Miniature multifunctional combined machining center

A compound machining center and multi-functional technology, applied in the field of CNC machine tools, can solve the problems of inability to provide space and foundation requirements for industrial machining centers, monotonous functions of industrial machining centers, poor efficiency and stability, etc., to achieve rich functions, flexible and controllable structure , The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

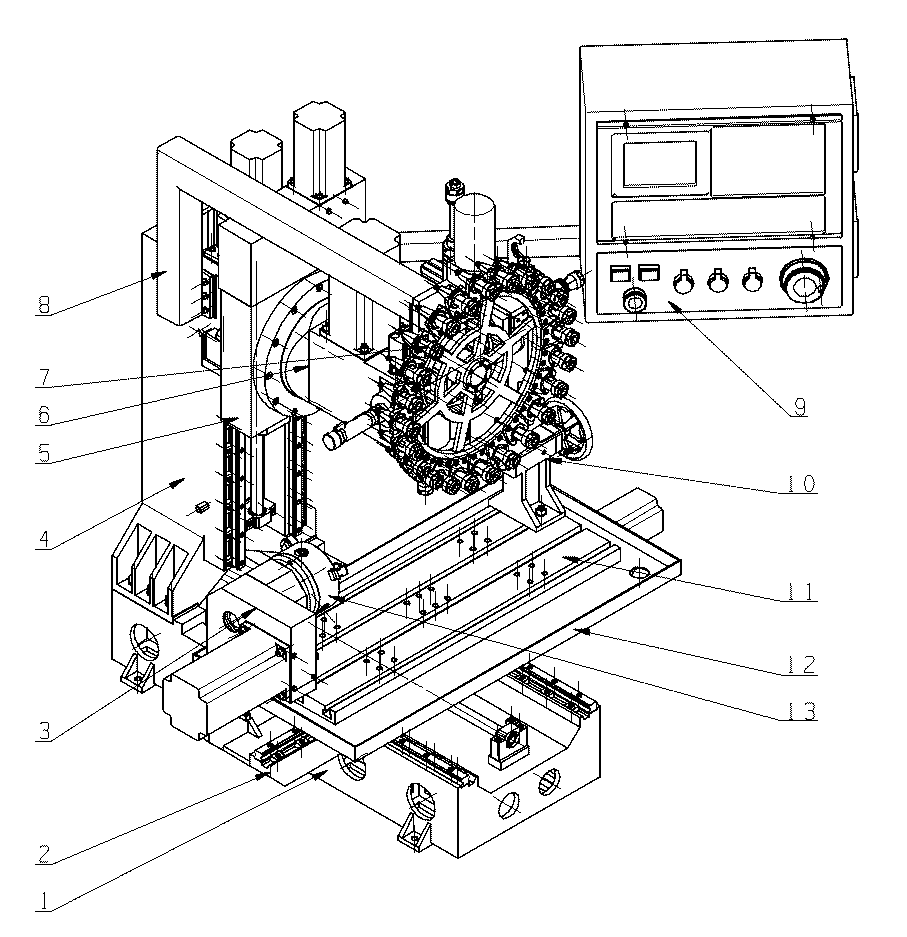

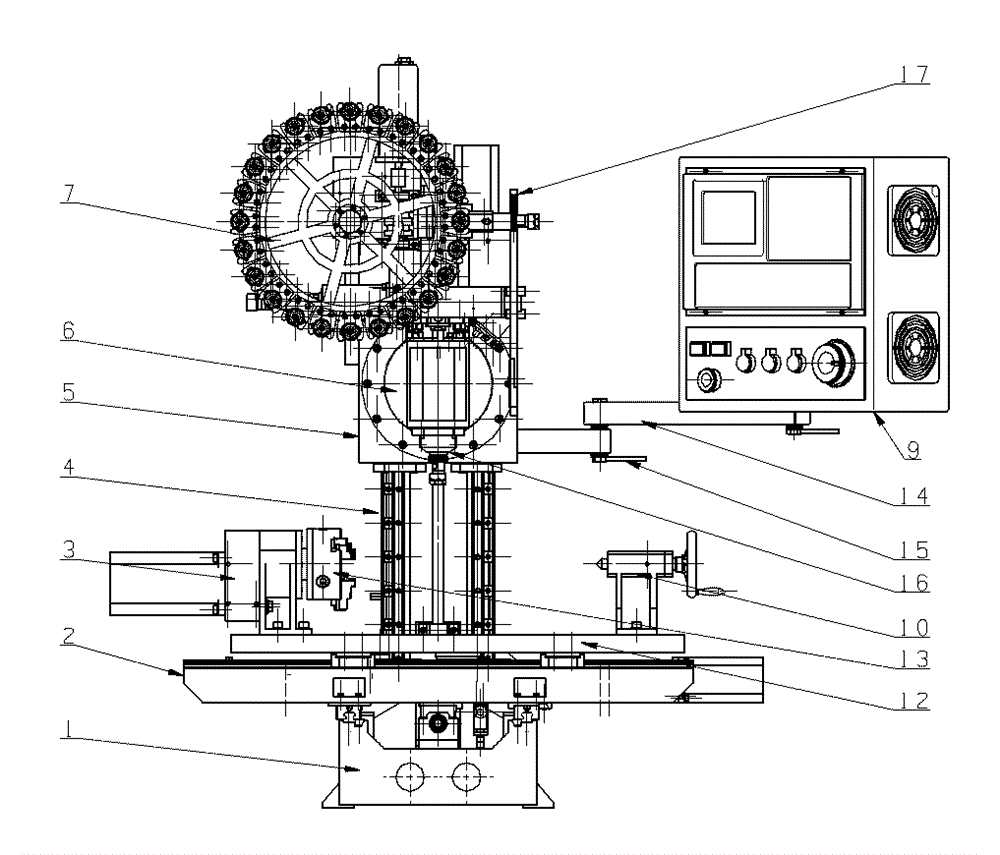

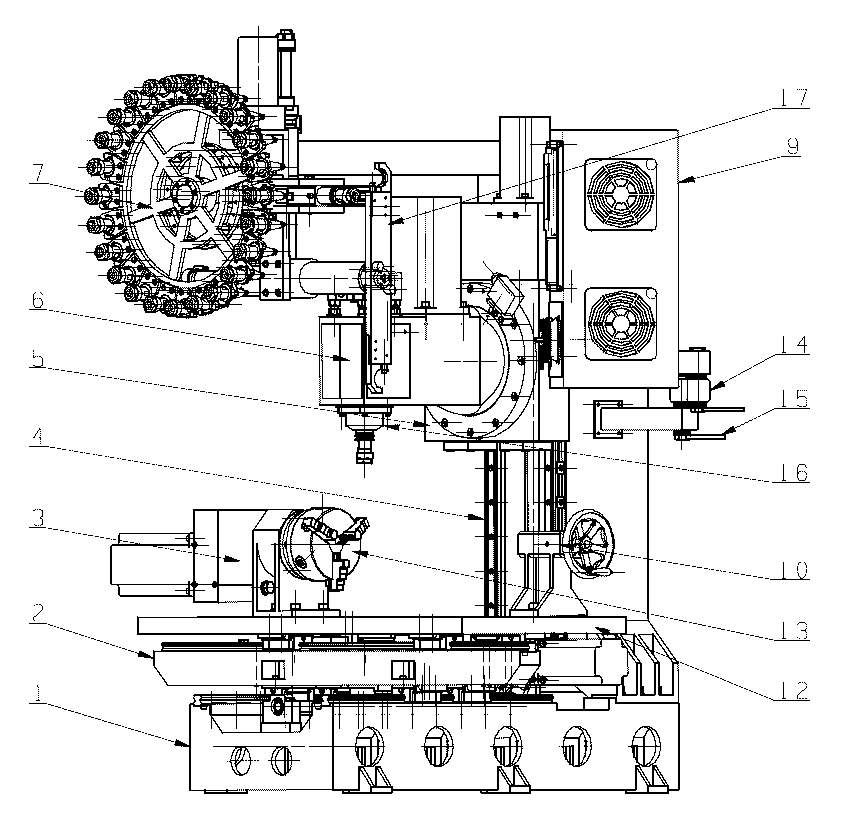

[0036] Such as figure 1 As shown, the present invention includes a machine tool base 1, an X-axis ram 2, a turning spindle (A-axis assembly) 3, a machine column 4, a B-axis worm gear box assembly 5, a headstock assembly 6, a tool magazine 7, a tool magazine bracket 8, CNC system 9, tail seat 10, worktable 11, oil pan 12, chuck 13, CNC system support 14, CNC system support locking mechanism 15, tool spindle 16, automatic tool exchange device mechanical arm 17, of which: workbench 11 X-axis moving part of the machine tool, X-axis ram 2 is the Y-axis moving part of the machine tool, B-axis worm gear box assembly 5 is the Z-axis moving part, chuck 13 is the A-axis moving part of the machine tool, and headstock assembly 6 is the B-axis movement part.

[0037] The tool magazine 7 is installed on the front of the machine tool, the headstock assembly 6 is at the highest po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com