Galvano scanner and laser machining device

A technology of electronic scanner and light deflection, which is applied in laser welding equipment, metal processing equipment, instruments, etc., can solve problems such as errors, and achieve the effects of reducing surface tilt resonance and high position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

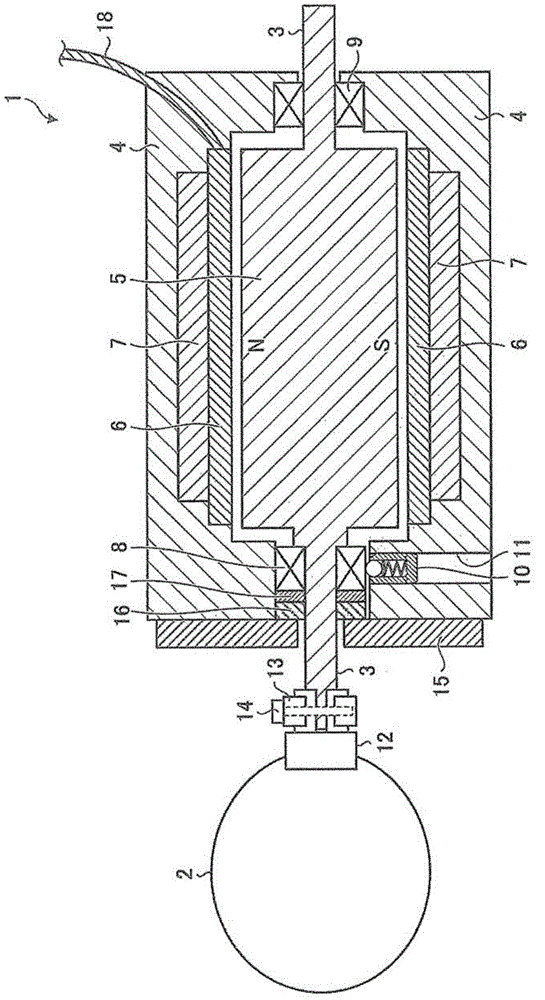

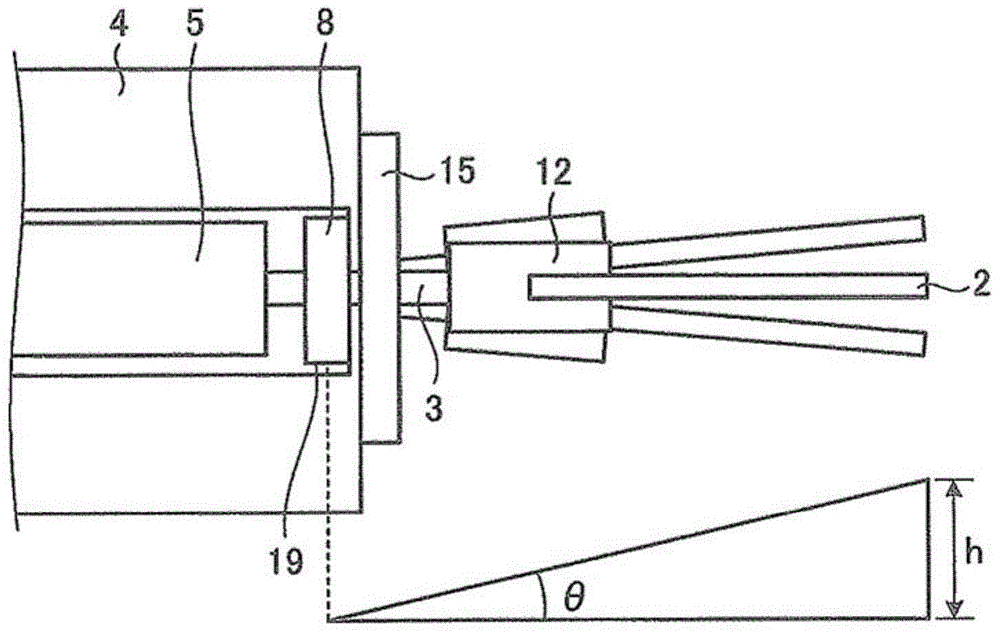

[0026] figure 1 It is a figure which shows the cross-sectional structure of the galvano scanner concerning Embodiment 1 of this invention. The galvano scanner 1 scans the laser light from the laser light source on the object to be processed. The galvano scanner 1 is composed of a rotating body and a fixed body.

[0027] The rotating body has a scanning mirror 2 , a rotating shaft 3 , and a magnet 5 . The rotary body is rotatable around the rotary shaft 3 . The scanning mirror 2 is a mirror that deflects incident light. The scanning mirror 2 is connected to one end on the front side of the rotating shaft 3 . The mirror mount 12 couples the scanning mirror 2 to the rotation shaft 3 . The mount pressing tool 13 fixes the mirror mount 12 to the rotation shaft 3 in a state where the fastener 14 is inserted. The magnet 5 is located between the front bearing 8 and the rear bearing 9 .

[0028] The fixed body has a frame case 4 , a winding 6 , and an iron core 7 . The winding ...

Embodiment approach 2

[0064] Figure 8 It is a figure which shows the cross-sectional structure of the galvano scanner concerning Embodiment 2 of this invention. The galvano scanner 30 scans the laser light from the laser light source on the object to be processed. The same reference numerals are assigned to the same parts as those in Embodiment 1, and overlapping descriptions are appropriately omitted.

[0065] A roller plunger 31 as a vibration suppressing structure is arranged in the through hole 11 . The roller plunger 31 suppresses the vibration of the front side bearing 8 caused by the driving of the rotary shaft 3 . The roller plunger 31 is screwed into the through hole 11 from the outer surface of the frame case 4 to be inserted into the through hole 11 .

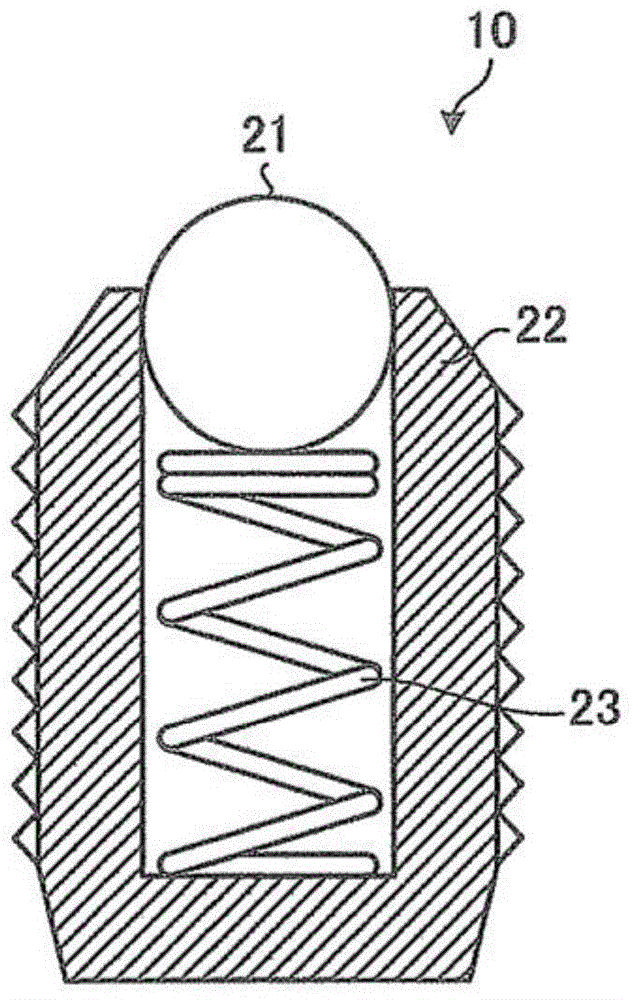

[0066] Figure 9 It is a figure which shows the cross-sectional structure of a roller plunger. The roller plunger 31 has a disk member 32 , a main body portion 33 , and a coil spring 34 . The main body portion 33 has a cylindrical ...

Embodiment approach 3

[0078] Figure 10 It is a figure which shows the cross-sectional structure of the galvano scanner concerning Embodiment 3 of this invention. The galvano scanner 40 scans the laser light from the laser light source on the object to be processed. The same reference numerals are assigned to the same parts as those in Embodiment 1, and overlapping descriptions are appropriately omitted.

[0079] A spring structure 41 as a vibration suppressing structure is inserted into the through hole 11 . The spring structure 41 suppresses the vibration of the front side bearing 8 caused by the driving of the rotating shaft 3 .

[0080] Figure 11 It is a side view in which the spring structure is disassembled. The spring structure 41 has a spring member 42 , a positioning member 43 , and a main body 44 . The spring member 42 as an elastic member is a contact member that contacts the outer peripheral side surface of the front side bearing 8 . The spring member 42 is, for example, a coil s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com