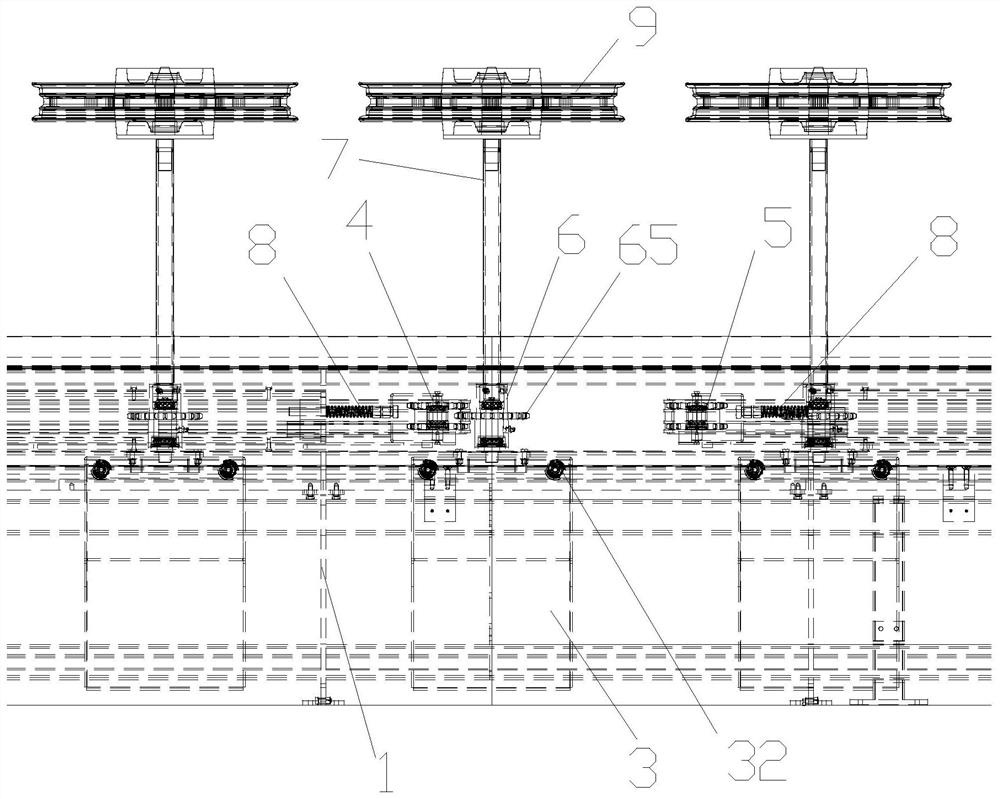

[0022] Embodiment 1: as Figure 1-5 As shown, a kind of autorotation equipment for motorcycle wheel hub coating comprises frame 1, and described frame 1 is the long frame of assembly line type, and frame 1 is provided with guide rail frame 2, and a plurality of trolleys 3 are arranged at intervals and installed on On the guide rail frame 2 and can move horizontally in the frame 1 along the guide rail frame 2, the upper part of the frame 1 is provided with a clockwise rotation power mechanism 4 and an anticlockwise rotation power mechanism 5 successively along the direction of travel of the dolly 3.

[0023] Both sides of the traveling direction of the trolley 3 are provided with vehicle body stabilizing plates 11 mounted on the frame 1; the lower part of the guide rail frame 2 is provided with a lower guide rail groove 21, the middle part is provided with a traction chain groove 22, and the upper part is provided with a strip-shaped The upper guide rail 23; the upper part of t...

Embodiment 2

[0030] Embodiment 2: as Figure 1-4 As shown, a kind of autorotation equipment for motorcycle wheel hub coating comprises frame 1, and described frame 1 is the long frame of assembly line type, and frame 1 is provided with guide rail frame 2, and a plurality of trolleys 3 are arranged at intervals and installed on On the guide rail frame 2 and can move horizontally in the frame 1 along the guide rail frame 2, the upper part of the frame 1 is provided with a clockwise rotation power mechanism 4 and an anticlockwise rotation power mechanism 5 successively along the direction of travel of the dolly 3.

[0031] Both sides of the traveling direction of the trolley 3 are provided with vehicle body stabilizing plates 11 mounted on the frame 1; the lower part of the guide rail frame 2 is provided with a lower guide rail groove 21, the middle part is provided with a traction chain groove 22, and the upper part is provided with a strip-shaped The upper guide rail 23; the upper part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com