Position precision compensation method of ultra-precision two-dimensional motion platform system

A two-dimensional motion platform and motion platform technology, which are applied in the field of ultra-precision two-dimensional motion platform system position accuracy compensation and ultra-precision motion platform system, can solve the problems of insufficient accuracy of ordinary methods and strict position requirements, and achieve improved position accuracy. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

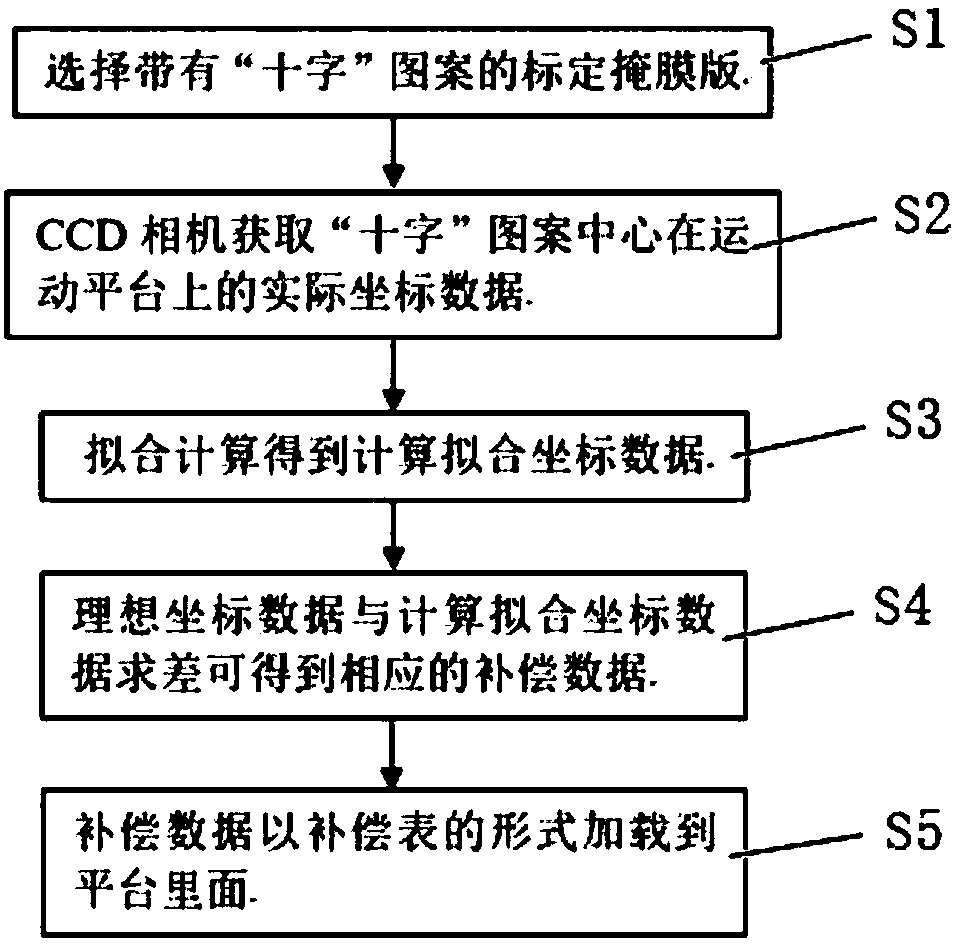

[0026] Such as figure 1 As shown, the position accuracy compensation method of the ultra-precision two-dimensional motion platform system includes the following specific steps:

[0027] S1. Select an optical calibration mask with a small processing error, which is mainly to etch a cross pattern or other symmetrical patterns that are evenly spaced in the horizontal and vertical directions on the chrome-plated quartz glass plate through an etching process, and then Place it within the area to be calibrated on the motion platform. In this embodiment, the horizontal and vertical spacing of the pattern is 5 mm, and the length and width of the calibration plate are both 140 mm, but it is not limited to this size, and a finer and wider range can be achieved.

[0028] S2. Use the CCD camera vision system to obtain the actual coordinate data of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com