Precompression method and equipment

A pre-pressing and pre-pressing wheel technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of waste chips, affecting product quality, and the chip is prone to position dislocation, etc., to improve position accuracy, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

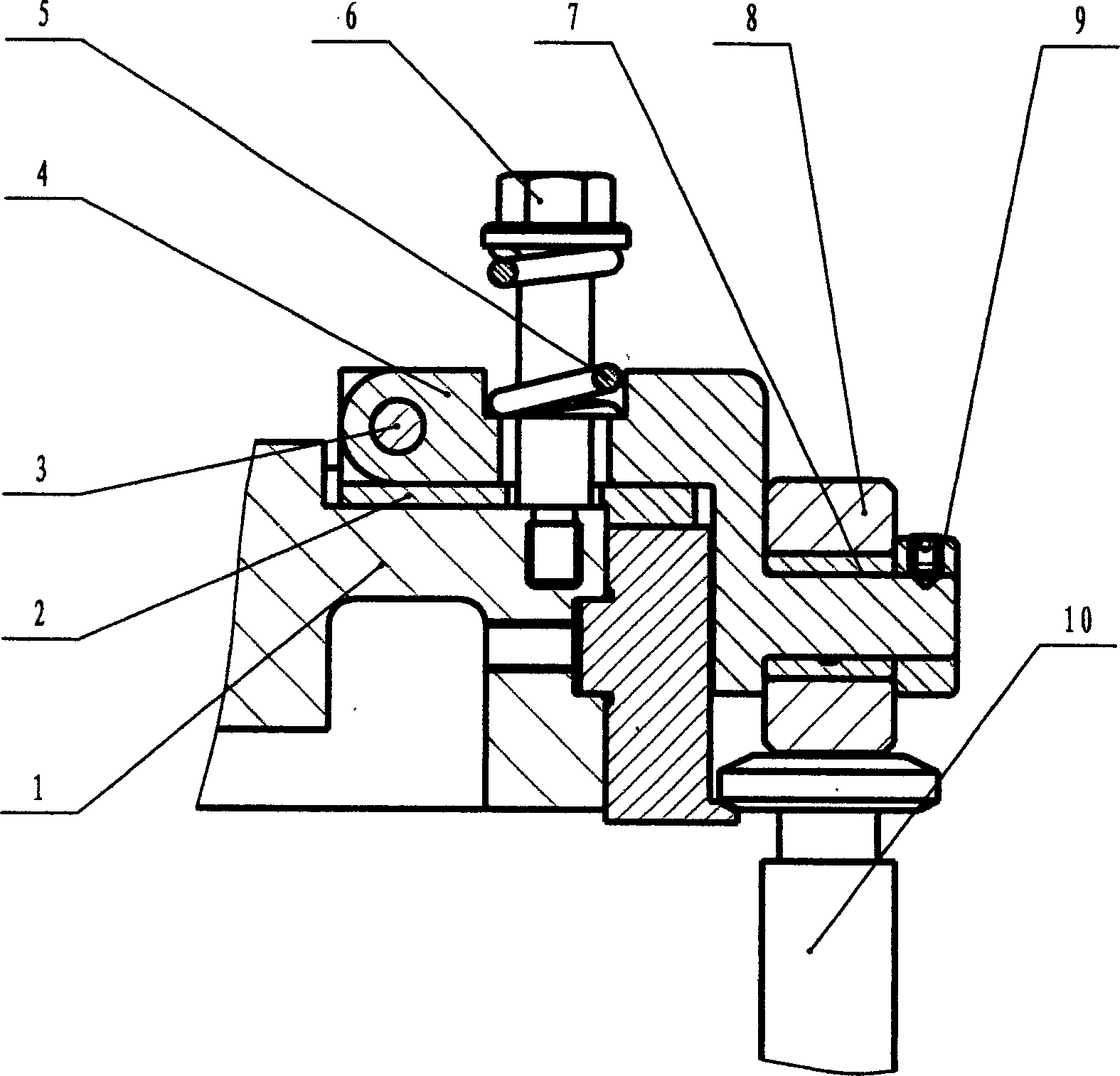

[0011] Further description will be made below with reference to the accompanying drawings and embodiments.

[0012] The method of adopting pre-compression on the rotary tablet press of the present invention is to add a pre-compression device in the compression mechanism of the rotary tablet press. That is, on the orbital disk of the rotary tablet press, a pre-pressing device is added behind the first filling device and the core-filling turntable, and before the second filling device, and the pre-pressing wheel (8) in the pre-pressing device is used to punch the nails The extrusion of (10) realizes the precise positioning of the chip, makes the radial position of the chip relatively fixed during the forming process, and improves the position accuracy of the chip.

[0013] The preloading device of the present invention is composed of preloading wheels, preloading wheel frames, fixing plates, adjusting screws, springs and other components. First put the copper sleeve (7) in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com