Gadder with safety supporting unit

A technology of safety support and drilling rig, which is applied in the direction of support devices, drilling equipment, directional drilling, etc. It can solve the problems of easy sliding of the lower support structure, blockage of drilling holes, and deviation of drill pipes, etc., so as to increase intelligence and reduce construction costs , The effect of drilling frame stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

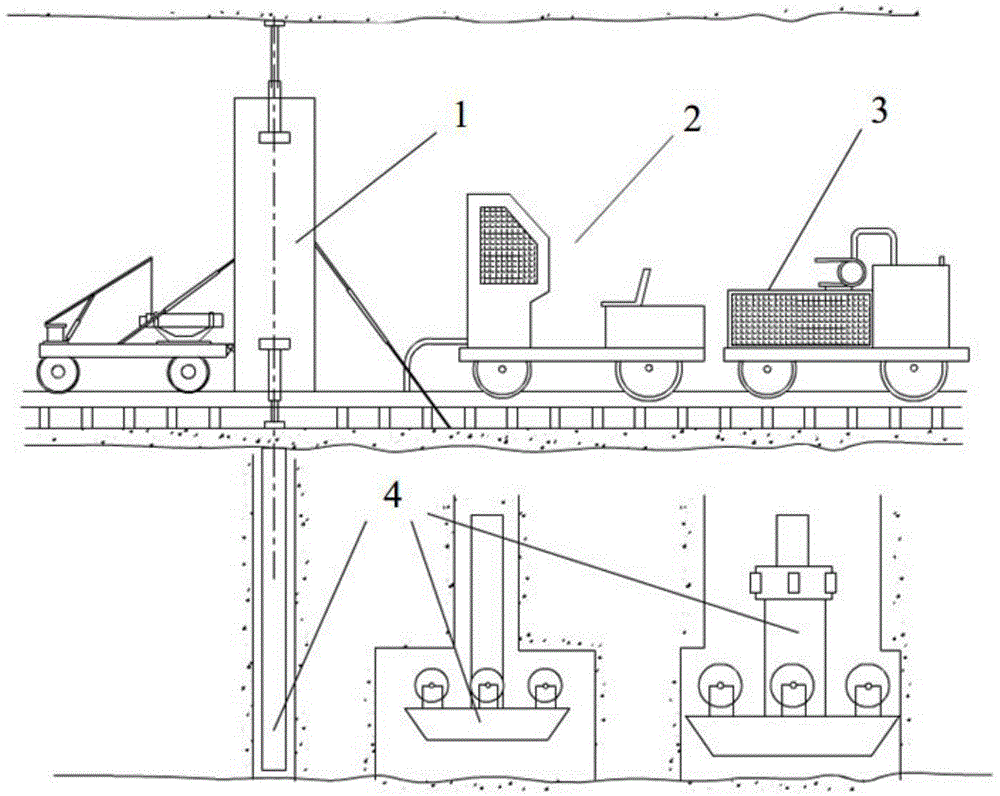

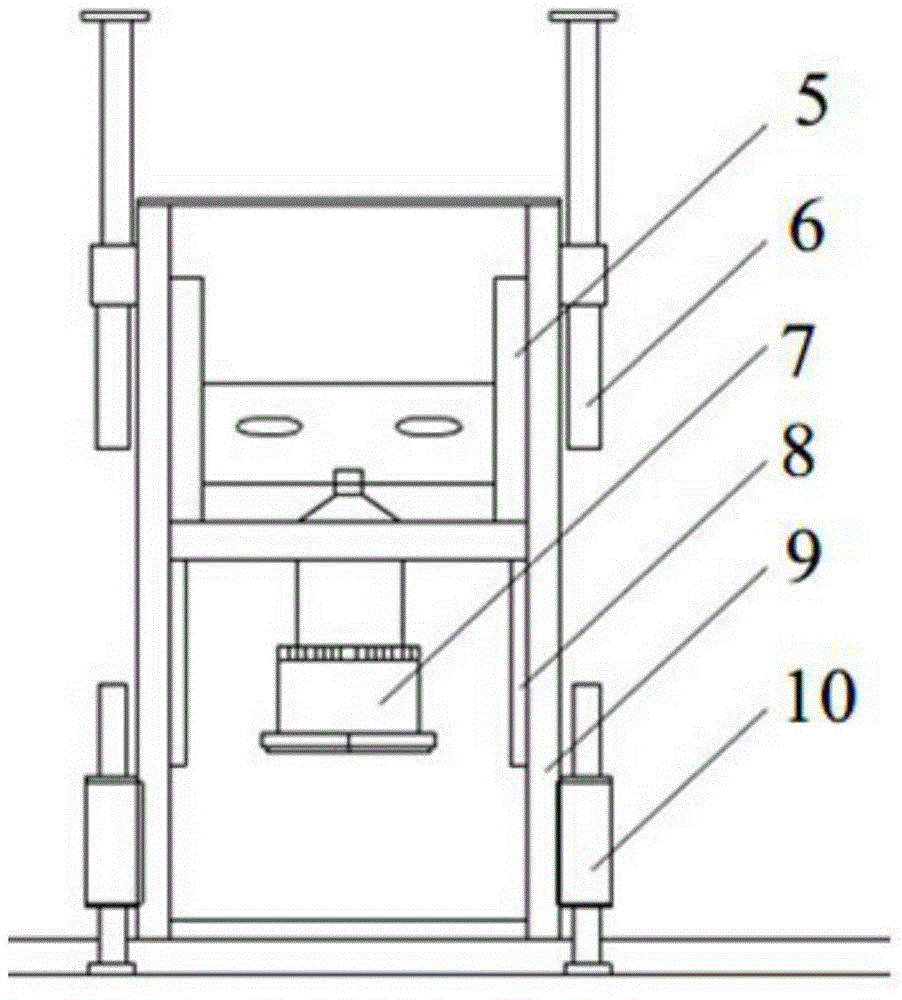

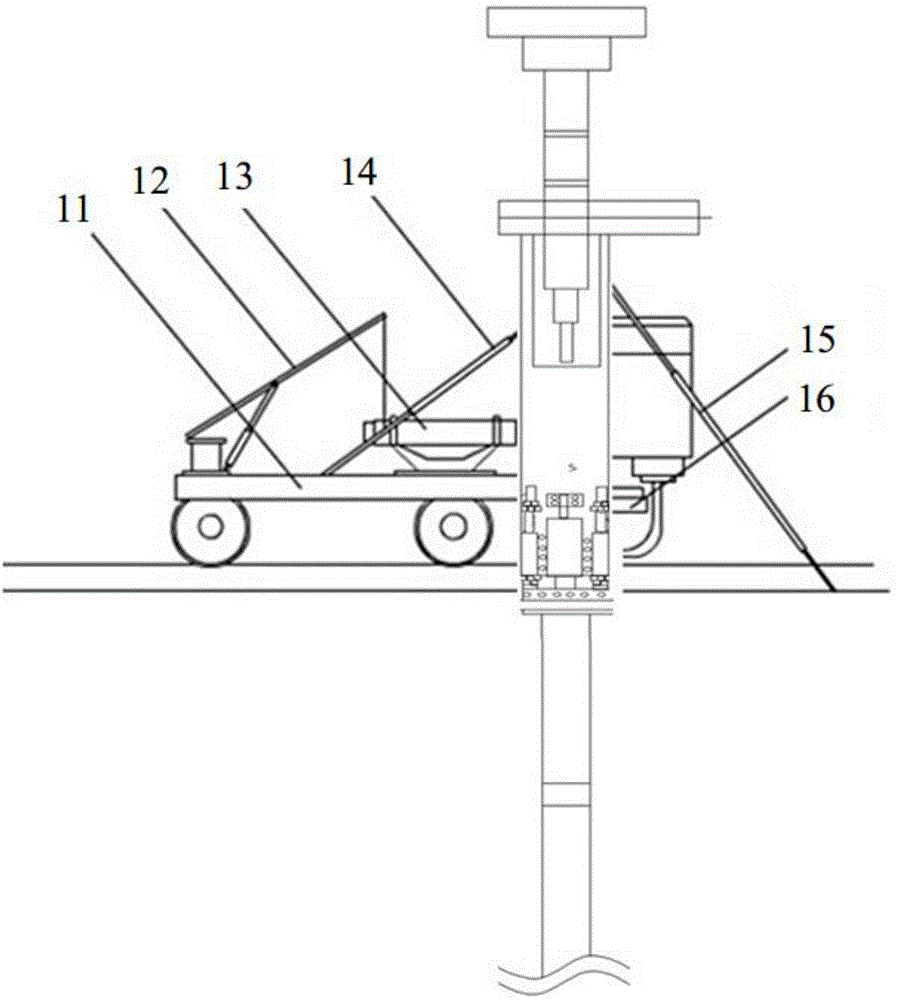

[0032] like figure 1 As shown, the raise drilling machine of the present invention includes a drilling machine car 1, a pump car 3, an operating car 2, a drilling tool 4 and auxiliary tools. like figure 2 and 3 As shown, the drilling rig vehicle 1 is the main engine of the raise drilling rig, and the invention provides a drilling rig vehicle with a safety support device, including a drilling rig flat car 11, a safety support device, a power faucet 7, a main hydraulic cylinder, and a displacement detection component , processing components and an alarm, the safety support device includes a drill frame 9 and hydraulic support legs, the drill frame 9 uses two grooved frames as columns, and the upper and lower cover plates are connected by high-strength bolts, and the two sides of the drill frame 9 are provided with guides rail 8;

[0033] The hydraulic outriggers include two upper hydraulic outriggers 6 and two lower hydraulic outriggers 10, the two upper hydraulic outriggers...

Embodiment 2

[0040] like figure 1 As shown, the raise drilling machine of the present invention includes a drilling machine car 1, a pump car 3, an operating car 2, a drilling tool 4 and auxiliary tools. like figure 2 As shown in Figure 3, the drilling rig 1 is the main engine of the raise drilling rig. The invention provides a drilling rig with a safety support device, including a drilling rig flat car 11, a safety support device, a power faucet 7, and a main hydraulic cylinder. The safety support device includes a drill frame 9 and hydraulic support legs. The drill frame 9 uses two grooved frames as columns, and the upper and lower cover plates are connected by high-strength bolts. Guide rails 8 are arranged on both sides of the drill frame 9;

[0041] like Figure 4 As shown, the hydraulic support legs include two upper hydraulic support legs 6 and four lower hydraulic support legs 10, and the two upper hydraulic support legs 6 are vertically arranged above the drill frame 9 and at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com