Manufacturing method of plug-in terminal of connector

A manufacturing method and connector technology, applied in the field of electronics, can solve the problems of difficult to guarantee coplanarity, many processes, easy bending and deformation, etc., and achieve the effects of improving production efficiency, reducing manufacturing cost, and improving position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

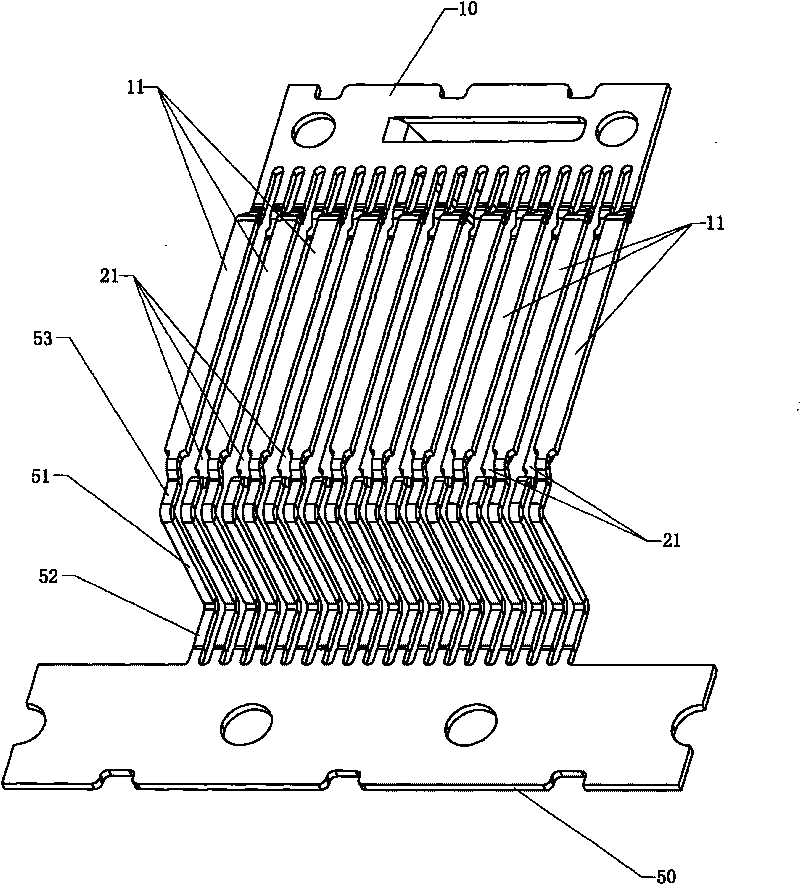

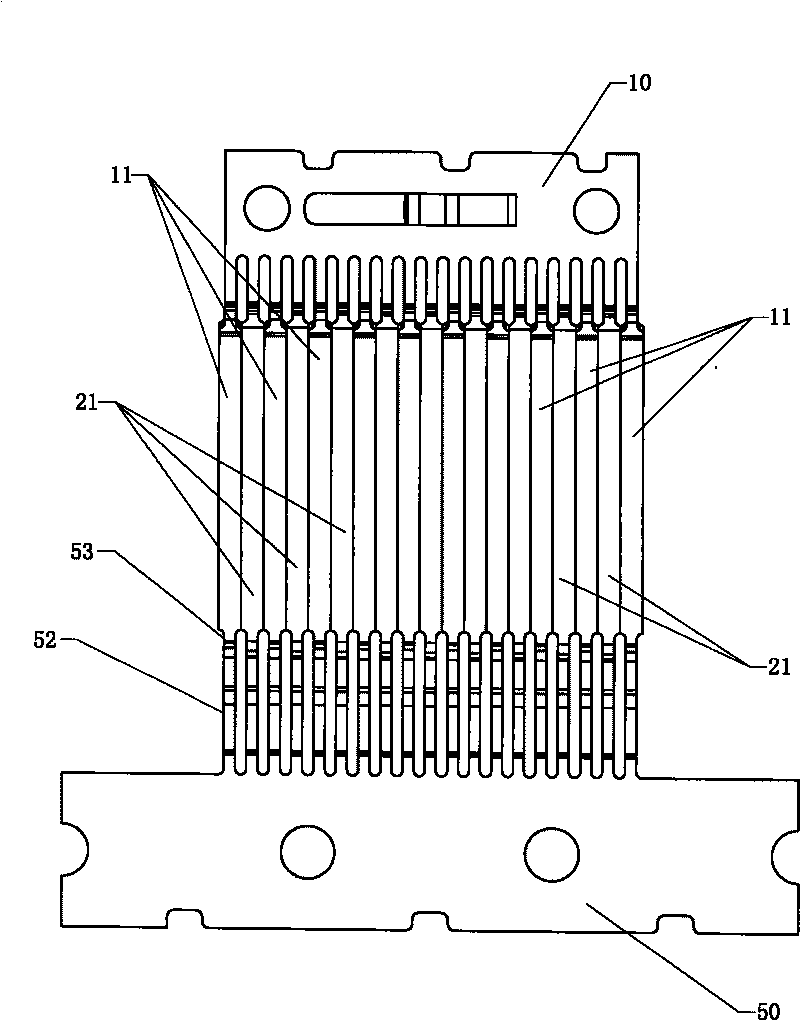

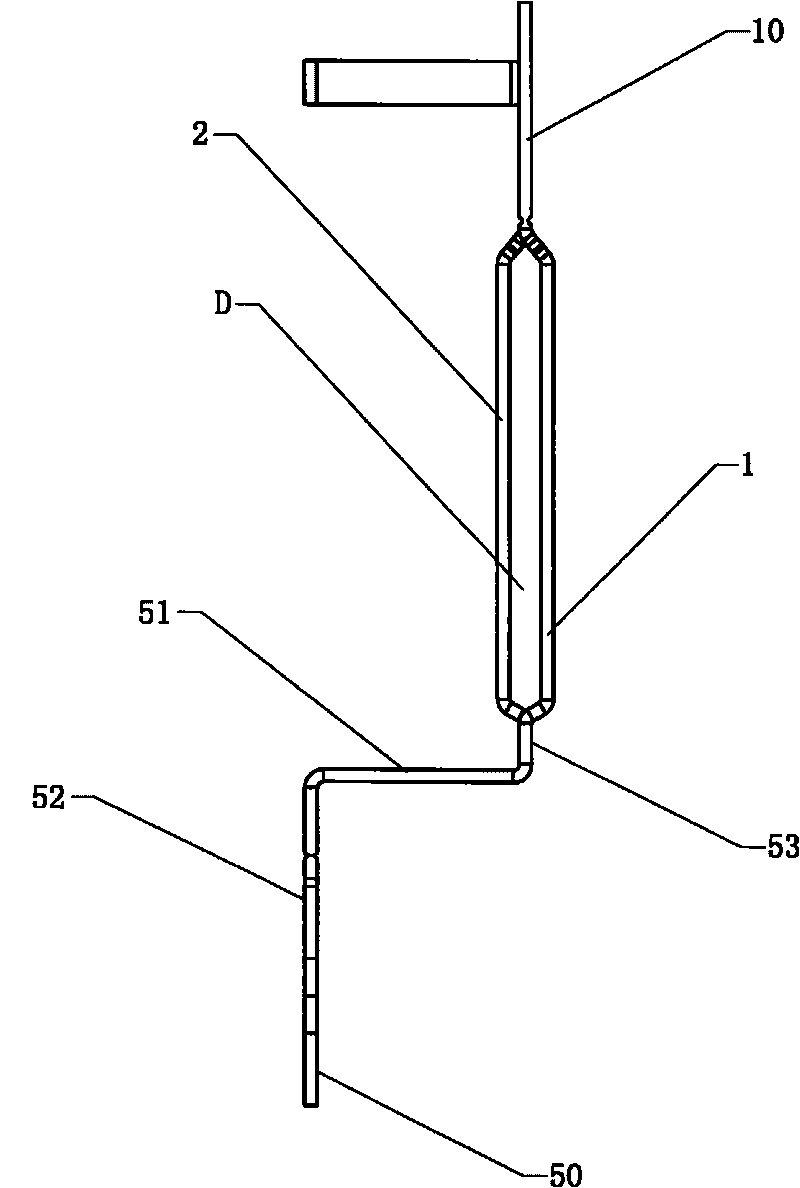

[0035] Figure 1-Figure 10 A specific embodiment of the invention is shown.

[0036] In this embodiment, the manufacturing method of the plug-in terminal of the connector includes the following steps:

[0037]a. Form the first row of conductive terminals 1 (including several conductive terminals 11) and the second row of conductive terminals 2 (including several conductive terminals 21) of connector insertion terminals on the metal strip, the first row of conductive terminals 1 and the second row of conductive terminals One end of the row of conductive terminals 2 is connected through the front connecting strip 10, and the other end is connected through the rear connecting strip 50;

[0038] At the front end, along the thickness direction of the metal strip (see image 3 , image 3 The horizontal direction in is the thickness direction of the metal strip, that is, the thickness direction of the first row of conductive terminals 1 and the second row of conductive terminals 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com