Laser beam terminal pointing detection and correction method and laser processing device

A technology of laser beam and correction method, which is applied in the field of laser beam terminal pointing detection and correction, and laser processing device, can solve the problems of inability to monitor feedback correction online, and inability to guarantee the influence of laser beam, and achieve the effect of improving position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

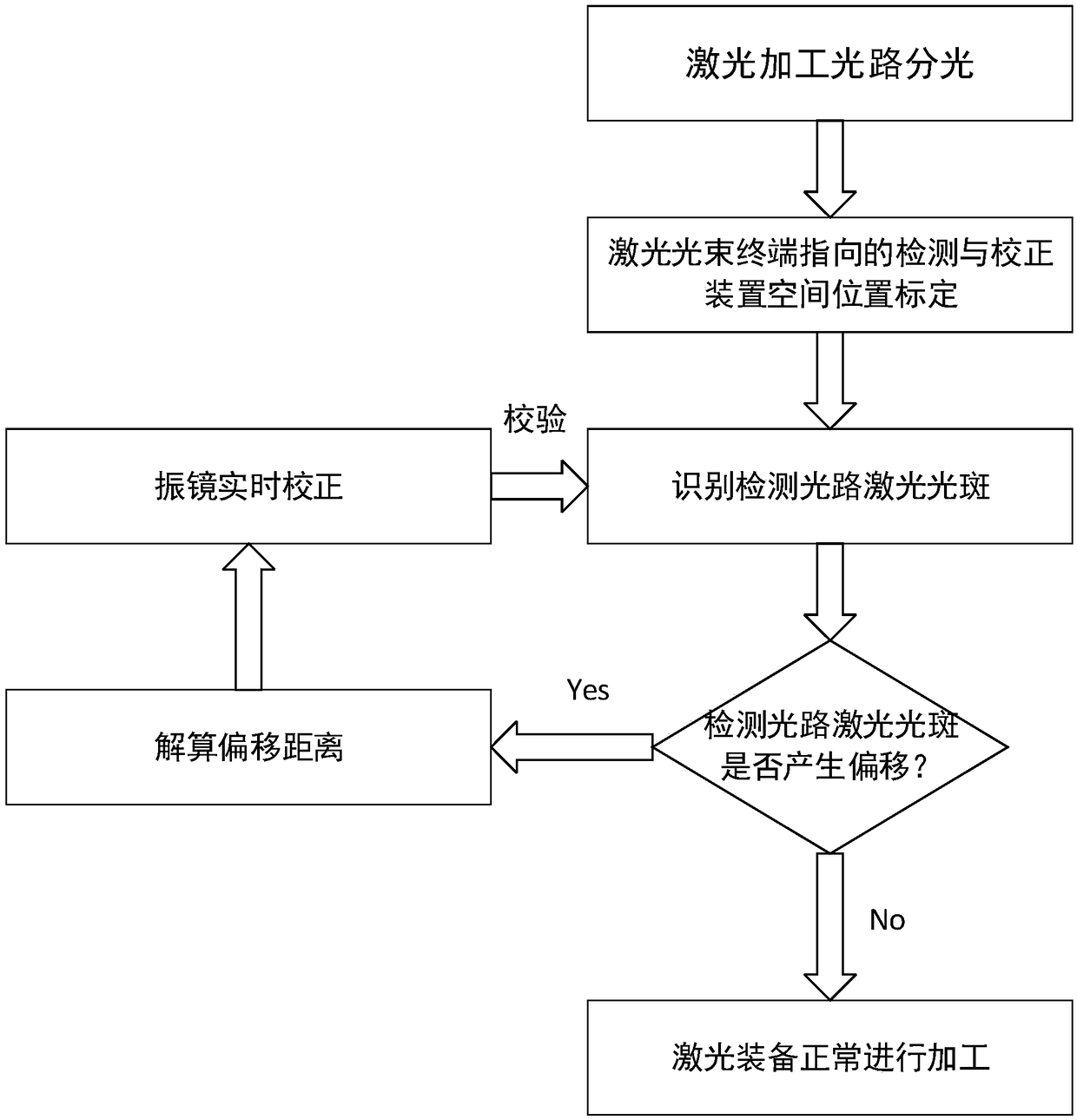

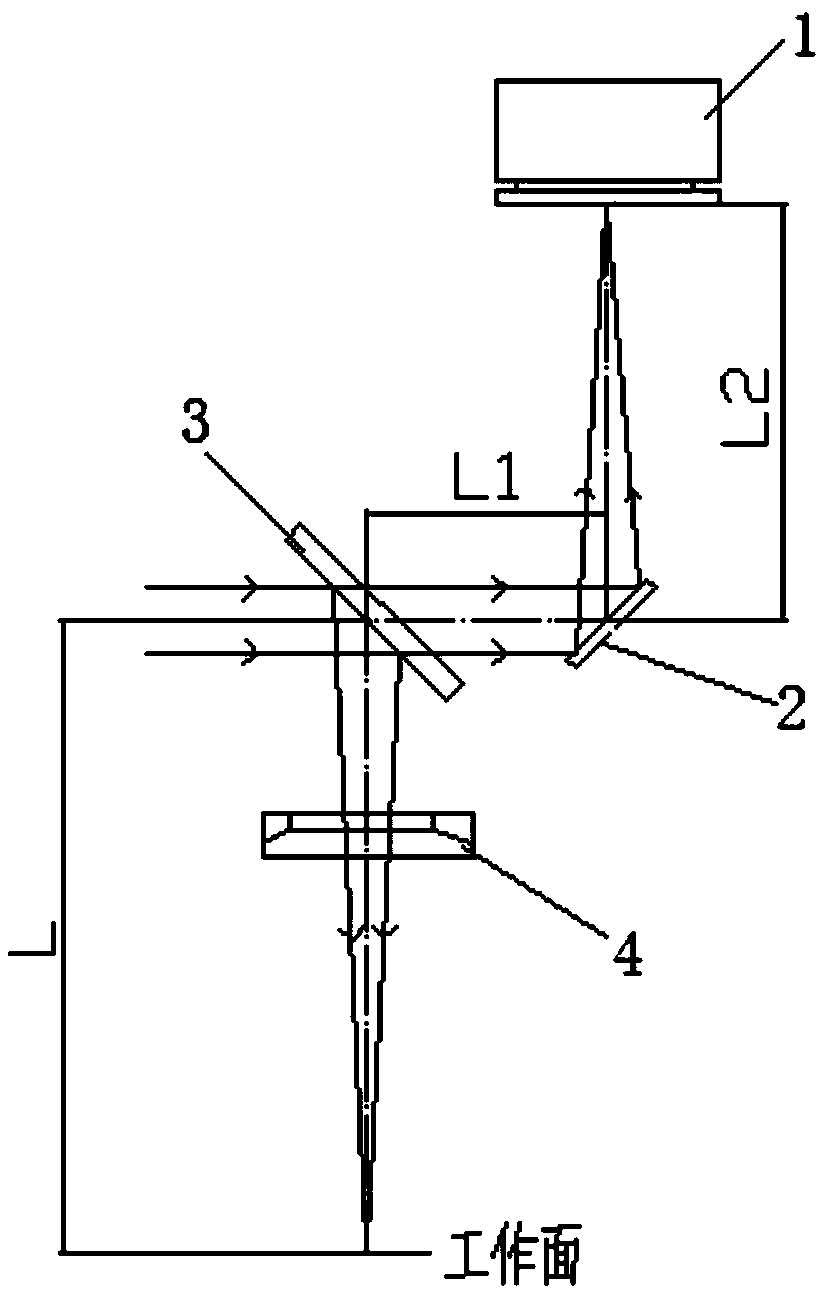

[0034] The laser beam terminal pointing detection and correction method of the present invention is used to solve the laser beam pointing at the processing terminal due to the long-time work of the laser equipment, the pointing deviation of the laser output beam, the temperature drift of the vibrating mirror and the timely drift in the laser processing process. Offset thus affects the position accuracy of the processed graphics. According to the principle of optical path conjugation, the spatial position of the detection and correction device of the laser beam terminal pointing is laid out and calibrated, so that the offset of the spot position in the field of view is equal to the offset of the actual laser processing spot position, so that the detection can be passed. The spot position of the device represents the spot shift of the laser-proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com