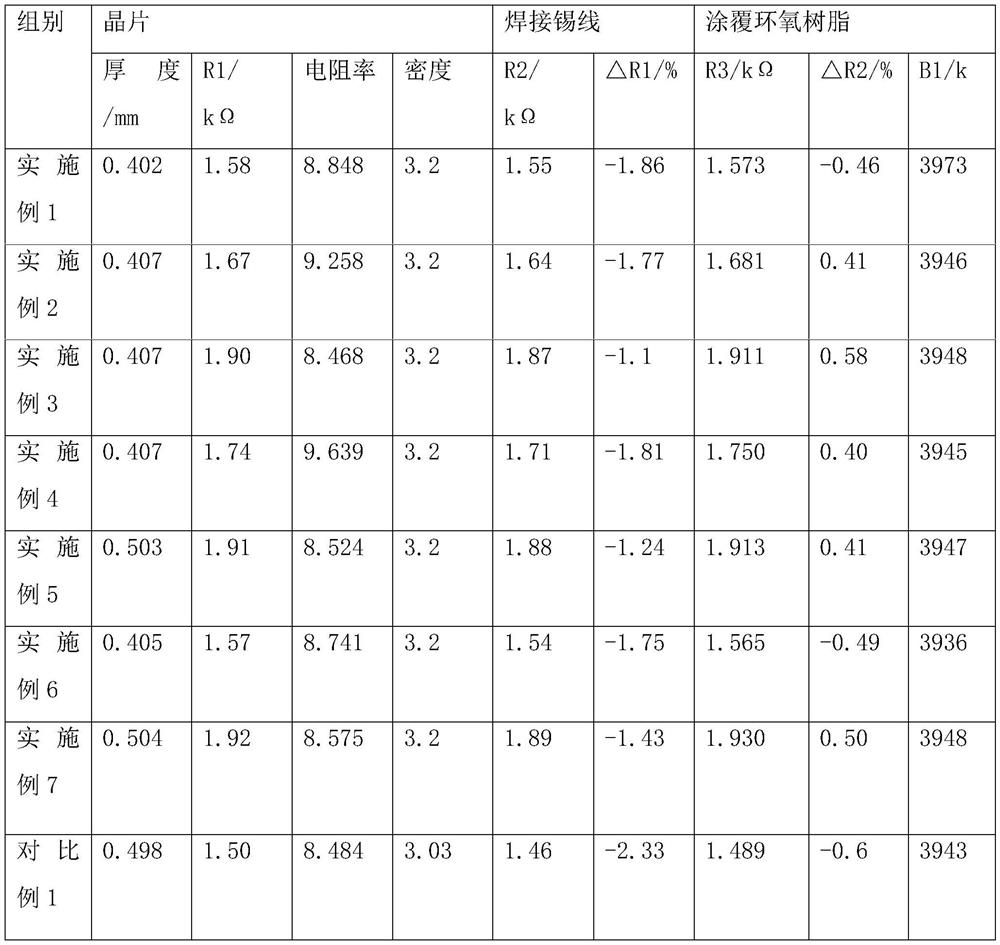

A kind of NTC thermistor chip and preparation method thereof

A thermistor chip and wafer technology, applied in the direction of resistors, resistor components, non-adjustable metal resistors, etc., can solve problems affecting service life and stability, R value and B value drift, etc., to achieve good resistance High temperature oxidation, high B value, uniform particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0053] Preparation Example 1: Put cobalt oxalate in a zirconia sagger, place the zirconia sagger in a muffle furnace, heat from room temperature to 800°C for 9 hours, then raise the temperature to 850°C for 40 minutes, Insulate at 850°C for 40min and cool to below 75°C to prepare Co 3 o 4 .

preparation example 2

[0054] Preparation Example 2: Put cobalt oxalate in a zirconia sagger, put the zirconia sagger in a muffle furnace, heat from room temperature to 800°C for 8.5 hours, then raise the temperature to 850°C for 35 minutes , kept at 850°C for 35min, and cooled to below 75°C to obtain Co 3 o 4 .

preparation example 3

[0055] Preparation Example 3: Put cobalt oxalate in a zirconia sagger, put the zirconia sagger in a muffle furnace, heat from room temperature to 800°C for 8 hours, then raise the temperature to 850°C for 30 minutes, Insulate at 850°C for 30min, cool to below 75°C to prepare Co 3 o 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com