Steel aluminum tape slitting system provided with correction devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

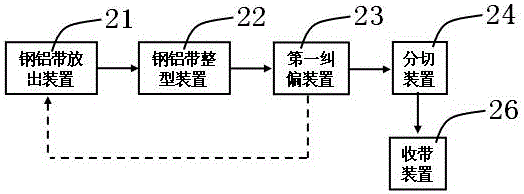

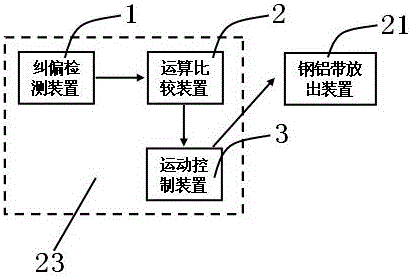

[0023] please see figure 1 , image 3 to Figure 9, a steel and aluminum strip slitting system with a deviation correcting device, comprising a steel and aluminum strip unwinding device 21, a steel and aluminum strip shaping device 22, a cutting device 24, and a tape take-up device 26; it is characterized in that it also has a first deviation correction Device 23, the first deviation correcting device is located between the steel-aluminum strip shaping device 22 and the cutting device 24, the steel-aluminum strip unwinding device 21 releases the finished steel-aluminum strip and transports it to the steel-aluminum strip shaping device 22, the steel-aluminum strip shaping device 22, the steel-aluminum strip shaping device The molded device 22 conveys the steel and aluminum strips released by rollers to achieve surface leveling and sends them to the first deviation correction device 23. The first deviation correction device 23 performs correction processing on the incoming ste...

Embodiment 2

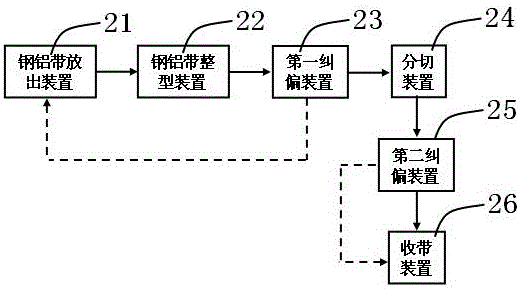

[0025] please see Figure 2 to Figure 9 , a steel and aluminum strip slitting system with a deviation correcting device, comprising a steel and aluminum strip unwinding device 21, a steel and aluminum strip shaping device 22, a cutting device 24, and a tape take-up device 26; it is characterized in that it also has a first deviation correction Device 23 and the second deviation correction device 25, the first deviation correction device is located between the steel and aluminum strip shaping device 22 and the cutting device 24, the second deviation correction device 25 is located between the cutting device 24 and the take-up device 26, the steel and aluminum strip The release device 21 releases the finished steel and aluminum strip and transports it to the steel and aluminum strip shaping device 22, and the steel and aluminum strip shaping device 22 conveys the released steel and aluminum strip through rollers to achieve surface leveling and sends it to the first deviation corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com