Method for controlling cracks of double-block type ballastless track bed slabs

A control method and technology of ballastless track, applied in the direction of track, road, ballast layer, etc., to achieve the effect of cost saving, improvement of crack occurrence and improvement of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

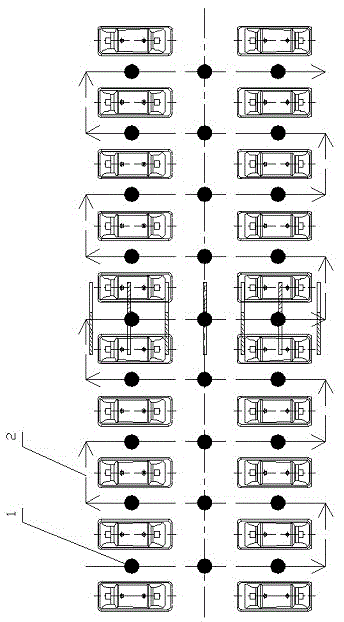

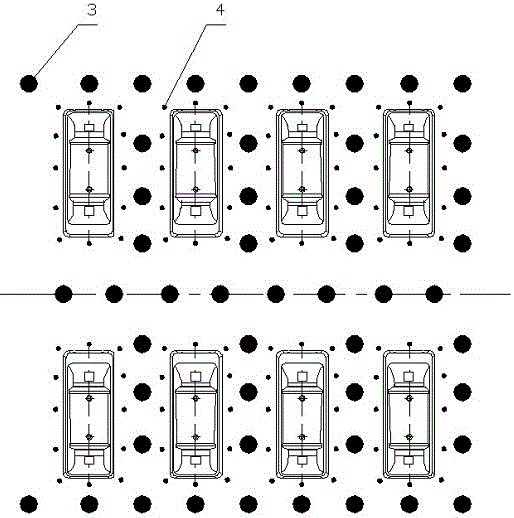

Image

Examples

Embodiment

[0039] 1. Concrete pouring technology

[0040] Before concrete pouring, the supporting layer and sleepers should be moistened to ensure that the supporting layer and sleepers are completely wet, and there should be no obvious water accumulation. If the concrete is not wetted with water, the concrete will lose water at the contact position between the concrete and the supporting layer and the sleeper, resulting in inconsistent shrinkage of the concrete in the early stage. Cracks occur. In order to reduce excessive vibration, the concrete of the track bed slab cannot be poured at one point, and the vibrator is used to drive the material, but should be poured back and forth between the double-block sleepers in a zigzag route, otherwise the concrete on the surface of the track bed slab after pouring will segregate and appear laitance , resulting in inconsistent shrinkage and cracks.

[0041] 2. Concrete vibration technology

[0042] During the concrete pouring process of the dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com