Special fixture for processing inclined conical nozzle steam passage and method thereof

A special fixture and steam channel technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of no inclined cone hole type nozzle steam channel, difficult centering of drill bits, etc., and achieves good results and guarantees The effect of high accuracy and positional precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

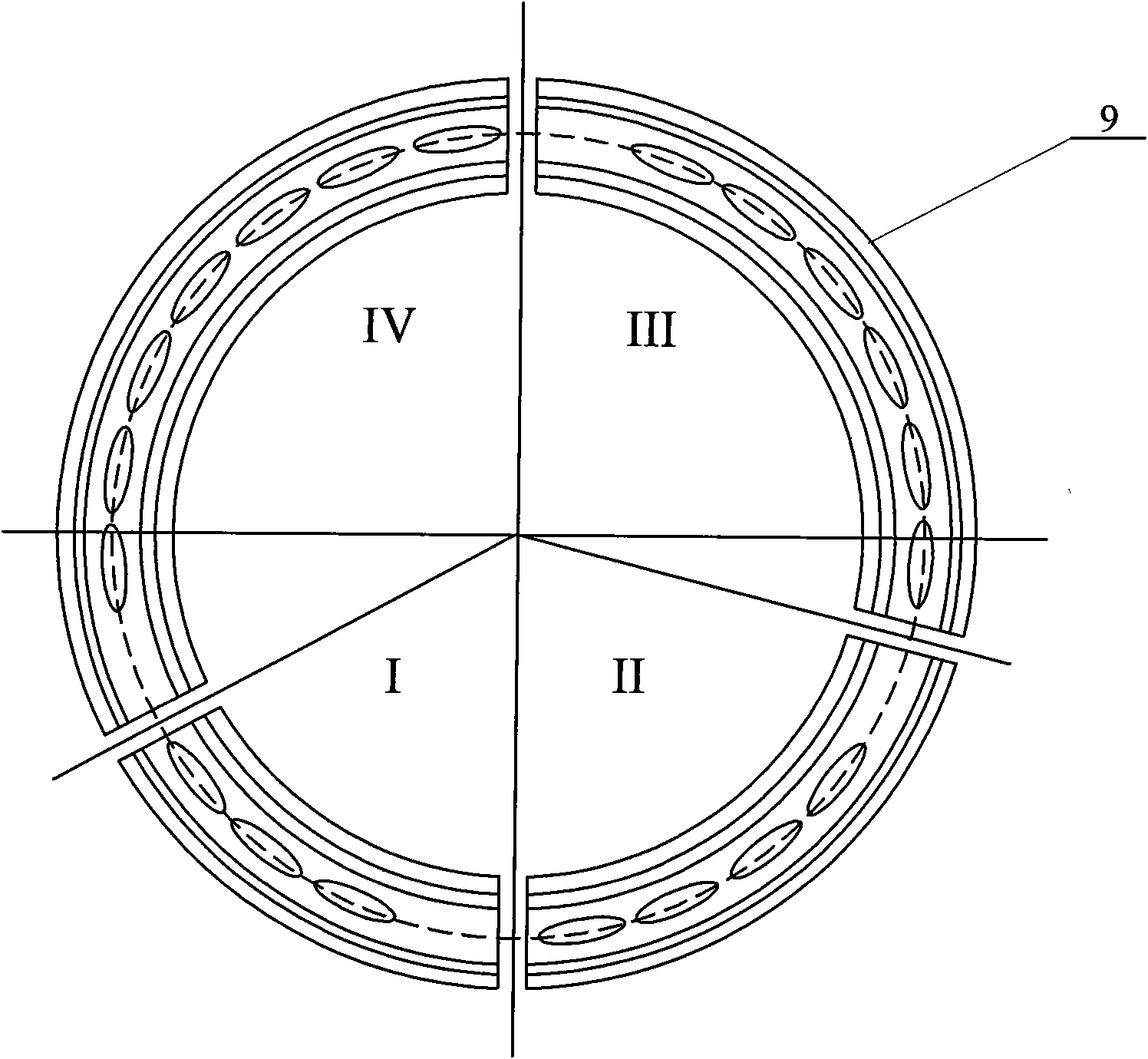

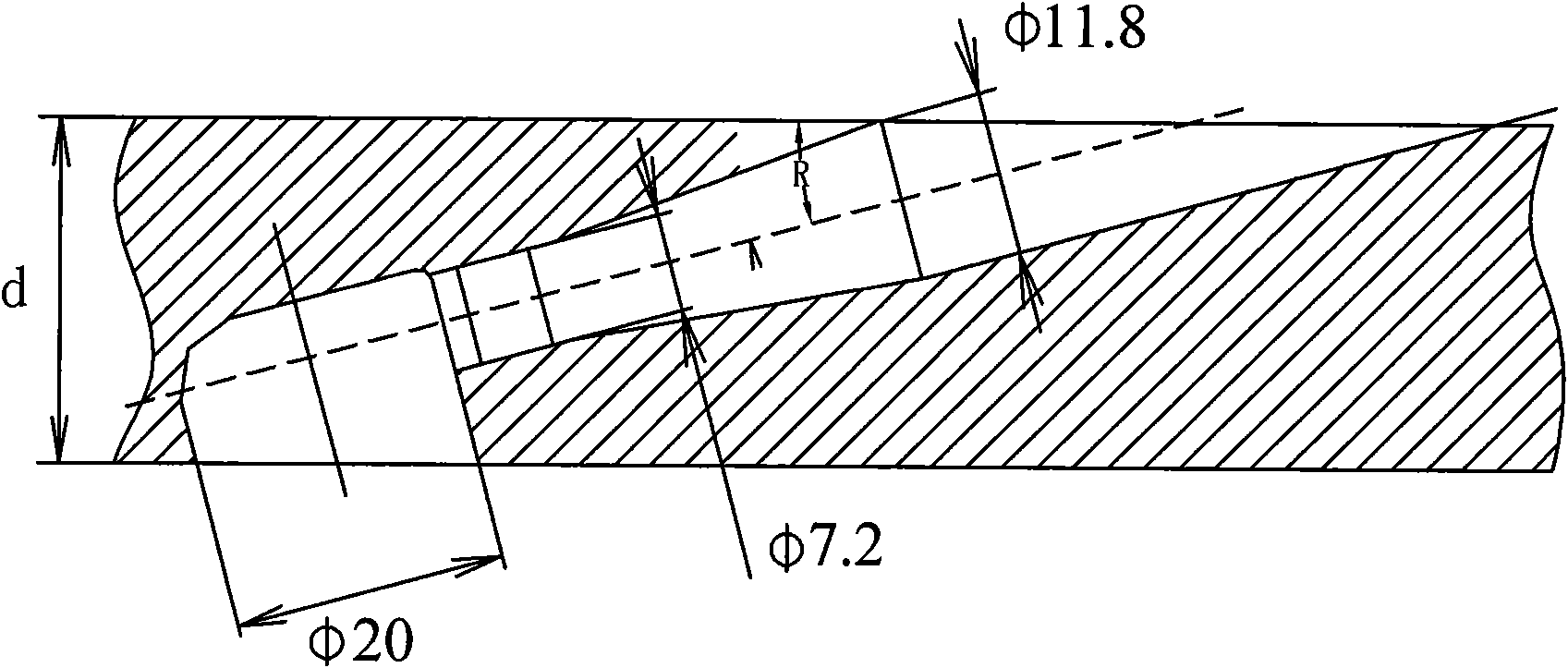

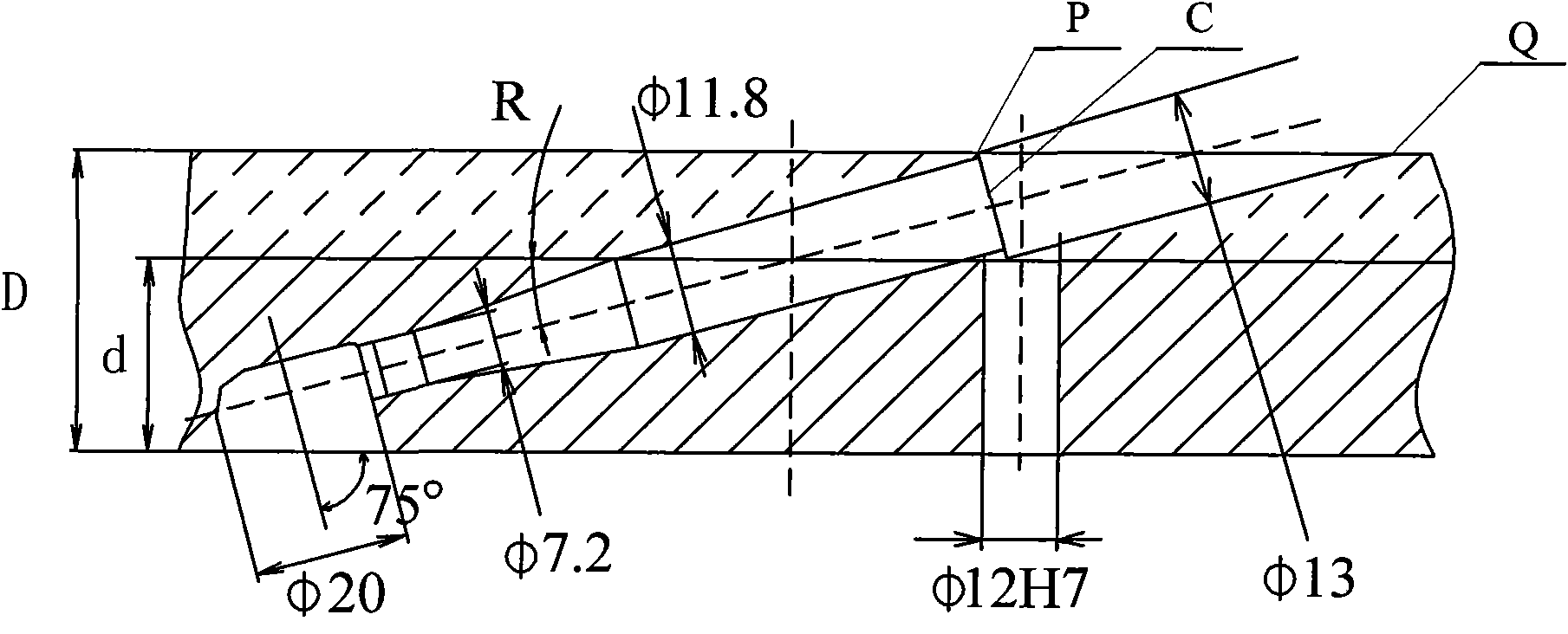

[0018] Specific implementation mode one: as Figure 4 As shown, the special fixture for processing the steam channel of the inclined cone-hole nozzle in this embodiment includes a fixture bending plate 1, a central shaft 2, an indexing plate 3, a positioning mandrel 6, three surrounding pressure plates 7 and a central pressure plate 8. The fixture bending plate 1 and the indexing plate 3 are sequentially set on the central shaft 2, and the central axis 2 is fixed on the fixture bending plate 1 by bolts. The fixture bending plate 1 has a stepped through hole 1-1, and the indexing plate 3 There are twenty indexing through holes 3-1 along the circumferential direction, the center of the stepped through hole 1-1 and the center of the indexing through hole 3-1 are on the same circle, and the positioning mandrel 6 is inserted in the On the index plate 3, the central pressing plate 8 is fixed on one end of the central shaft 2, and the surrounding pressing plates 7 are fixed on the fi...

specific Embodiment approach 2

[0019] Specific implementation mode two: as Figure 4 As shown, the special fixture described in this embodiment further includes support ribs 10 , and the support ribs 10 are arranged in the corners 11 outside the clamp bending plate 1 . With such a design, the support rib 10 can improve the stability of the fixture bent plate 1 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: as Figure 4 As shown, the special fixture in this embodiment further includes a thrust bearing 12 , and the thrust bearing 12 is sleeved on the central shaft 2 . Such a design can reduce friction and make the index plate 3 rotate more briskly. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com