Timber saw blade cutting machine

A cutting machine and saw blade technology, applied in the field of wood saw blade cutting machines, can solve the problems of inability to change the horizontal distance, affect the operation performance, and cannot move, so as to reduce the waste of wood resources, reduce the probability of deviation, and have good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

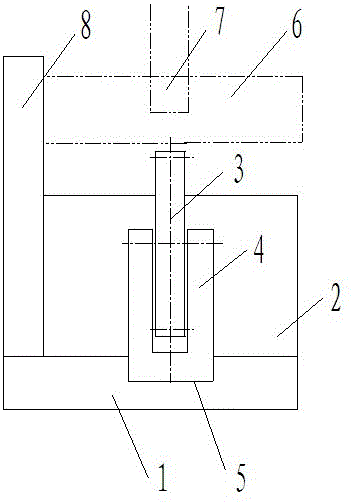

[0008] Such as figure 1 As shown, the wood saw blade cutting machine includes a base 1, an operating platform 2 is arranged on the base 1, a saw blade 3 is arranged on the operating platform, the saw blade 3 is fixed on a bearing frame 4, and the bottom block of the bearing frame is placed on the base Inside the provided chute 5, and move along the direction of the chute 5, the direction of the chute 5 is the same as that of the saw blade 3. The bottom block of the bearing frame slides in the base chute 5, driving the saw blade 3 to move horizontally, thereby adjusting the horizontal distance between the wood 6, the two pressure rollers 7 and the saw blade 3, so that the two pressure rollers 7 are located above the wood Best location.

[0009] One side of the console 2 is also provided with a fixed baffle 8 along the direction of the saw blade, which is used to fix the wood axially and further prevent the wood from twisting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com