Thin-wall shell forming die device with rigid insertion type solid core male die

A thin-walled shell, plug-in technology, used in household components, household appliances, other household appliances, etc., can solve the problems of inaccurate positioning, reduced pressure resistance, inconsistent wall thickness of helmets, etc., to improve production quality and Efficiency, reduce the probability of deviation, and ensure the effect of wall thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

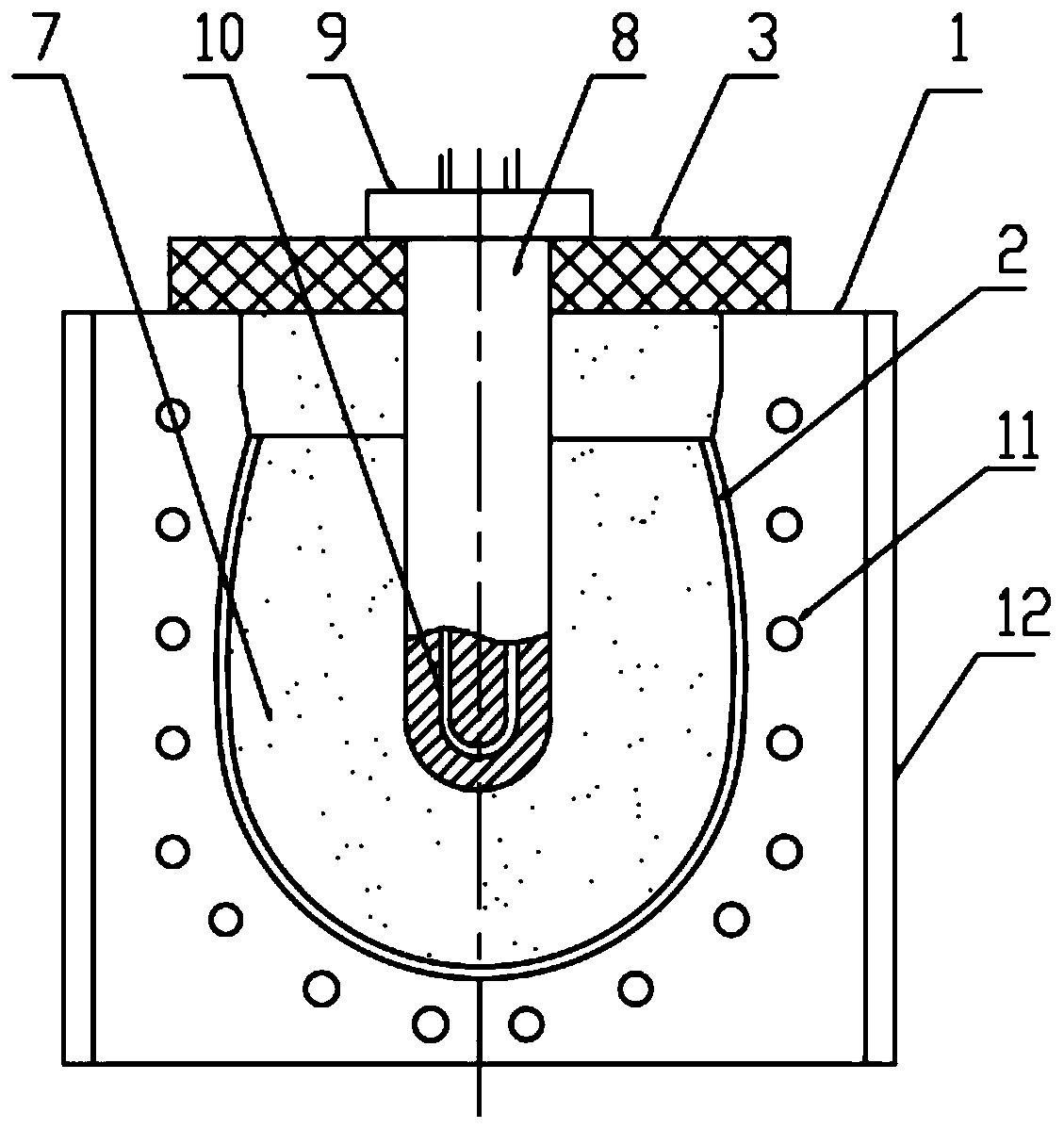

[0030] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

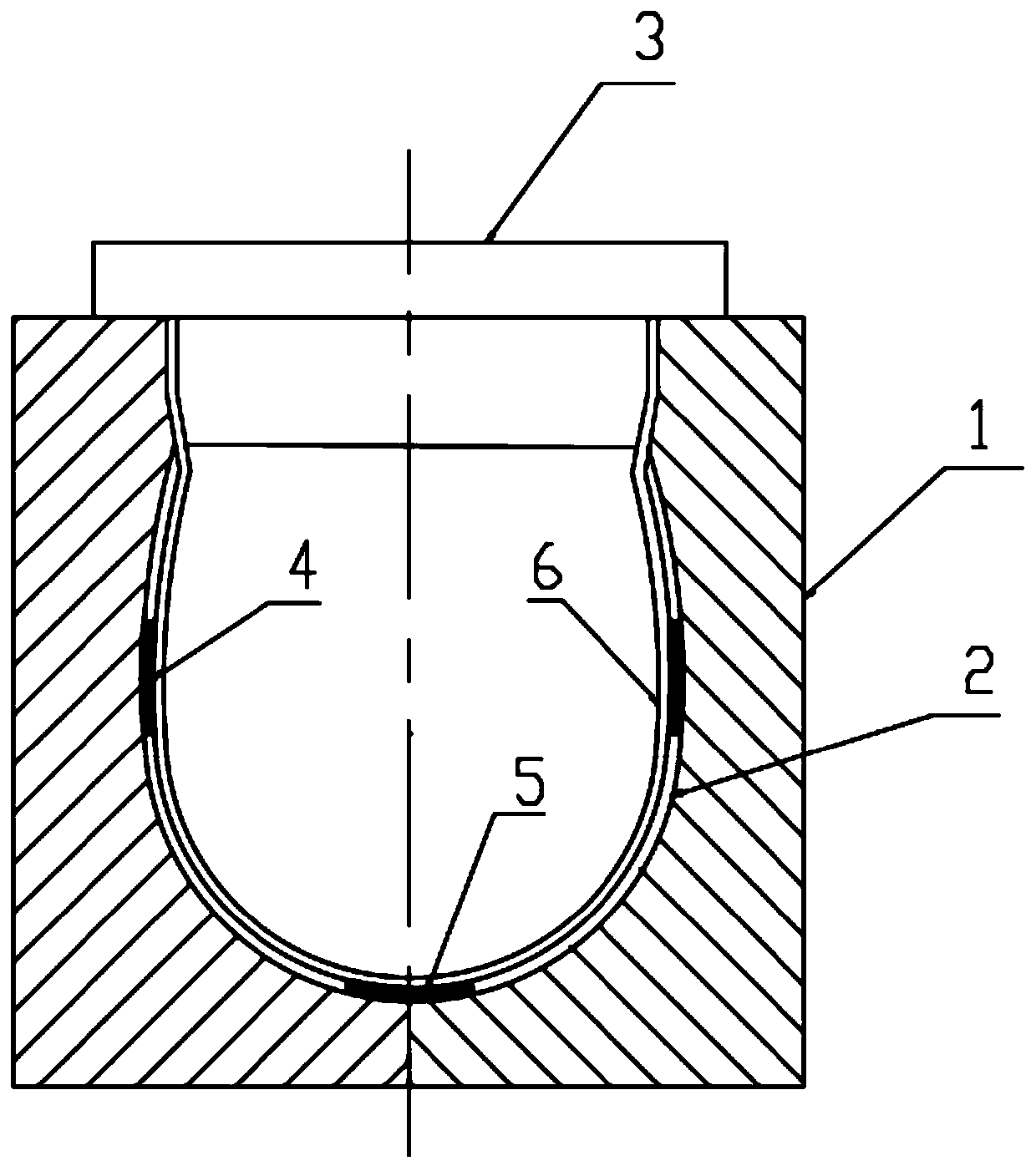

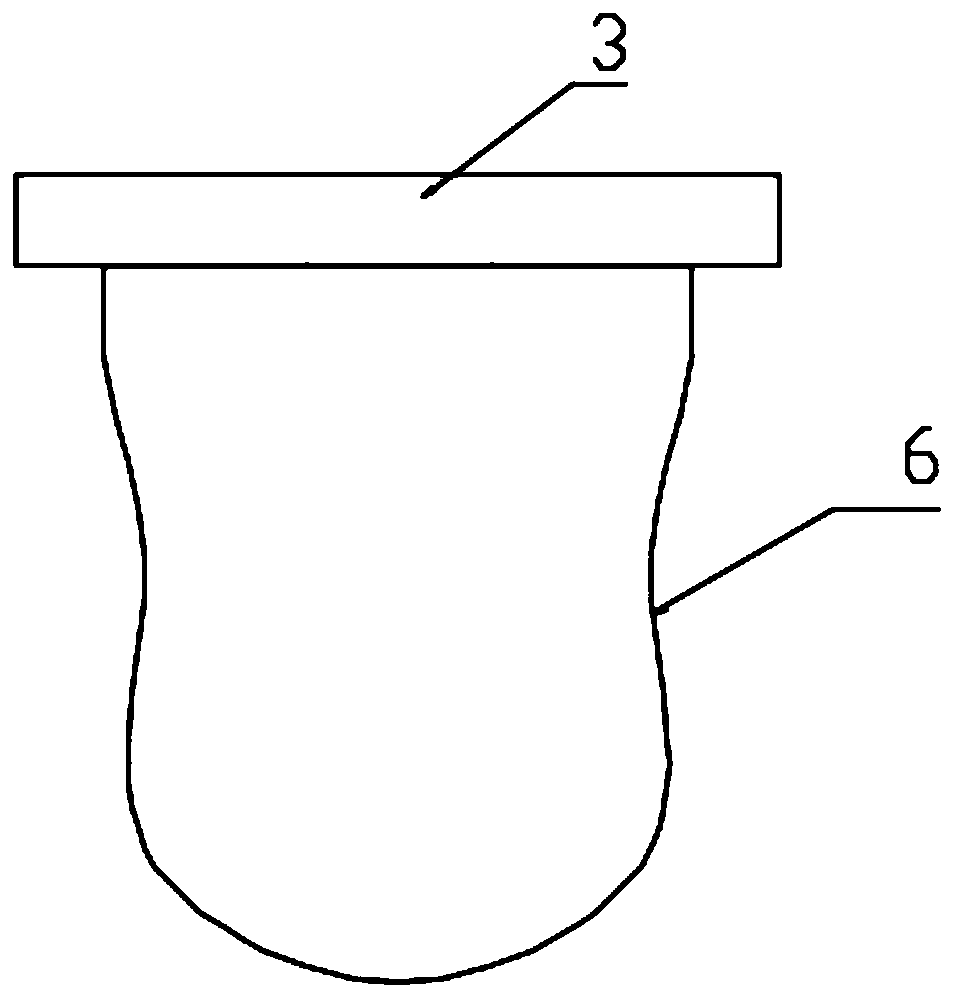

[0031] Such as Figure 3-Figure 9 Shown, the concrete structure of the present invention is:

[0032] A thin-walled shell molding die device with a rigid plug-in solid core male mold, which includes a female mold 1 that is at least divided into two facing parts, and a male mold 7 is arranged in the female mold 1; the outer wall of the male mold 7 is in contact with the A cavity for forming the shell is formed between the inner walls of the female mold 1; the male mold 7 is a solid silicone structure; the male mold 7 is provided with a core for inserting the mandrel 8 and matching the shape of the mand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com