Automatic feeding mechanism for loading circuit boards and blanks on stacked trays

A technology of automatic feeding and circuit boards, which is applied in the direction of conveyor objects, transportation and packaging, etc., to achieve high handling efficiency and improve the effect of position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

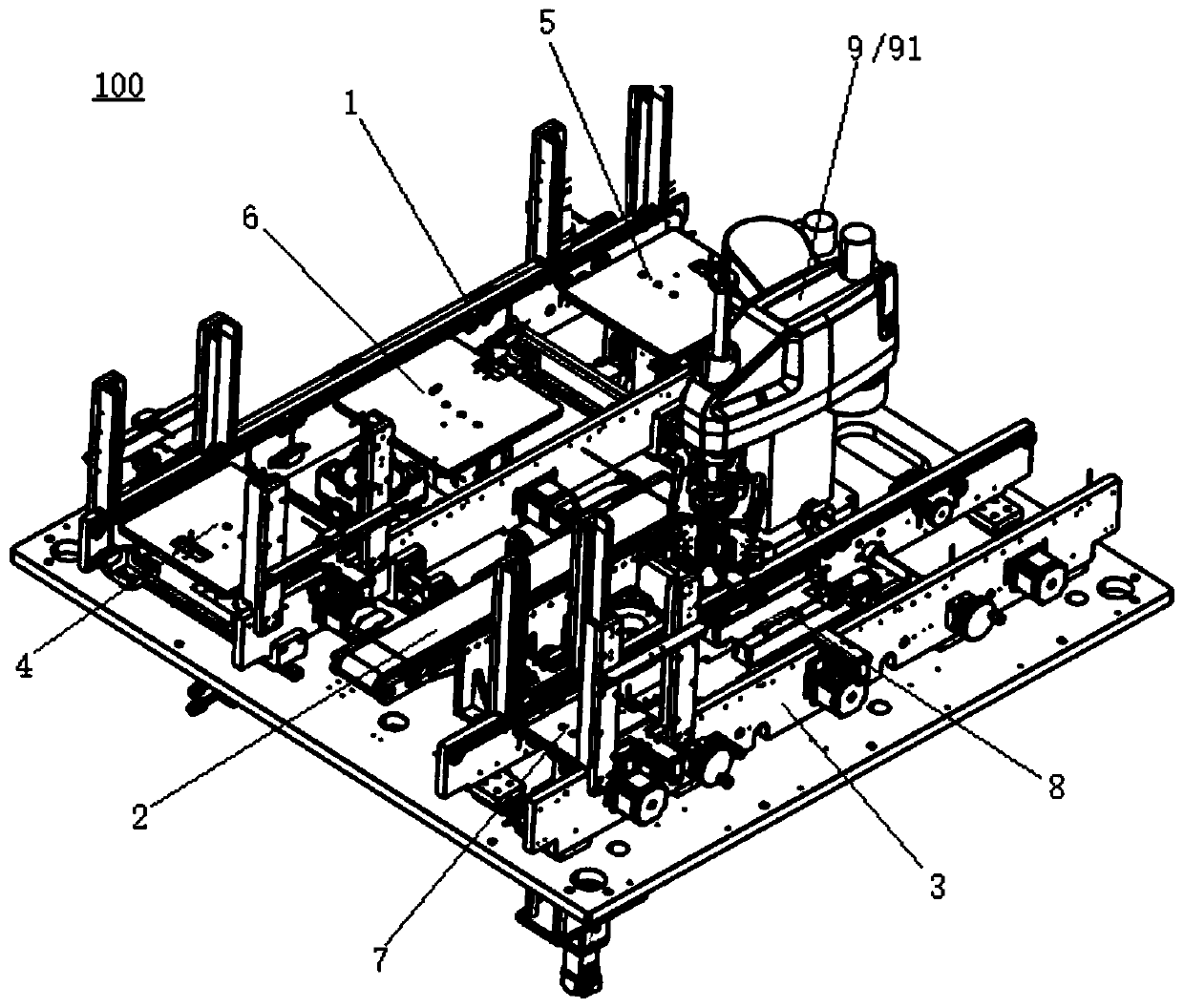

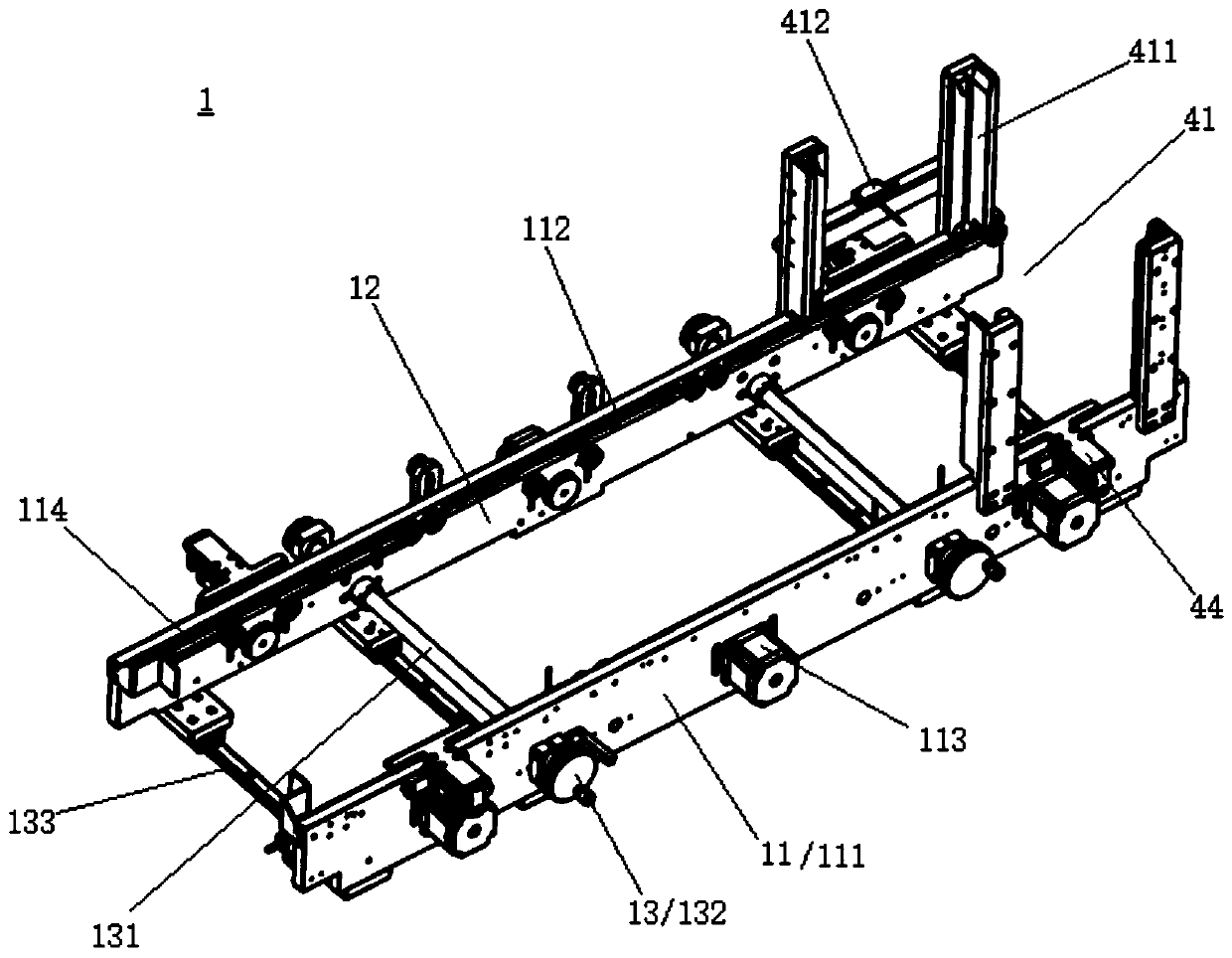

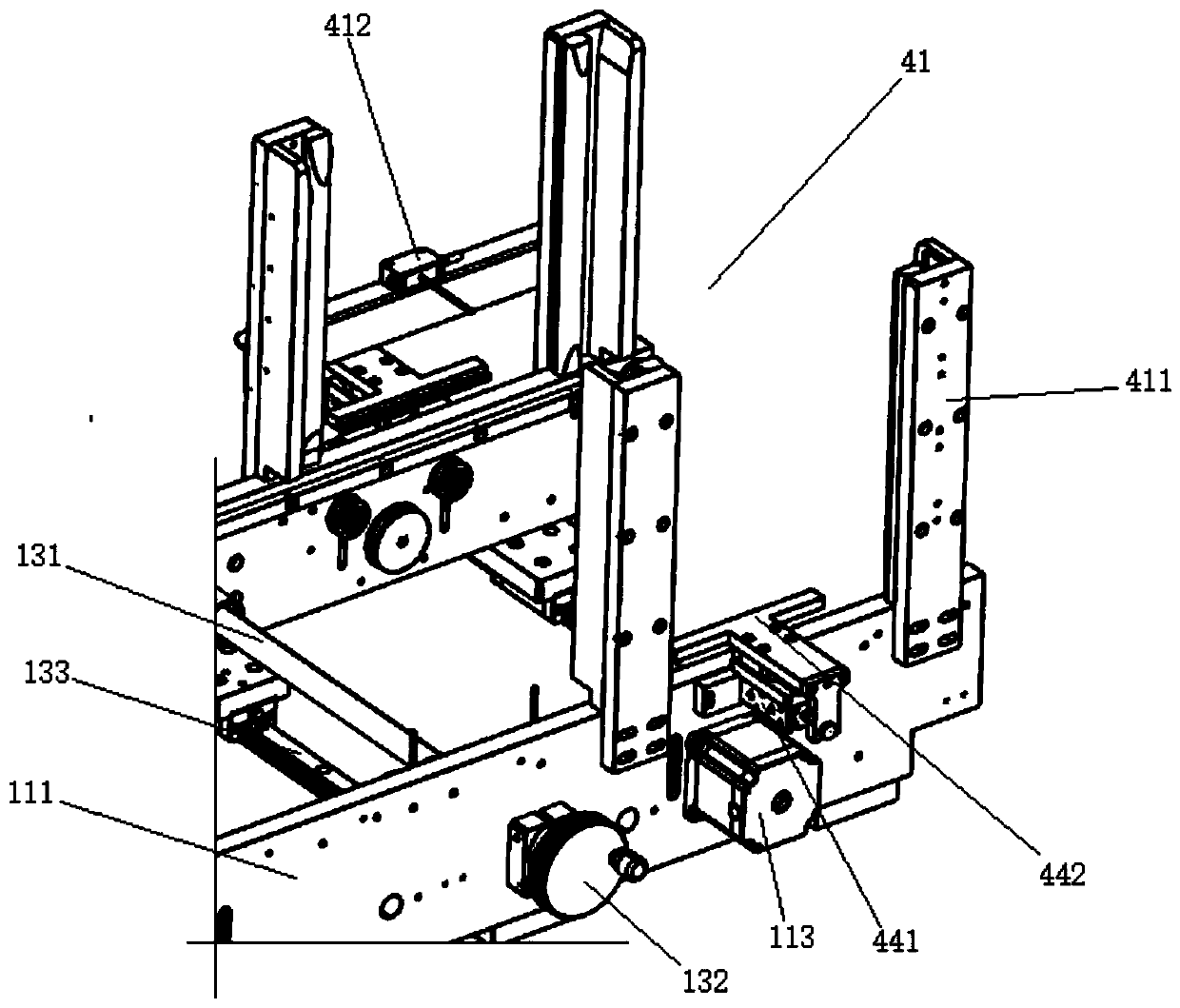

[0038] Please refer to Figure 1-Figure 8 , the present embodiment is an automatic feeding mechanism 100 for stacking trays to load circuit boards and embryo bodies, which includes tray conveying lines 1, NG conveying lines 2 and carrier conveying lines 3 arranged in parallel, respectively arranged on the trays The tray supply unit 4 and the empty tray recovery unit 5 at the front and rear ends of the conveying line 1, the tray positioning unit 6 arranged between the tray supply unit 4 and the empty tray recovery unit 5, the carrier arranged along the carrier conveying line 3 The tool supply unit 7 and the carrier positioning unit 8 , and the product transfer device 9 that grabs multiple products from the trays on the tray conveying line 1 and places them on the carriers on the carrier conveying line 3 one by one.

[0039] The tray conveying line 1 has the same structure as the carrier conveying line 3 and both include a first side conveying module 11, a second side conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com