Perforating machine for plastic

A punching machine and plastic technology, applied in metal processing, etc., can solve the problems of plastic plate moving back and forth, increasing processing costs, wasting materials, etc., to achieve the effects of reducing processing costs, improving stability, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

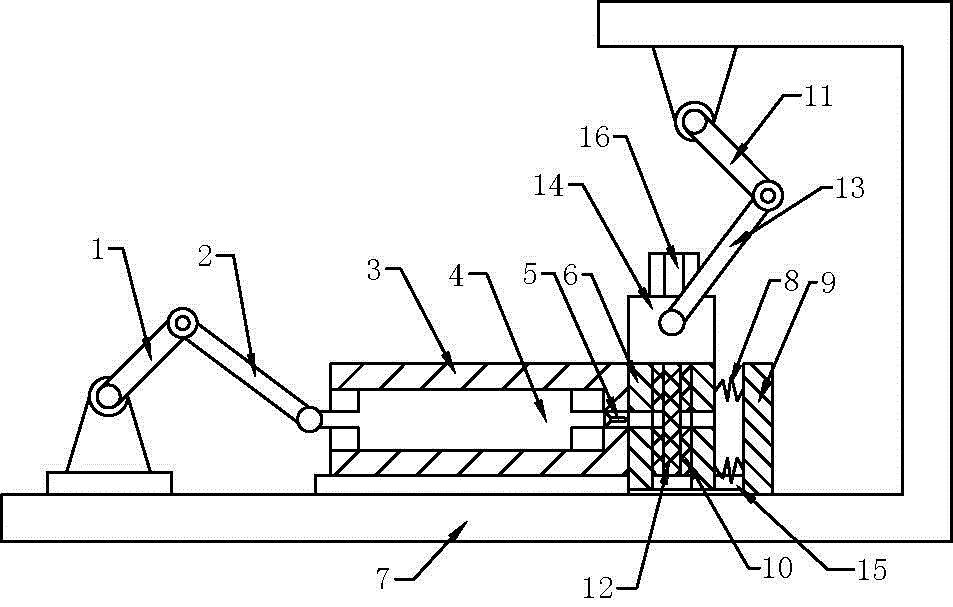

[0015] The reference signs in the drawings of the description include: the first crank 1, the first connecting rod 2, the chute 3, the punching rod 4, the tip 5, the splint 6, the frame 7, the compression spring 8, the fixed block 9, the rubber plate 10. The second crank 11, the plastic plate 12, the second connecting rod 13, the top pressure block 14, the first slide rail 15, and the second slide rail 16.

[0016] Example basic reference figure 1 Shown: a punching machine for plastic, including a frame 7, a punching rod 4, a chute 3 and two splints 6, the chute 3 is welded on the frame 7, and the punching rod 4 is slidably connected to the chute 3 Inside, the left end of the horizontal punching rod 4 is hinged with the first connecting rod 2, and the first connecting rod 2 is hinged with the first crank 1, and the first crank 1 is hinged on the first base welded on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com