Automatic clearance-removing double-worm speed reducer

A technology of double worm and reducer, which is applied in the direction of mechanical equipment, transmission devices, transmission device parts, etc., can solve the problems that the center distance cannot be adjusted, the processing quality and precision of machine tools are reduced, and solve the problems of low processing accuracy and high transmission accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

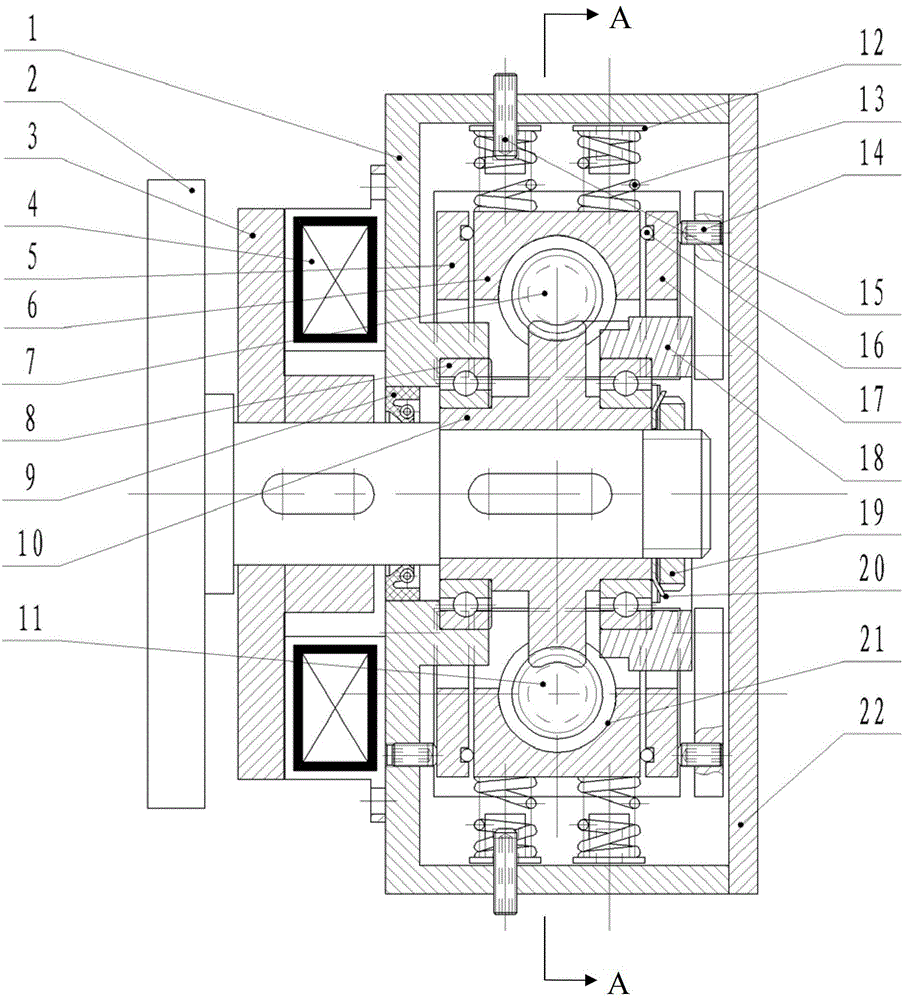

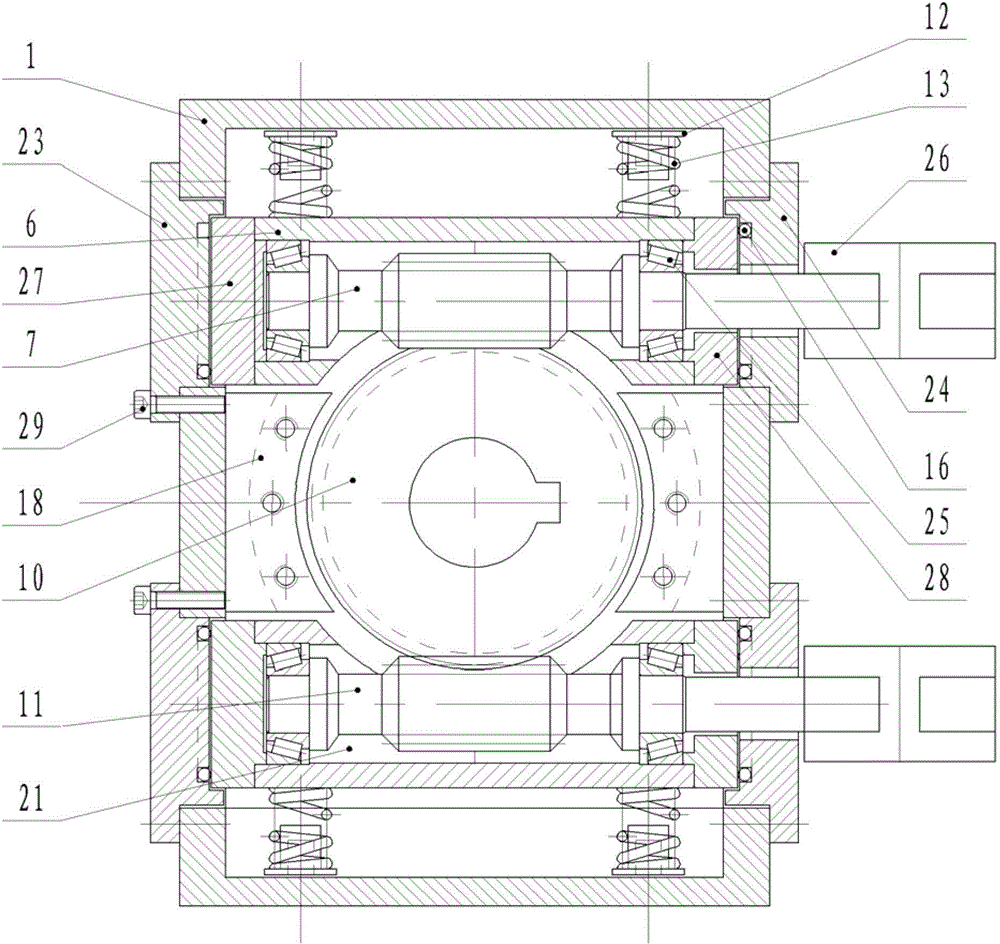

[0016] The present invention is described in detail below in conjunction with accompanying drawing

[0017] Such as figure 1 Shown, the upper worm (7) above is contained in a worm box (6) that can slide radially along the worm wheel (10), and the flexibility of sliding is guaranteed by balls (16). Four springs (13) are installed between the casing (1) and the worm box (6), which generate an elastic force pushing the worm box (6) toward the worm wheel (10), and can realize automatic alignment and automatic alignment during assembly. After finding the right position, use the adjusting screw (14) on the outside of the left adjustment plate (5) and the right adjustment plate (17) to ensure the correctness of the meshing position of the upper worm (7). The spring force-adjusting jackscrew (15) compresses the spring seat (12) and adjusts the force of the spring (13), thereby automatically adjusting the gap produced along with the rotation and wear of the worm wheel (10) and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com