Transmission electron microscope high-resolution in-situ suspension type temperature difference pressurization chip and preparation method thereof

A transmission electron microscope, high-resolution technology, used in material analysis using radiation, material analysis using wave/particle radiation, circuits, etc. The effect of temperature difference and pressure function, convenient sample placement, and low sample drift rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

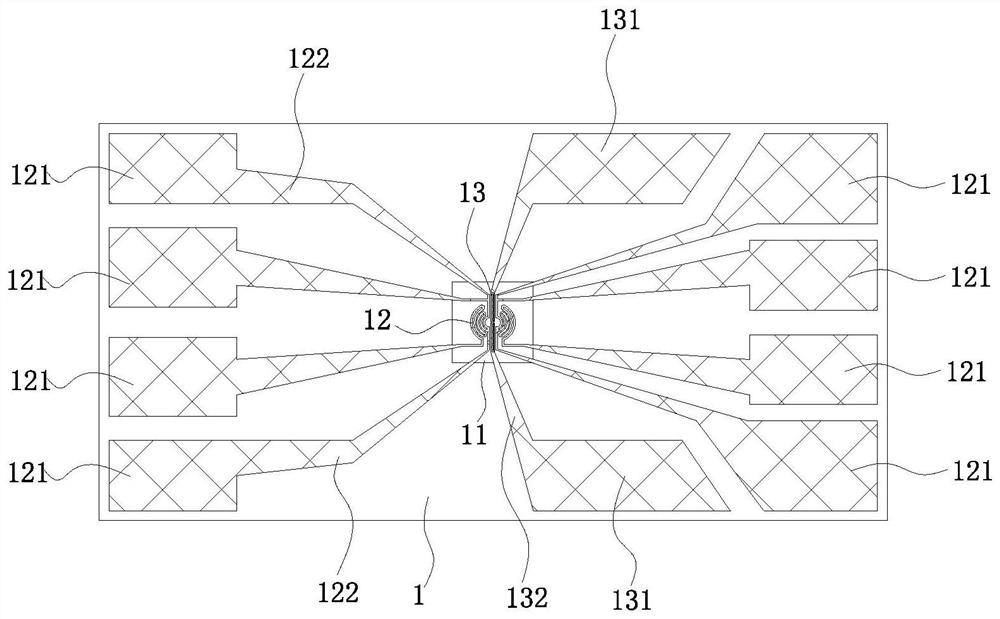

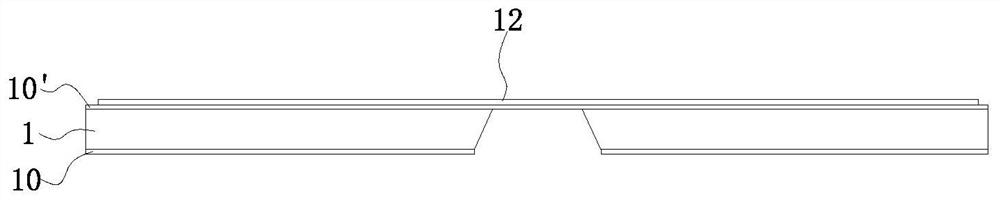

[0031] like Figure 1-Figure 3 As shown, this embodiment provides a TEM high-resolution in-situ suspended temperature difference pressurized chip, which includes a substrate 1 covered with an insulating layer 10 on the front and back of the substrate 1 . Wherein, the substrate in this embodiment is a silicon substrate, and the insulating layer is a silicon nitride or silicon oxide insulating layer.

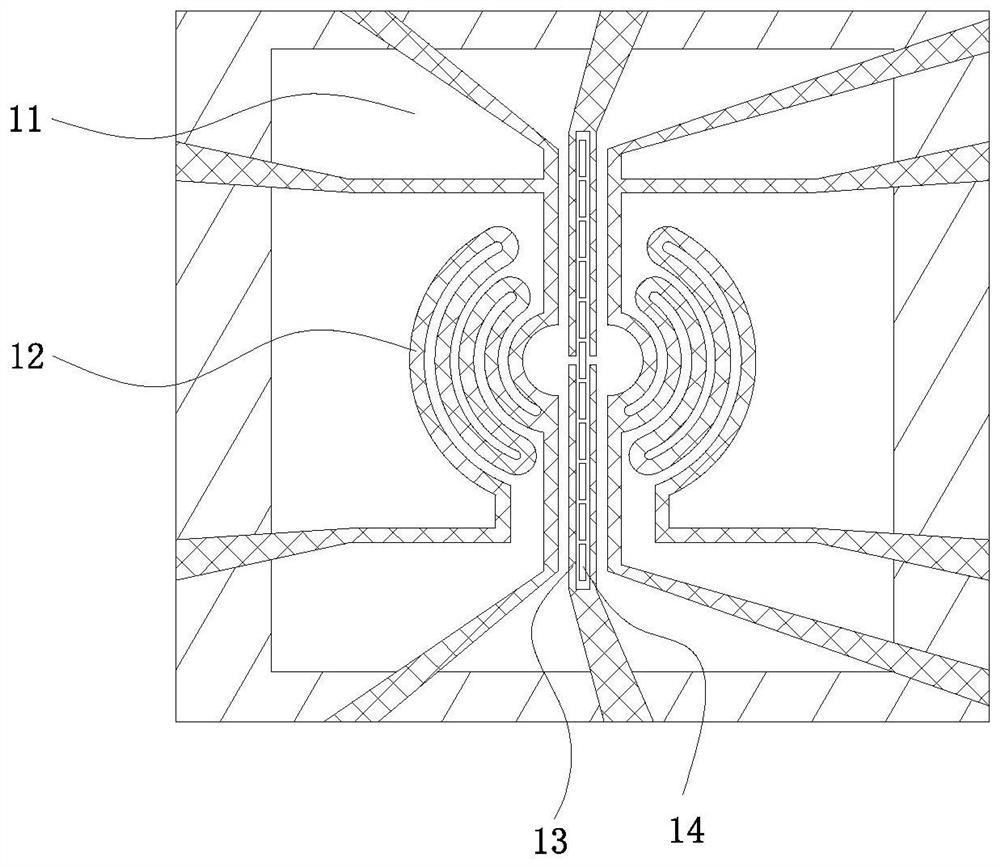

[0032] There is a central window 11 in the middle of the substrate 1, the central window 11 is suspended, and the central window 11 is covered with a support layer 10', the support layer 10' is a silicon nitride layer or a silicon oxide layer.

[0033] The supporting layer in the central window 11 has two symmetrical heating wires 12 and two pressure circuits 13 symmetrically arranged up and down, and the two pressure circuits 13 are located in the gap between the two heating wires 12 .

[0034] Wherein, the heating wire 12 is a spiral circular arc heating wire, there is a gap be...

Embodiment 2

[0045]This embodiment provides a method for preparing a high-resolution transmission electron microscope in-situ suspended temperature difference pressurized chip, which includes the following steps:

[0046] S1. Prepare a Si(100) wafer A with silicon nitride or silicon oxide layers on both sides, the thickness of the silicon nitride or silicon oxide layer is 0.5-5um, and the thickness of the silicon wafer is 50-500um;

[0047] S2. Using the photolithography process, transfer the central window pattern from the photolithography mask to any side of the above-mentioned wafer A, use this as the back side, and then develop it in a positive photoresist developer to obtain wafer A-1;

[0048] Preferably, the photolithography process is exposed under the hard contact mode of the ultraviolet lithography machine; the photoresist used in the photolithography process is AZ5214E; the developing time is 65s;

[0049] More preferably, the exposure time is 20s;

[0050] S3. Using reactive i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com