Integrated label printing device

A label printing and equipment technology, applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of easy deviation of labels, label ink cannot be dried quickly, and low work efficiency, so as to achieve good drying effect, Prevent deviation and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

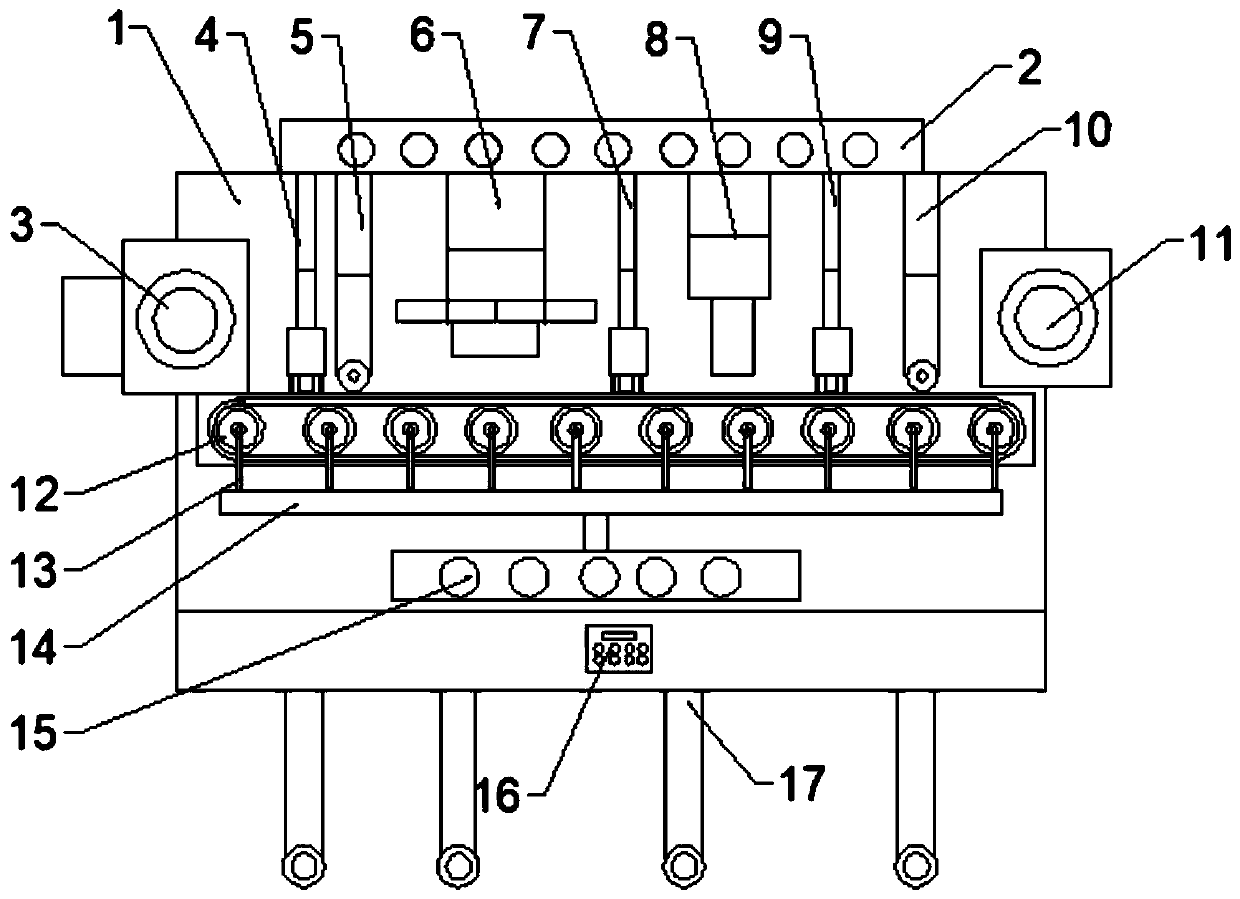

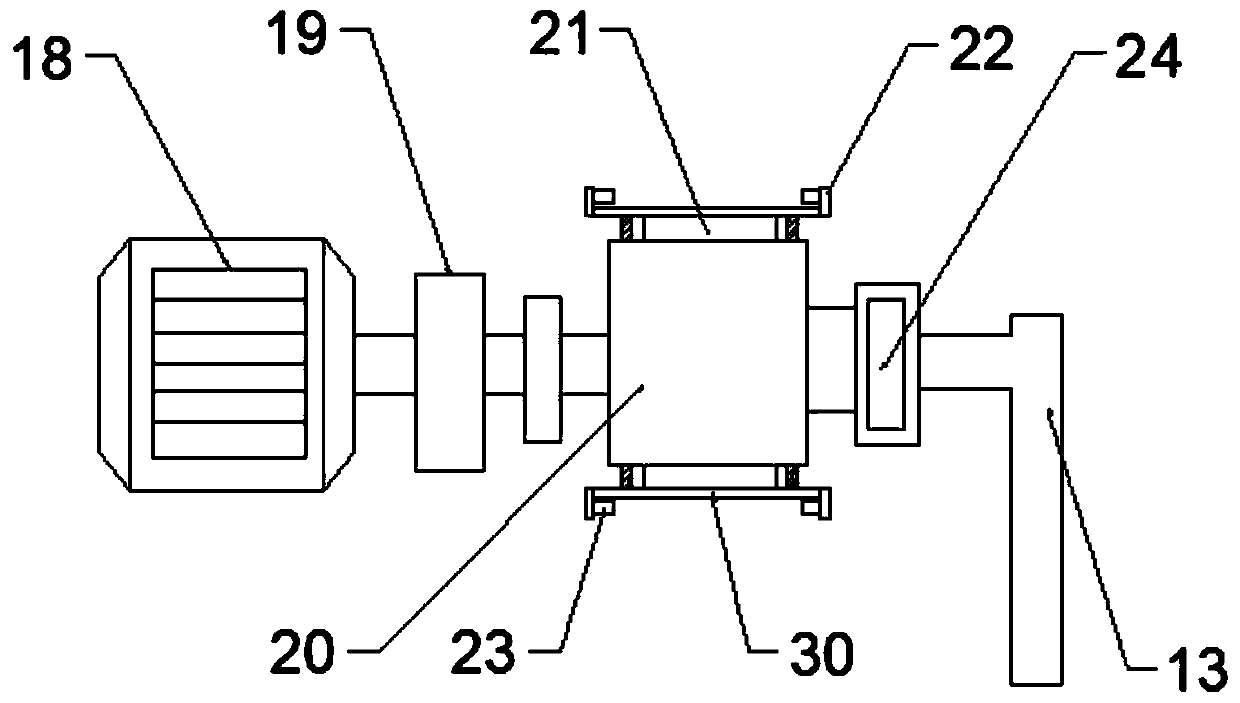

[0023] see Figure 1~3 , in the embodiment of the present invention, an integrated label printing equipment, including a body 1; a No. 1 hot air blower 2 is installed on the top of the body 1; an unwinding mechanism 3 is installed on the left side of the body 1; A winding mechanism 11 is installed on the side; No. 1 dryer 4, No. 1 guiding device 5, printing mechanism 6, No. 2 dryer 7, pressing mechanism 8, and three No. 9 dryer and No. 2 guide 10; the unwinding mechanism 3, printing mechanism 6, pressing mechanism 8 and winding mechanism 11 are prior art; the No. 1 dryer 4 and No. 1 guide 5. There is a transmission mechanism 12 under the printing mechanism 6, the No. 2 dryer 7, the pressing mechanism 8, the No. 3 dryer 9 and the No. 2 guide device 10; the No. 2 hot air blower is installed under the transmission mechanism 12 15; the body 1 is installed on the top of the base; a control panel 16 is installed on the base; a support rod 17 is installed at the bottom of the base. ...

Embodiment 2

[0030] see figure 1 , the bottom end of the support rod 17 is connected to the universal wheel through the lifting device; the universal wheel can enter the inside of the support rod 17 through the lifting device.

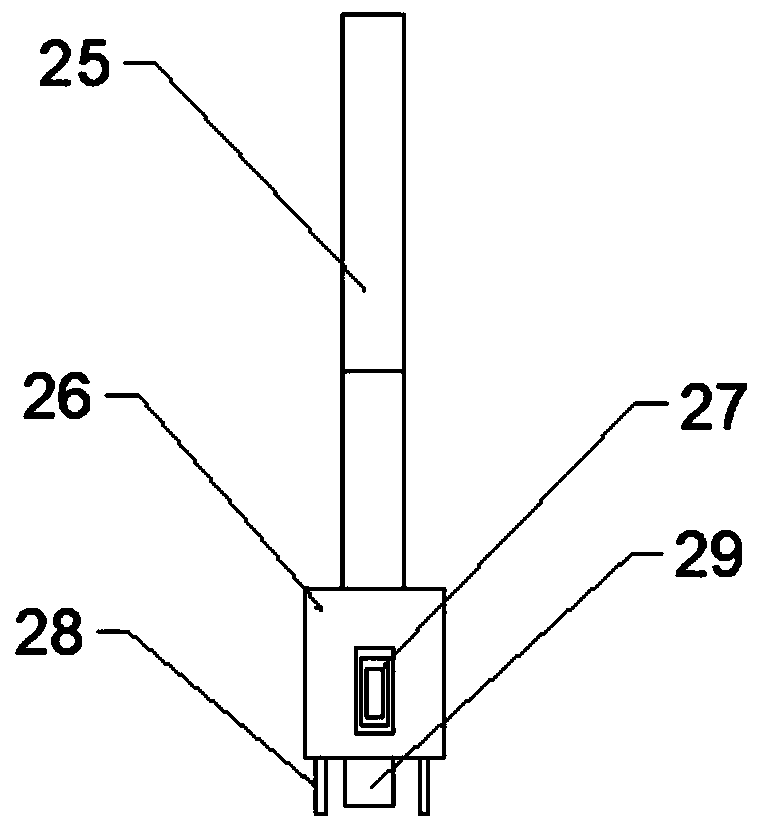

[0031] The working principle of the present invention is: through the setting of several detection probes 28, reduce the moisture measurement error; through the setting of the air outlet 29, the ink on the upper part of the printed matter is dried; the hot air has a downward force on the printed matter, The probability of offset can be reduced; through the setting of the No. 2 dryer 7, the air distribution pipe 13, the clamping device 22, the drying roller 20 and the diffuser hole 21, the bottom of the printed matter is heated to improve the drying efficiency of the ink; through The setting of the clamping device 22 and the fixed block 23 can prevent the printed matter from deviating; the positioning before printing is carried out by the guide roller on the No. 1 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com