Testing and calibration integrated working table for automatic hole making system and calibration method of testing and calibration integrated working table

An automatic manufacturing and workbench technology, applied in the direction of workbench, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to realize system error compensation, lack of measurement system calibration function, etc., to ensure accuracy and improve normal accuracy , Improve the effect of position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

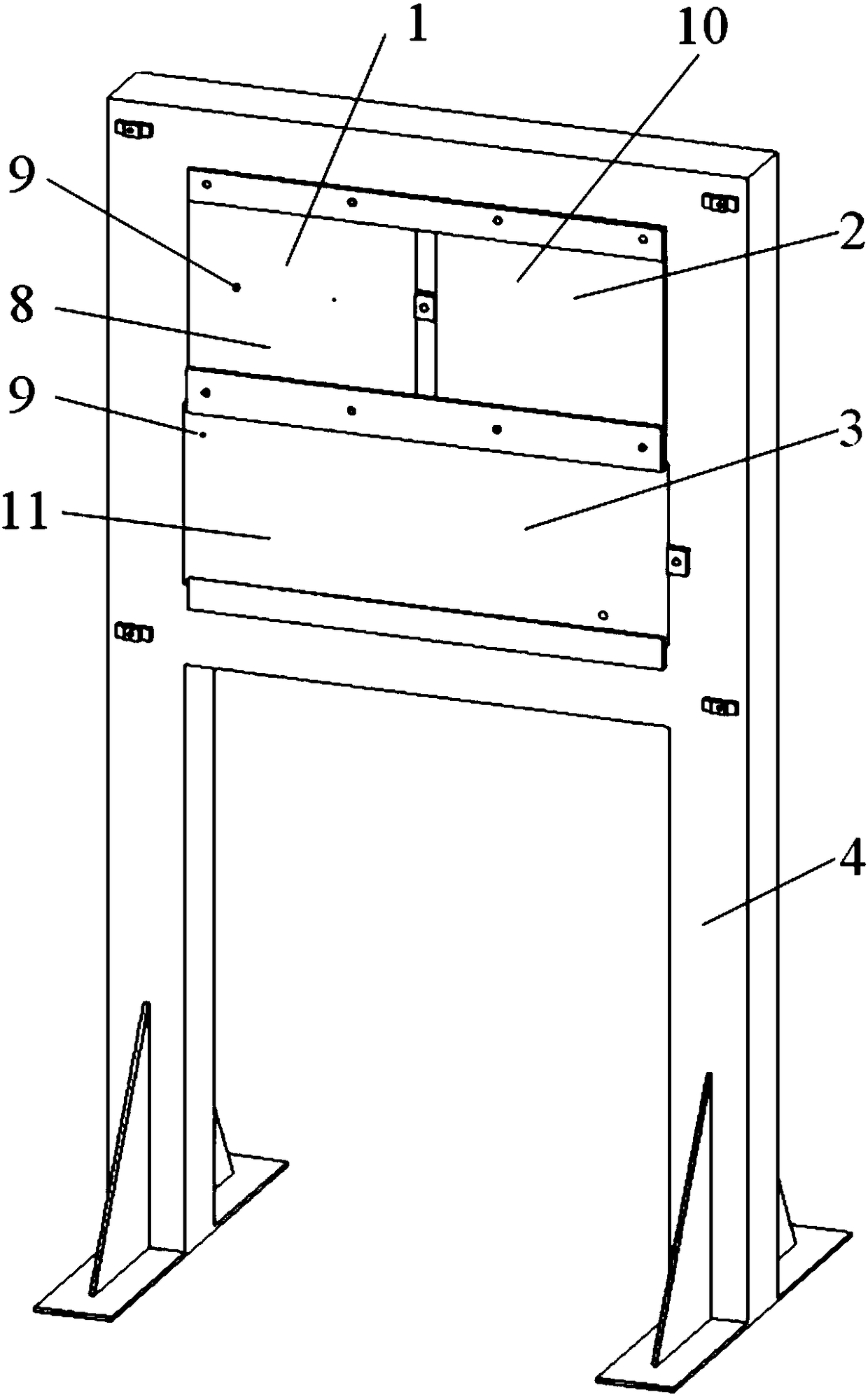

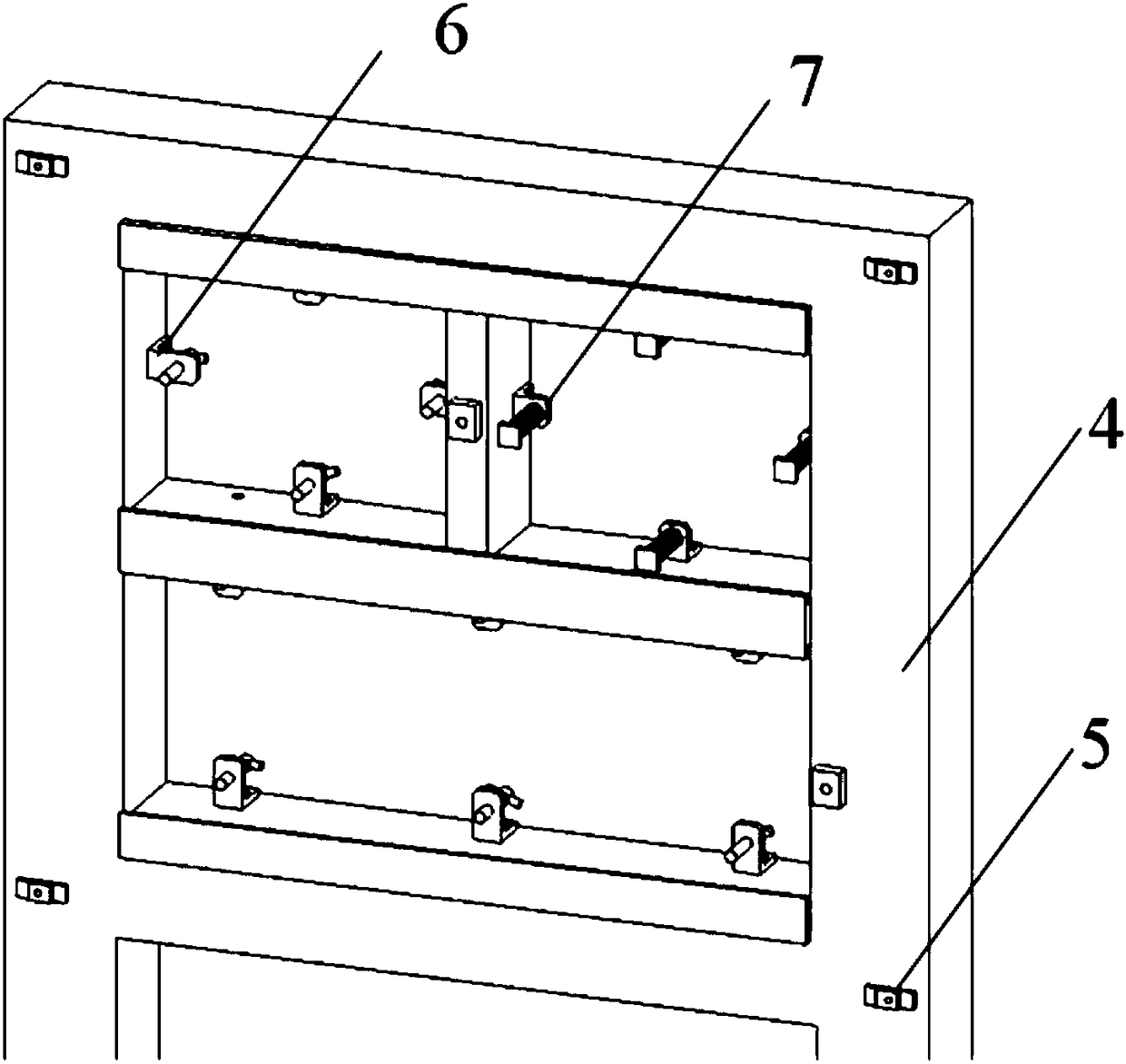

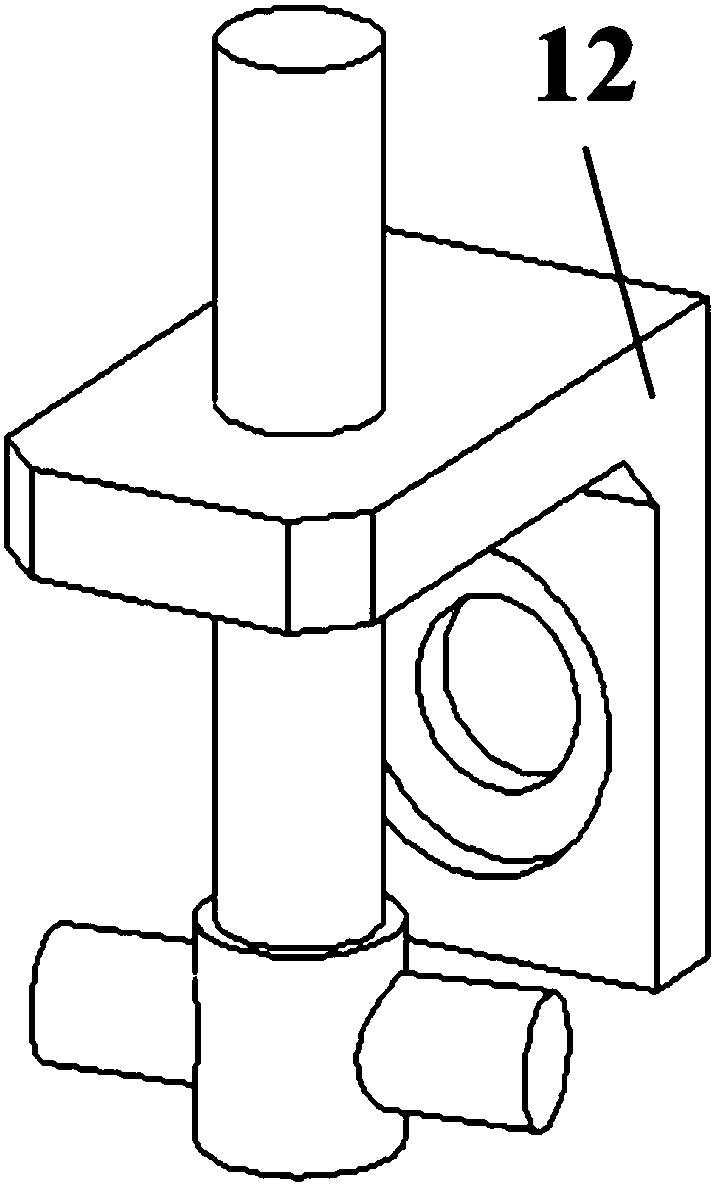

[0035] An integrated workbench for test calibration of an automatic hole-making system according to the present invention, the schematic diagram of which is shown in 1 and figure 2 As shown, it includes a column frame 4. The column frame 4 is divided into upper and lower layers. A partition is fixed in the middle of the upper layer. A visual camera calibration module 1 is placed on one side of the partition. The visual camera calibration module 1 includes a clamping assembly through bolts. 6 The alignment test plate 8 fixed between the side wall of the column frame 4 and the partition, the alignment nail 9 is fixed on the side of the surface of the alignment test plate 8, and the normal sensor calibration module is installed on the other side of the partition 2. The normal direction sensor calibration module 2 includes a standard flat panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com