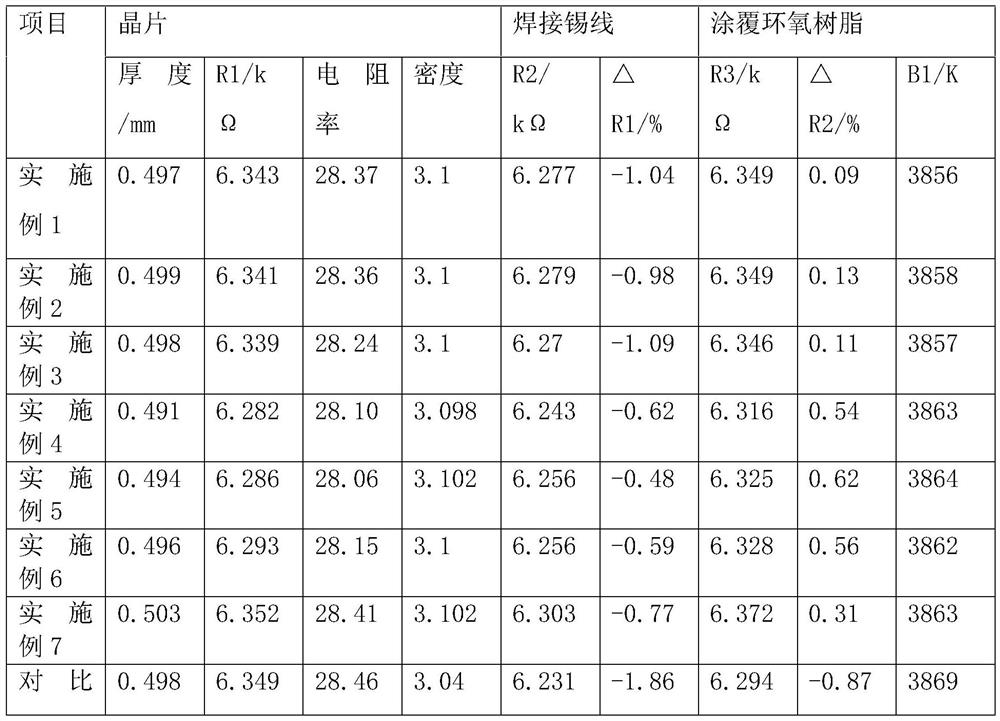

Negative temperature coefficient thermistor chip and preparation method thereof

A thermistor chip and negative temperature coefficient technology, which is applied in the direction of resistors with negative temperature coefficient, manufacturing resistor chips, resistance manufacturing, etc., can solve the problem of unstable resistance value of thermistor at room temperature, insufficient chip thickness and density , R value and B value drift and other issues, to achieve the effect of preventing resistance drift or even failure, small resistance drift and high B value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-5

[0051] The polyethersulfone resin in Preparation Example 1-5 is selected from Dongguan Chengyi Plastic Co., Ltd., the brand is BASF E2010 of Germany, and the nano-aluminum nitride powder is selected from Ningbo Jinlei Nano Material Technology Co., Ltd., the model is JL-AIN, and the particle size is The polyvinylpyrrolidone is 40nm, and the polyvinylpyrrolidone is selected from Shanghai Haoru Industrial Development Co., Ltd., the model is K30.

preparation example 1

[0052] Preparation Example 1: Mix 40kg of glass powder with 20kg of polyethersulfone resin, 2kg of polyvinylpyrrolidone, melt, extrude, granulate, pulverize, and pass through a 300-mesh sieve to make glass powder particles, and then mix with 20kg of silver nitrate aqueous solution, 4kg concentration is 5% formaldehyde solution and 5kg concentration is 2% sodium dodecylbenzenesulfonate solution, stir evenly, filter, wash, dry, make silver-coated glass powder, the concentration of silver nitrate aqueous solution is 0.02g / moL, the glass powder is made by the following method: 5kg SiO 2 、5.5kgBi 2 o 3 , 5kg ZnO, 2kg B 2 o 3 、4kg V 2 o 5 , 1kg Na 2 O is placed in a crucible, heated and melted at 1300°C to form a hot liquid, then 2kg of nano-aluminum nitride powder is added, stirred evenly, vacuum defoaming, the vacuum degree is 0.13MPa, and the defoaming time is 7 minutes. Quenching, ball milling, passing through a 300-mesh sieve, mixing with sodium fluoride with a concentr...

preparation example 2

[0053] Preparation Example 2: Mix 45kg of glass powder with 25kg of polyethersulfone resin, 3kg of polyvinylpyrrolidone, melt, extrude, granulate, pulverize, and pass through a 300-mesh sieve to make glass powder particles, and then mix with 25kg of silver nitrate aqueous solution, 5kg concentration is 25% formaldehyde solution and 6kg concentration is 20% sodium dodecylbenzene sulfonate solution, stir well, filter, wash, dry, make silver-coated glass powder, the concentration of silver nitrate aqueous solution is 0.04g / moL, the glass powder is made by the following method: 8kg SiO 2 、6kgBi 2 o 3 , 8kg ZnO, 2.5kg B 2 o 3 、6kg V 2 o 5 , 1.5kg Na 2 O is placed in a crucible, heated and melted at 1350°C to form a hot liquid, then 2.5kg of nano-aluminum nitride powder is added, stirred evenly, vacuum defoaming, the vacuum degree is 0.07MPa, and the defoaming time is 10 minutes. Water quenching, ball milling, passing through a 300-mesh sieve, mixing with sodium fluoride wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com